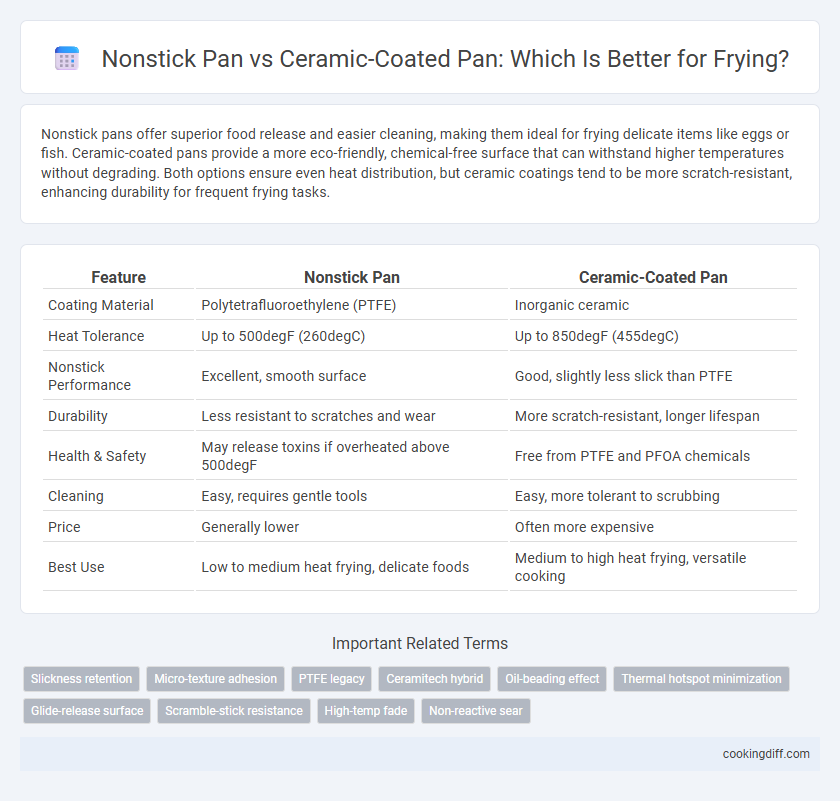

Nonstick pans offer superior food release and easier cleaning, making them ideal for frying delicate items like eggs or fish. Ceramic-coated pans provide a more eco-friendly, chemical-free surface that can withstand higher temperatures without degrading. Both options ensure even heat distribution, but ceramic coatings tend to be more scratch-resistant, enhancing durability for frequent frying tasks.

Table of Comparison

| Feature | Nonstick Pan | Ceramic-Coated Pan |

|---|---|---|

| Coating Material | Polytetrafluoroethylene (PTFE) | Inorganic ceramic |

| Heat Tolerance | Up to 500degF (260degC) | Up to 850degF (455degC) |

| Nonstick Performance | Excellent, smooth surface | Good, slightly less slick than PTFE |

| Durability | Less resistant to scratches and wear | More scratch-resistant, longer lifespan |

| Health & Safety | May release toxins if overheated above 500degF | Free from PTFE and PFOA chemicals |

| Cleaning | Easy, requires gentle tools | Easy, more tolerant to scrubbing |

| Price | Generally lower | Often more expensive |

| Best Use | Low to medium heat frying, delicate foods | Medium to high heat frying, versatile cooking |

Introduction to Frying Pans: Nonstick vs Ceramic-Coated

Nonstick pans feature a synthetic coating that prevents food from sticking, making them ideal for frying delicate items like eggs and fish. Ceramic-coated pans use a natural, non-toxic layer that offers a chemical-free alternative with good heat retention and scratch resistance.

Both pan types provide efficient heat distribution, but ceramic-coated pans tend to withstand higher temperatures without releasing harmful fumes. Choosing between nonstick and ceramic-coated frying pans depends on cooking style, durability preferences, and health considerations.

Material Composition and Surface Technologies

| Type of Pan | Material Composition | Surface Technologies |

|---|---|---|

| Nonstick Pan | Typically made of aluminum or stainless steel coated with polytetrafluoroethylene (PTFE) or similar fluoropolymer | PTFE provides a smooth, low-friction surface that prevents food from sticking and allows for easy cleanup |

| Ceramic-Coated Pan | Often constructed from aluminum with a silica-based ceramic coating derived from sand | Ceramic coating offers a hard, heat-resistant surface that is free of PTFE and PFOA, providing natural nonstick properties and increased durability |

Heat Distribution and Cooking Performance

Nonstick pans typically offer superior heat distribution due to their metal bases, ensuring even cooking without hot spots, whereas ceramic-coated pans may heat unevenly if the base material is inferior. Cooking performance in nonstick pans excels with low to medium heat, ideal for delicate foods, while ceramic-coated pans handle higher temperatures better, allowing for more versatile frying techniques.

- Heat distribution - Nonstick pans generally have aluminum bases that promote consistent heat flow across the surface.

- Durability at high heat - Ceramic-coated pans withstand higher temperatures without degrading nonstick properties.

- Cooking versatility - Ceramic-coated pans tolerate searing and frying at higher temperatures better than traditional nonstick pans.

Choosing between nonstick and ceramic-coated pans depends on preferred cooking temperatures and desired frying outcomes.

Nonstick Capabilities: Which Pan Delivers Better Release?

Nonstick pans utilize a PTFE-based coating, offering superior food release and minimal oil requirement for frying. Ceramic-coated pans provide a naturally slick surface but tend to lose their nonstick efficiency faster under high heat.

Nonstick pans consistently deliver better release performance, making them ideal for eggs and delicate foods. Ceramic-coated pans are more environmentally friendly but often require more oil to prevent sticking. Over time, nonstick coatings maintain their slickness longer, enhancing frying results.

