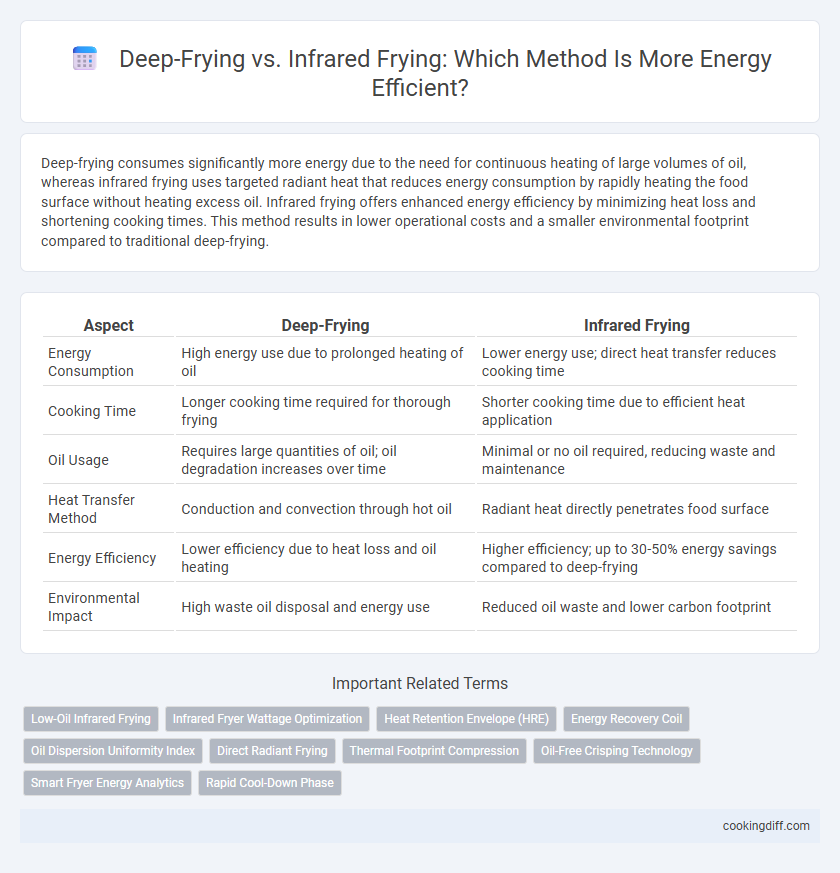

Deep-frying consumes significantly more energy due to the need for continuous heating of large volumes of oil, whereas infrared frying uses targeted radiant heat that reduces energy consumption by rapidly heating the food surface without heating excess oil. Infrared frying offers enhanced energy efficiency by minimizing heat loss and shortening cooking times. This method results in lower operational costs and a smaller environmental footprint compared to traditional deep-frying.

Table of Comparison

| Aspect | Deep-Frying | Infrared Frying |

|---|---|---|

| Energy Consumption | High energy use due to prolonged heating of oil | Lower energy use; direct heat transfer reduces cooking time |

| Cooking Time | Longer cooking time required for thorough frying | Shorter cooking time due to efficient heat application |

| Oil Usage | Requires large quantities of oil; oil degradation increases over time | Minimal or no oil required, reducing waste and maintenance |

| Heat Transfer Method | Conduction and convection through hot oil | Radiant heat directly penetrates food surface |

| Energy Efficiency | Lower efficiency due to heat loss and oil heating | Higher efficiency; up to 30-50% energy savings compared to deep-frying |

| Environmental Impact | High waste oil disposal and energy use | Reduced oil waste and lower carbon footprint |

Introduction to Deep-Frying and Infrared Frying

Deep-frying is a traditional cooking method that uses hot oil to quickly cook food, resulting in a crispy texture and rich flavor. It requires high energy consumption due to the continuous heating of large oil volumes.

Infrared frying utilizes infrared radiation to heat food directly, significantly reducing energy use by eliminating the need to heat excess oil. This method offers improved energy efficiency and faster cooking times compared to conventional deep-frying.

