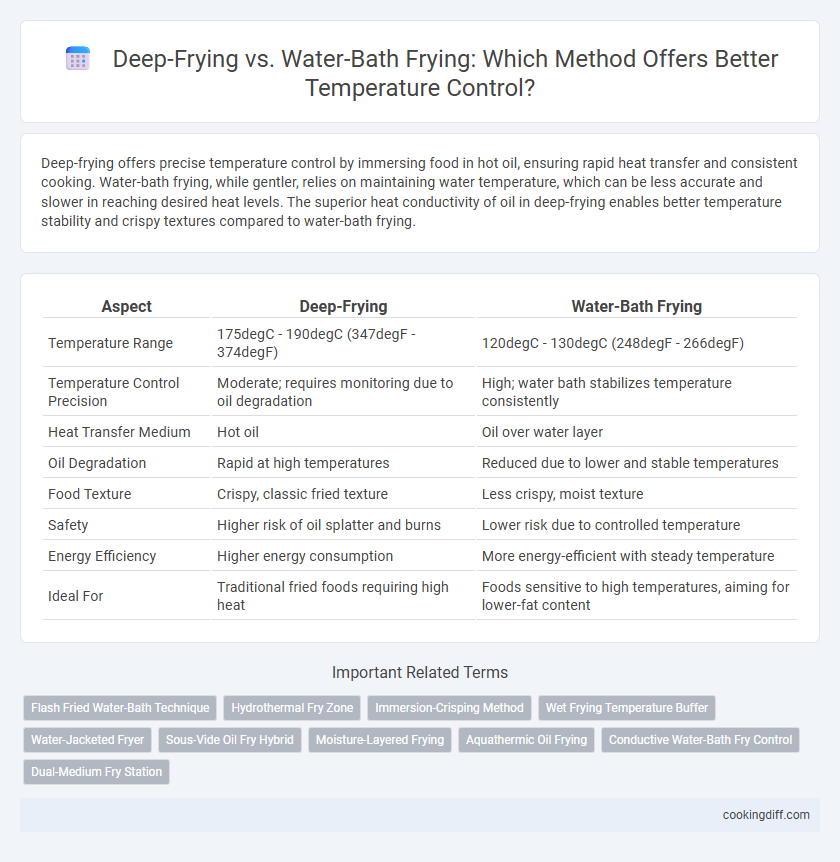

Deep-frying offers precise temperature control by immersing food in hot oil, ensuring rapid heat transfer and consistent cooking. Water-bath frying, while gentler, relies on maintaining water temperature, which can be less accurate and slower in reaching desired heat levels. The superior heat conductivity of oil in deep-frying enables better temperature stability and crispy textures compared to water-bath frying.

Table of Comparison

| Aspect | Deep-Frying | Water-Bath Frying |

|---|---|---|

| Temperature Range | 175degC - 190degC (347degF - 374degF) | 120degC - 130degC (248degF - 266degF) |

| Temperature Control Precision | Moderate; requires monitoring due to oil degradation | High; water bath stabilizes temperature consistently |

| Heat Transfer Medium | Hot oil | Oil over water layer |

| Oil Degradation | Rapid at high temperatures | Reduced due to lower and stable temperatures |

| Food Texture | Crispy, classic fried texture | Less crispy, moist texture |

| Safety | Higher risk of oil splatter and burns | Lower risk due to controlled temperature |

| Energy Efficiency | Higher energy consumption | More energy-efficient with steady temperature |

| Ideal For | Traditional fried foods requiring high heat | Foods sensitive to high temperatures, aiming for lower-fat content |

Introduction to Deep-frying and Water-bath Frying

Deep-frying involves immersing food in hot oil, typically between 350degF to 375degF, allowing for rapid cooking and crispy textures. Precise temperature control is essential to prevent oil degradation and ensure even cooking.

Water-bath frying uses a combination of hot oil over a temperature-controlled water bath, maintaining consistent heat usually below 212degF. This method reduces oil absorption and minimizes the risk of overheating compared to traditional deep-frying.

