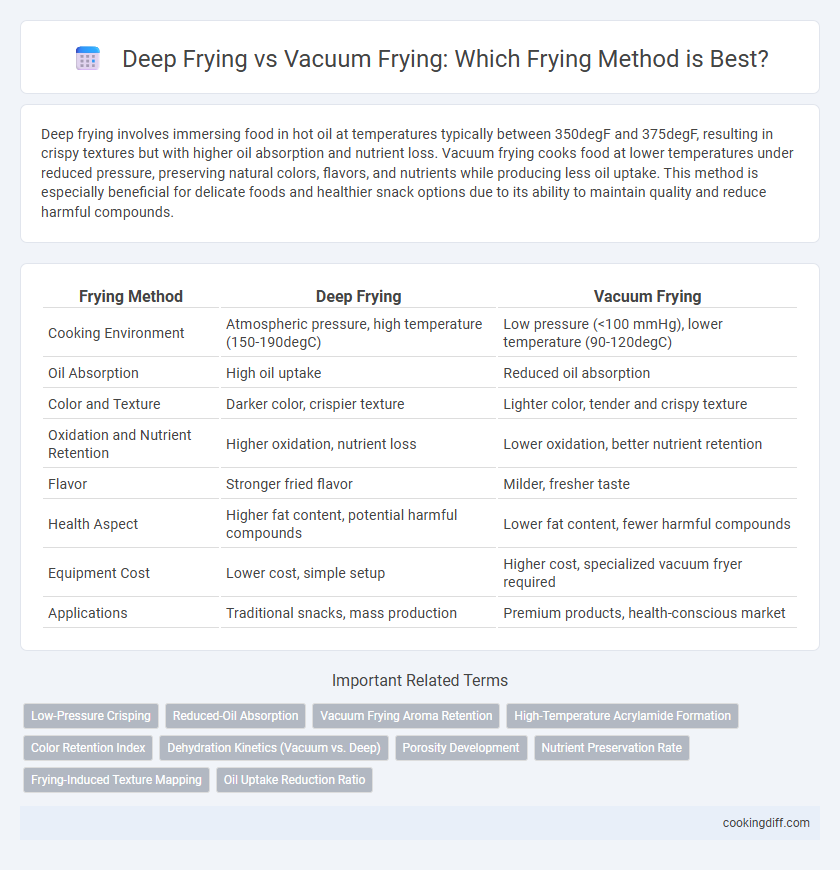

Deep frying involves immersing food in hot oil at temperatures typically between 350degF and 375degF, resulting in crispy textures but with higher oil absorption and nutrient loss. Vacuum frying cooks food at lower temperatures under reduced pressure, preserving natural colors, flavors, and nutrients while producing less oil uptake. This method is especially beneficial for delicate foods and healthier snack options due to its ability to maintain quality and reduce harmful compounds.

Table of Comparison

| Frying Method | Deep Frying | Vacuum Frying |

|---|---|---|

| Cooking Environment | Atmospheric pressure, high temperature (150-190degC) | Low pressure (<100 mmHg), lower temperature (90-120degC) |

| Oil Absorption | High oil uptake | Reduced oil absorption |

| Color and Texture | Darker color, crispier texture | Lighter color, tender and crispy texture |

| Oxidation and Nutrient Retention | Higher oxidation, nutrient loss | Lower oxidation, better nutrient retention |

| Flavor | Stronger fried flavor | Milder, fresher taste |

| Health Aspect | Higher fat content, potential harmful compounds | Lower fat content, fewer harmful compounds |

| Equipment Cost | Lower cost, simple setup | Higher cost, specialized vacuum fryer required |

| Applications | Traditional snacks, mass production | Premium products, health-conscious market |

Introduction to Deep Frying and Vacuum Frying

Deep frying involves immersing food in hot oil, typically between 160-190degC, to achieve a crispy texture and rich flavor. Vacuum frying lowers the boiling point by reducing pressure, allowing frying at temperatures around 85-120degC, which preserves color and nutrients better.