How Deep-Frying Works: Energy Consumption Overview

Deep-frying cooks food by submerging it in hot oil, typically between 175degC and 190degC, which requires continuous energy input to maintain oil temperature. This process results in significant energy consumption due to heat loss from oil exposure and prolonged heating times.

- Heat transfer efficiency - Deep-frying relies on conduction between hot oil and food, leading to moderate energy efficiency but with notable heat dissipation into the environment.

- Oil heating energy use - Maintaining high oil temperature demands constant energy, accounting for the majority of consumption in deep-frying operations.

- Infrared frying comparison - Infrared frying uses radiant heat that reduces heat loss by direct energy transfer, often improving overall energy efficiency versus traditional deep-frying.

Deep-frying's energy intensity stems from the need to heat and sustain a large volume of oil, making alternative methods like infrared frying more energy-efficient options in certain applications.

Infrared Frying Technology Explained

Infrared frying technology uses radiant heat to cook food more efficiently by directly heating the surface, resulting in reduced energy consumption compared to traditional deep-frying methods. This approach minimizes oil absorption and shortens cooking times, making it a more sustainable option for commercial and home kitchens.

- Direct Heat Transfer - Infrared fryers emit infrared radiation that penetrates food, providing fast and consistent cooking without needing to heat large volumes of oil.

- Energy Savings - Infrared cooking can reduce energy use by up to 30% compared to conventional deep-frying due to selective heating and shorter cooking cycles.

- Health and Quality Benefits - Less oil absorption and lower temperatures help maintain food texture and nutritional value while reducing harmful byproducts often formed in deep-frying.

Comparing Energy Efficiency: Deep-Frying vs Infrared Frying

Deep-frying consumes significantly more energy due to the need to heat large volumes of oil to high temperatures, resulting in longer cooking times and higher heat loss. Infrared frying uses radiant heat to directly cook food, reducing energy consumption by up to 40% compared to traditional deep-frying methods.

Infrared frying provides faster heat transfer and maintains consistent temperature control, improving overall energy efficiency in commercial kitchens. In contrast, deep-frying often requires continuous oil heating, increasing energy demand and operational costs.

Heat Transfer Methods: Oil vs Infrared

Deep-frying relies on convection heat transfer through hot oil, which absorbs and transfers heat uniformly to food, resulting in high energy consumption due to oil heating and maintenance. Infrared frying uses radiant heat to directly cook food surfaces with targeted energy application, reducing heat loss and improving energy efficiency by eliminating the need to heat large volumes of oil. Comparing heat transfer methods, infrared frying offers faster heat penetration and precise temperature control, minimizing energy waste compared to traditional oil convection in deep-frying.

Cooking Times and Temperature Control

Infrared frying offers precise temperature control, reducing overheating and energy waste compared to traditional deep-frying methods. Cooking times with infrared frying are often shorter due to direct heat penetration, enhancing energy efficiency in food preparation.

- Faster Cooking Times - Infrared frying typically cuts cooking times by up to 30%, minimizing energy consumption.

- Accurate Temperature Control - Infrared technology maintains consistent temperatures, preventing oil degradation and energy inefficiency.

- Lower Energy Use - Reduced cooking duration and precise heating lead to significant reductions in overall energy usage.

Oil Usage and Energy Implications

| Frying Method | Oil Usage | Energy Consumption |

|---|---|---|

| Deep-frying | High oil volume required to immerse food completely, leading to increased oil absorption and frequent oil replacement. | Consumes more energy due to prolonged heating times and maintaining a large oil temperature, resulting in higher overall energy costs. |

| Infrared frying | Minimal oil usage as food is cooked using infrared radiation, reducing oil absorption and waste. | Lower energy consumption achieved by directly heating food surfaces without preheating large oil quantities, enhancing energy efficiency. |

Environmental Impact and Sustainability

How does energy consumption compare between deep-frying and infrared frying in terms of environmental impact? Infrared frying uses significantly less energy than traditional deep-frying because it directly heats food surfaces, reducing cooking time and oil usage. This energy efficiency leads to lower carbon emissions and less environmental waste, making infrared frying a more sustainable choice for commercial kitchens.