Durability and Scratch Resistance

Nonstick pans typically feature a PTFE coating that offers moderate durability but can degrade with frequent use and exposure to high heat. Ceramic-coated pans provide enhanced scratch resistance due to their harder surface, making them more durable under regular frying conditions.

Despite ceramic coatings being more resistant to abrasion, they may lose their nonstick properties faster than traditional nonstick pans. Choosing a ceramic-coated pan ensures better longevity against scratches, while nonstick pans require careful handling to maintain their surface integrity.

Ease of Cleaning and Maintenance

Nonstick pans offer superior ease of cleaning due to their smooth synthetic coatings that prevent food from sticking, requiring minimal effort and often just a quick wipe. Ceramic-coated pans, while also nonstick, may need more careful handling and gentle cleaning to avoid chipping and maintain their effectiveness over time.

- Nonstick pans resist residue buildup - Their PTFE coating allows effortless food release, simplifying cleanup after frying.

- Ceramic-coated pans require gentle washing - Harsh scrubbing can damage the ceramic layer, reducing nonstick performance.

- Durability affects maintenance frequency - Nonstick coatings can degrade faster under abrasive cleaning compared to ceramic alternatives.

Health and Safety Considerations

Nonstick pans often contain PTFE and PFOA, chemicals that can release harmful fumes if overheated above 500degF, posing health risks. Ceramic-coated pans offer a safer alternative by using inorganic materials free from toxic chemicals, which reduces the possibility of toxic emissions during frying. Both pan types require careful temperature control to ensure food safety and avoid degradation of the coating that could affect health.

Compatibility with Different Cooktops

Nonstick pans generally exhibit excellent compatibility with all cooktop types, including gas, electric, and induction, due to their versatile base materials. Ceramic-coated pans may have limitations on induction cooktops unless specifically designed with a magnetic base.

- Nonstick Pans Compatibility - Most nonstick pans feature aluminum or stainless steel bases that work efficiently on gas, electric, and induction cooktops.

- Ceramic-Coated Pans for Induction - Ceramic-coated pans require a magnetic base to be induction compatible, which is not always present in standard models.

- Heat Distribution - Both pan types provide even heat distribution on gas and electric cooktops, but induction requires proper base material for optimal performance.

Price Comparison and Value for Money

Nonstick pans generally come at a lower price point compared to ceramic-coated pans, making them more accessible for budget-conscious buyers. Ceramic-coated pans, while more expensive, offer enhanced durability and are free from potentially harmful chemicals, providing better long-term value. Investing in ceramic-coated pans can lead to savings over time due to their resistance to scratching and longer lifespan in frying applications.

Related Important Terms

Slickness retention

Nonstick pans typically maintain their slickness longer due to advanced PTFE coatings that resist food adhesion and degradation. Ceramic-coated pans may lose slickness faster as their surface can become porous and less smooth with high-heat use and repeated cooking.

Micro-texture adhesion

Nonstick pans feature a smooth micro-texture that minimizes food adhesion, allowing for easy release and less oil usage during frying. Ceramic-coated pans have a slightly rougher surface micro-texture, which offers better durability but can increase food adhesion compared to traditional nonstick coatings.

PTFE legacy

Nonstick pans with PTFE coatings provide superior nonstick performance and excellent heat distribution but raise concerns due to PTFE's potential release of harmful fumes at high temperatures. Ceramic-coated pans offer a safer, eco-friendly alternative with better heat tolerance but generally lack the same durability and slickness as traditional PTFE nonstick surfaces.

Ceramitech hybrid

Ceramitech hybrid pans combine the durability of ceramic-coated surfaces with enhanced nonstick properties, offering superior heat distribution and scratch resistance compared to traditional nonstick pans. These pans enable oil-free frying with quick cleanup, making them an ideal choice for health-conscious cooking and long-lasting performance.

Oil-beading effect

Nonstick pans exhibit a superior oil-beading effect due to their smooth, hydrophobic coatings that cause oil to form distinct droplets, enhancing even heat distribution and reducing sticking during frying. Ceramic-coated pans, while environmentally friendly and free from certain chemicals, often display less pronounced oil-beading, resulting in oil spreading more thinly and potentially affecting frying performance.

Thermal hotspot minimization

Nonstick pans typically feature superior heat distribution technology that minimizes thermal hotspots, ensuring even frying temperatures and reducing the risk of food burning. Ceramic-coated pans offer decent heat retention but may develop uneven heating zones faster, impacting consistent cooking performance during frying.

Glide-release surface

Nonstick pans offer a superior glide-release surface due to their polytetrafluoroethylene (PTFE) coating, ensuring effortless food release and easy cleaning during frying. Ceramic-coated pans provide a natural, toxin-free glide-release surface but may require more careful maintenance to preserve their nonstick properties over time.

Scramble-stick resistance

Nonstick pans typically offer superior scramble-stick resistance due to their fluoropolymer coatings, which create a smoother, non-porous surface that prevents eggs and other ingredients from adhering during frying. Ceramic-coated pans provide moderate stick resistance by using a harder, inorganic layer that is free from PTFE and PFOA, but they often require more oil and careful temperature control to prevent food from sticking while scrambling.

High-temp fade

Nonstick pans often experience high-temp fade when exposed to temperatures above 500degF, resulting in diminished coating effectiveness and potential toxic fume release. Ceramic-coated pans maintain their appearance and nonstick properties better at high temperatures up to 600degF, making them more durable for intense frying tasks.

Nonstick pan vs ceramic-coated pan for frying. Infographic

cookingdiff.com

cookingdiff.com