- Deep frying - cooks food quickly by submerging it completely in hot oil, producing a golden, crunchy exterior.

- Vacuum frying - operates under reduced pressure to minimize oil absorption and thermal degradation during frying.

- Health benefits - vacuum frying reduces acrylamide formation and helps retain vitamins compared to traditional deep frying.

Both methods offer unique advantages depending on the food product and desired quality attributes.

How Deep Frying Works: The Traditional Method

Deep frying involves submerging food completely in hot oil, typically heated between 350degF and 375degF, which rapidly cooks and crisps the exterior while sealing in moisture. The high temperature causes the Maillard reaction, creating a flavorful, golden-brown crust essential to traditional frying.

Vacuum frying, in contrast, lowers the pressure to fry food at reduced temperatures, preserving delicate flavors and nutrients that high heat might destroy. This method significantly reduces oil uptake and oxidation compared to conventional deep frying.

The Science Behind Vacuum Frying

Vacuum frying utilizes reduced pressure to lower the boiling point of oil, enabling frying at temperatures typically between 80-120degC, which minimizes oil absorption and preserves natural food color, flavor, and nutrients. This method significantly reduces the formation of harmful compounds like acrylamide compared to conventional deep frying that operates at higher temperatures around 170-190degC. The science behind vacuum frying leverages thermodynamics to produce healthier, crispy products with enhanced sensory qualities and extended shelf life.

Temperature and Oil Usage in Both Methods

How do temperature and oil usage differ between deep frying and vacuum frying methods? Deep frying typically operates at higher temperatures around 170-190degC, leading to faster cooking but increased oil absorption and potential nutrient loss. Vacuum frying occurs at lower temperatures, approximately 90-120degC, which reduces oil uptake and preserves food quality by minimizing oxidation and heat damage.

Impact on Food Texture and Flavor

Deep frying immerses food in hot oil at temperatures between 160degC and 190degC, creating a crispy, golden exterior through rapid moisture evaporation and Maillard reactions. This method often results in a richer flavor and a crunchy texture but can introduce higher oil absorption and potential nutrient loss.

Vacuum frying operates under reduced pressure, allowing frying at lower temperatures around 90degC to 120degC, which slows moisture loss and preserves natural food flavors better. Foods fried via vacuum frying typically exhibit a lighter texture, less oil uptake, and enhanced retention of color and nutrients compared to traditional deep frying.

Nutritional Differences: Oil Absorption and Retention

Deep frying typically results in higher oil absorption, increasing calorie content and fat levels in foods. Vacuum frying reduces oil uptake due to lower frying temperatures and pressure, preserving more nutrients and producing less greasy products.

- Oil Absorption in Deep Frying - Foods immersed at high temperatures absorb more oil, raising fat content significantly.

- Lower Oil Retention in Vacuum Frying - Vacuum frying operates under reduced pressure and temperature, minimizing oil penetration.

- Nutritional Impact - Vacuum frying better preserves vitamins and antioxidants by limiting oil absorption and thermal degradation.

Safety Considerations: Deep Frying vs Vacuum Frying

Deep frying involves cooking food at high temperatures typically between 350degF to 375degF, posing risks of oil splatters and burns. Vacuum frying lowers oil temperature to around 120degF to 160degF, reducing fire hazards and minimizing oil oxidation for safer handling.

Deep frying demands careful monitoring of oil temperature and use of protective equipment to prevent accidents caused by hot oil spills. Vacuum frying operates under reduced pressure, limiting oxygen exposure and decreasing the likelihood of dangerous flare-ups during frying. This method also extends equipment life and enhances operator safety by controlling environmental risks inherent in traditional deep frying.

Equipment Needed for Each Frying Technique

Deep frying requires a sturdy fryer with a temperature control system and a large oil reservoir to fully submerge food items, typically using vegetable or peanut oil at temperatures between 350degF and 375degF. Vacuum frying demands specialized vacuum fryers equipped with sealed chambers that lower atmospheric pressure, enabling frying at lower temperatures around 120degF to 160degF, which helps preserve food nutrients and colors. The equipment for vacuum frying is generally more complex and costly compared to traditional deep fryers, making it suitable for commercial or health-focused applications.