Understanding Temperature Control in Frying Methods

Deep-frying maintains a consistent oil temperature typically between 350degF and 375degF, allowing rapid cooking and the creation of a crispy texture. Water-bath frying uses a controlled water temperature below 212degF to regulate the oil temperature, preventing overheating and reducing oil degradation.

Understanding temperature control in deep-frying is crucial for achieving optimal cooking results and food safety. Deep-frying's higher temperatures promote Maillard reactions, resulting in browning and flavor development. Water-bath frying provides gentler heat transfer, enabling precise temperature regulation that minimizes nutrient loss and reduces acrylamide formation.

How Deep-frying Maintains Oil Temperature

| Deep-frying maintains oil temperature by submerging food in hot oil, typically around 350degF to 375degF, allowing consistent heat distribution. The high thermal mass of oil quickly recovers after food is added, preventing significant temperature drops. This precise temperature control ensures even cooking and a crisp, golden exterior. |

Precision of Water-bath Frying for Consistent Results

Water-bath frying offers unparalleled precision in temperature control by immersing food in a regulated water bath, maintaining a consistent frying temperature typically between 140degC to 160degC (284degF to 320degF). This precise control minimizes temperature fluctuations common in traditional deep-frying, resulting in evenly cooked food with reduced oil degradation and better texture retention.

In contrast, deep-frying directly in oil often leads to temperature variations due to oil absorption and food load changes, impacting the quality and safety of the final product. The stable thermal environment in water-bath frying enhances repeatability and consistency, making it ideal for industrial food processing and high-quality culinary applications.

Temperature Fluctuations: Deep-frying vs Water-bath Frying

Deep-frying involves immersing food in hot oil at temperatures typically between 160degC and 190degC, leading to rapid cooking with relatively stable temperature due to the high heat capacity of oil. Water-bath frying maintains a precise temperature by cooking food in oil at temperatures close to the water bath, resulting in reduced temperature fluctuations and more uniform heat distribution.

- Deep-frying temperature fluctuations - Can occur when large batches of food are added, causing oil temperature to drop temporarily before stabilizing.

- Water-bath frying temperature control - Relies on water temperature to regulate oil heat, minimizing sudden temperature swings.

- Impact on cooking consistency - Water-bath frying provides more consistent results due to controlled temperature, while deep-frying may have variable texture from oil temperature changes.

Water-bath frying offers superior temperature stability compared to traditional deep-frying, enhancing cooking precision and food quality.

Impact on Food Texture and Crispiness

How does temperature control in deep-frying compare to water-bath frying regarding food texture and crispiness? Deep-frying at high temperatures rapidly dehydrates the food surface, creating a crispy, golden crust that locks in moisture. Water-bath frying, with its precise lower temperature regulation, prevents burning but may produce less crispiness due to reduced Maillard reaction intensity.

Safety Considerations in Temperature Regulation

Deep-frying requires precise temperature control to prevent oil overheating, which can lead to fire hazards and harmful smoke emissions. Water-bath frying offers a safer alternative by using a controlled water temperature to indirectly regulate oil heat, reducing the risk of oil reaching dangerous temperatures. Proper monitoring and equipment calibration are essential in both methods to maintain safe frying conditions and avoid accidents in commercial and home kitchens.

Equipment Needed for Accurate Temperature Control

Deep-frying requires specialized equipment such as thermostatically controlled electric fryers or heavy-duty gas fryers for precise temperature maintenance between 325degF and 375degF. Water-bath frying utilizes a water-filled pan beneath the frying vessel to evenly regulate heat, demanding less sophisticated but carefully monitored equipment like double boilers or steam-jacketed kettles. Accurate temperature control in deep-frying equipment prevents oil degradation and ensures consistent food texture and safety.