Cost Analysis: Energy Bills and Equipment

Deep-frying consumes significantly more energy than infrared frying due to prolonged heating times and higher oil temperatures, leading to increased energy bills. Infrared frying equipment operates at optimized energy levels, reducing electricity costs by up to 40% compared to traditional deep-fryers.

Cost analysis reveals that while infrared frying systems may have higher upfront equipment expenses, the substantial reduction in energy consumption lowers operational costs over time. Businesses using infrared frying report a faster return on investment due to decreased maintenance and shorter cooking cycles. Energy-efficient infrared technology also minimizes heat loss, further enhancing cost savings in commercial kitchens.

Related Important Terms

Low-Oil Infrared Frying

Low-oil infrared frying significantly reduces energy consumption by utilizing infrared radiation to rapidly heat food surfaces with minimal oil, outperforming traditional deep-frying methods that require large volumes of hot oil and prolonged heating times. This innovative technique not only enhances energy efficiency but also minimizes oil usage, promoting healthier cooking while maintaining desirable texture and flavor.

Infrared Fryer Wattage Optimization

Infrared frying optimizes energy efficiency by utilizing lower wattage compared to traditional deep-frying, reducing power consumption by up to 40% while maintaining consistent heat distribution. This wattage optimization minimizes energy waste and enhances cooking speed, resulting in cost-effective operation and improved environmental impact.

Heat Retention Envelope (HRE)

Deep-frying typically exhibits lower energy efficiency compared to infrared frying due to substantial heat loss from oil exposure, while infrared frying benefits from a superior Heat Retention Envelope (HRE) that minimizes heat dissipation and optimizes energy usage. The enhanced HRE in infrared frying systems ensures faster temperature recovery and reduced energy consumption, resulting in more sustainable cooking processes.

Energy Recovery Coil

Energy Recovery Coils in infrared frying systems significantly enhance energy efficiency by capturing and repurposing residual heat, reducing overall energy consumption compared to traditional deep-frying methods. This innovative heat recovery technology optimizes thermal exchange, resulting in lower operational costs and improved sustainable frying performance.

Oil Dispersion Uniformity Index

Infrared frying demonstrates a higher Oil Dispersion Uniformity Index compared to traditional deep-frying, indicating more consistent oil distribution and reduced oil consumption. This improved uniformity enhances energy efficiency by minimizing heat loss and optimizing frying temperatures throughout the process.

Direct Radiant Frying

Direct Radiant Frying uses infrared radiation to cook food, significantly reducing energy consumption compared to traditional deep-frying by eliminating the need to heat large volumes of oil. This method delivers faster heat transfer and precise temperature control, enhancing energy efficiency and minimizing oil degradation during the frying process.

Thermal Footprint Compression

Infrared frying significantly reduces the thermal footprint compared to traditional deep-frying by directly heating the food surface, minimizing heat loss and energy consumption. This targeted thermal footprint compression results in faster cooking times and improved energy efficiency, lowering overall operational costs in commercial kitchens.

Oil-Free Crisping Technology

Infrared frying uses Oil-Free Crisping Technology, reducing energy consumption by up to 50% compared to traditional deep-frying methods that rely on large volumes of heated oil. This technology eliminates the need for oil filtration and disposal, enhancing sustainability while delivering comparable crispiness and texture in fried foods.

Smart Fryer Energy Analytics

Smart Fryer Energy Analytics reveals that infrared frying reduces energy consumption by up to 40% compared to traditional deep-frying, optimizing heat transfer and minimizing oil preheating time. Infrared frying also ensures consistent temperature control and faster cooking cycles, significantly lowering overall energy costs in commercial kitchens.

Deep-frying vs Infrared frying for energy efficiency. Infographic

cookingdiff.com

cookingdiff.com