Cost and Efficiency Comparison

| Method | Cost | Efficiency |

|---|---|---|

| Deep Frying | Lower initial investment but higher oil consumption and energy costs due to high temperatures. | Faster cooking times with significant oil absorption, resulting in less product yield efficiency. |

| Vacuum Frying | Higher upfront equipment cost but reduces oil degradation and lowers energy consumption by frying at lower temperatures. | Improves product quality and yield by minimizing oil absorption and oxidation, enhancing overall process efficiency. |

Related Important Terms

Low-Pressure Crisping

Vacuum frying uses low-pressure conditions to lower the boiling point of oil, resulting in less oil absorption and preserving the natural color and nutrients of food. This low-pressure crisping method offers a healthier alternative to traditional deep frying by reducing acrylamide formation and maintaining a crisp texture.

Reduced-Oil Absorption

Deep frying typically results in higher oil absorption due to the food being submerged in hot oil at temperatures around 160-190degC, increasing fat content and calories. Vacuum frying operates under reduced pressure, lowering the boiling point of oil and moisture, which significantly reduces oil absorption while preserving texture and nutrients.

Vacuum Frying Aroma Retention

Vacuum frying preserves the natural aroma of food by frying at lower temperatures under reduced pressure, minimizing volatile compound loss compared to traditional deep frying. This method enhances flavor retention and ensures a more intense sensory experience in fried products.

High-Temperature Acrylamide Formation

Deep frying at high temperatures typically causes significant acrylamide formation due to the Maillard reaction between reducing sugars and amino acids, posing health risks in fried foods. Vacuum frying reduces acrylamide formation by lowering the boiling point of water, allowing frying at lower temperatures and minimizing heat-induced chemical reactions.

Color Retention Index

Vacuum frying significantly improves the Color Retention Index by reducing oxidation and thermal degradation compared to traditional deep frying, resulting in brighter and more visually appealing food products. Deep frying exposes foods to higher oxygen levels and temperatures, causing rapid browning and color loss, whereas vacuum frying operates under low pressure, preserving natural pigments and enhancing color stability.

Dehydration Kinetics (Vacuum vs. Deep)

Vacuum frying lowers the boiling point of water, accelerating dehydration kinetics and preserving product quality by reducing thermal degradation compared to conventional deep frying, which operates at higher temperatures and causes faster moisture loss. The controlled low-pressure environment in vacuum frying enhances moisture diffusion rates while minimizing oil uptake, resulting in improved texture and nutritional retention relative to the rapid dehydration and higher oil absorption typical in deep frying.

Porosity Development

Deep frying promotes rapid moisture evaporation, resulting in significant porosity development and a crispy texture due to the expansion of vapor bubbles within the food matrix. Vacuum frying reduces boiling point and moisture loss, producing lower porosity and a denser, less crispy product by minimizing bubble formation during frying.

Nutrient Preservation Rate

Deep frying exposes food to high temperatures around 170-190degC, leading to significant nutrient degradation, especially vitamins and antioxidants. Vacuum frying operates under reduced pressure at lower temperatures (typically 80-120degC), substantially enhancing nutrient preservation rates by minimizing oxidation and thermal damage.

Frying-Induced Texture Mapping

Deep frying creates a crispy, crunchy texture through rapid oil absorption and high temperatures, resulting in a porous structure with distinct surface browning, while vacuum frying preserves natural colors and nutrients by frying at lower temperatures under reduced pressure, producing a less brittle but uniformly textured product. Frying-induced texture mapping reveals that vacuum frying minimizes cellular collapse and oil uptake, enhancing product quality and shelf-life compared to conventional deep frying.

Deep frying vs Vacuum frying for method. Infographic

cookingdiff.com

cookingdiff.com