Energy Efficiency in Deep-frying and Water-bath Frying

Deep-frying typically consumes more energy than water-bath frying due to higher temperature requirements and longer heat retention times. Water-bath frying offers enhanced temperature control, which can reduce overall energy usage by maintaining a consistent, lower temperature.

- Higher Energy Consumption in Deep-frying - Deep-frying requires maintaining oil at temperatures around 175-190degC, leading to increased energy demand compared to water-bath frying.

- Temperature Stability in Water-bath Frying - Water-bath frying uses water as a heat buffer, ensuring stable temperatures and minimizing energy spikes during cooking.

- Energy Efficiency Optimization - Water-bath frying's precise temperature control reduces thermal losses, resulting in better energy efficiency versus traditional deep-frying methods.

Related Important Terms

Flash Fried Water-Bath Technique

Flash Fried Water-Bath Technique offers precise temperature control by submerging food in hot water before a quick oil flash, reducing the risk of overheating and excessive oil absorption compared to traditional deep-frying. This method preserves texture and color while ensuring consistent cooking temperature, enhancing food quality and safety.

Hydrothermal Fry Zone

The Hydrothermal Fry Zone in deep-frying maintains consistent oil temperature above 170degC, ensuring rapid crust formation and moisture retention, whereas water-bath frying regulates heat around 100degC, limiting the Maillard reaction and resulting in less crisp texture. Precise temperature control in the Hydrothermal Fry Zone enhances food quality by optimizing heat transfer rates and reducing oil absorption compared to water-bath frying methods.

Immersion-Crisping Method

The Immersion-Crisping Method in deep-frying ensures precise temperature control by fully submerging food in hot oil, promoting rapid and even heat transfer that achieves optimal crispness. Compared to water-bath frying, this technique prevents temperature fluctuations caused by water vapor, resulting in consistent texture and enhanced flavor development.

Wet Frying Temperature Buffer

Wet frying temperature buffer in water-bath frying maintains a more stable cooking temperature by surrounding food with heated water, reducing temperature fluctuations seen in deep-frying. This method prevents overheating and ensures precise temperature control, leading to consistent texture and moisture retention compared to traditional oil temperature spikes in deep-frying.

Water-Jacketed Fryer

Water-jacketed fryers provide superior temperature control compared to traditional deep-frying by using a circulating water jacket to maintain consistent heat, reducing temperature fluctuations that can degrade oil quality. This method enhances food texture and safety while extending oil life, making water-bath frying an energy-efficient and precise alternative for commercial frying operations.

Sous-Vide Oil Fry Hybrid

Sous-vide oil fry hybrid combines precise temperature control of water-bath frying with the rapid heat transfer of deep-frying, ensuring consistent cooking and crispy textures. This method reduces oil degradation and improves food quality by maintaining optimal frying temperatures below 200degC, unlike traditional deep-frying that often fluctuates between 170degC and 190degC.

Moisture-Layered Frying

Deep-frying achieves precise temperature control by immersing food directly in hot oil at temperatures between 160-190degC, creating a rapid moisture-layered crust that seals in internal juices and ensures a crispy exterior. Water-bath frying uses a controlled water bath at lower temperatures beneath the oil, maintaining consistent heat and preventing overheating, which results in more even cooking and reduced oil degradation while preserving moisture within the food.

Aquathermic Oil Frying

Aquathermic oil frying combines deep-frying's high-temperature benefits with water-bath frying's precise temperature control by circulating heated oil above a water layer, maintaining consistent heat and preventing oil degradation. This method enhances food texture and reduces harmful compound formation compared to traditional deep-frying, while offering superior temperature stability over conventional water-bath frying.

Conductive Water-Bath Fry Control

Conductive water-bath frying ensures precise temperature control by submerging food in a heated water medium, allowing even heat distribution and minimizing the risk of overheating compared to conventional deep-frying. This method enhances product quality by maintaining consistent frying temperatures, reducing oil degradation and promoting uniform cooking.

Deep-frying vs Water-bath frying for temperature control. Infographic

cookingdiff.com

cookingdiff.com