Microwave defrosting uses timed intervals to gently thaw food by emitting controlled microwave energy, which can sometimes lead to uneven thawing or partially cooked edges. Sensor defrost, on the other hand, employs built-in moisture and temperature sensors to automatically adjust the defrosting time, ensuring more accurate and uniform thawing without overcooking. Choosing sensor defrost enhances convenience and preserves food texture by adapting to the specific weight and moisture levels of the food.

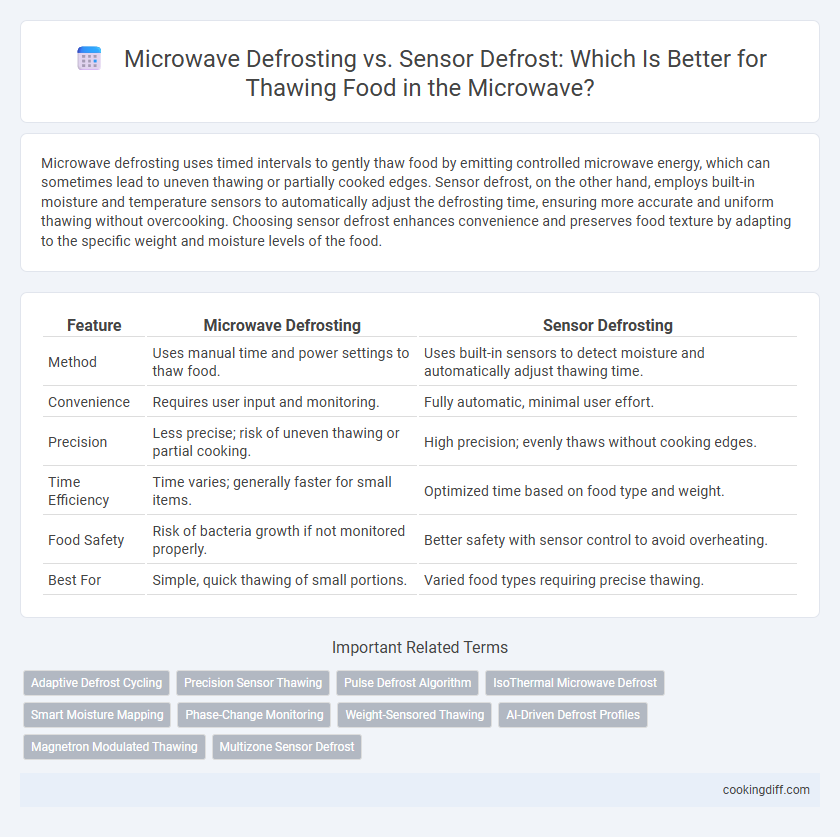

Table of Comparison

| Feature | Microwave Defrosting | Sensor Defrosting |

|---|---|---|

| Method | Uses manual time and power settings to thaw food. | Uses built-in sensors to detect moisture and automatically adjust thawing time. |

| Convenience | Requires user input and monitoring. | Fully automatic, minimal user effort. |

| Precision | Less precise; risk of uneven thawing or partial cooking. | High precision; evenly thaws without cooking edges. |

| Time Efficiency | Time varies; generally faster for small items. | Optimized time based on food type and weight. |

| Food Safety | Risk of bacteria growth if not monitored properly. | Better safety with sensor control to avoid overheating. |

| Best For | Simple, quick thawing of small portions. | Varied food types requiring precise thawing. |

Introduction to Microwave and Sensor Defrosting

Microwave defrosting uses timed power levels to thaw frozen food evenly by softening outer layers while preventing cooking. Sensor defrosting employs built-in moisture and temperature sensors to automatically adjust defrosting time based on the food's condition.

Microwave defrosting operates on preset defrost cycles requiring manual time and power adjustments. Sensor defrosting offers greater precision by detecting heat and moisture changes, reducing the risk of uneven thawing or partial cooking.

How Traditional Microwave Defrosting Works

Traditional microwave defrosting operates by applying low power levels to melt ice crystals in frozen food evenly, avoiding cooking the edges. This method requires manual time and power adjustments for different food types and sizes to ensure proper thawing without partial cooking.

- Fixed Power Levels - Typically uses a preset, reduced power setting to gently thaw food without cooking it.

- Manual Time Setting - Users set the defrosting time based on food weight and type, requiring attention to avoid uneven thawing.

- Intermittent Heating - Microwave cycles on and off to prevent cooking, allowing heat to distribute gradually throughout the frozen item.

Understanding Sensor Defrost Technology

Sensor defrost technology uses built-in moisture and temperature sensors to accurately detect the thawing progress of food, preventing overcooking and uneven heating. This method adjusts power levels and defrosting time automatically, optimizing the thawing process compared to traditional microwave defrosting.

Unlike manual defrost settings that rely on preset times, sensor defrost adapts in real-time, providing consistent and safe thawing for various types of frozen foods. It enhances convenience by eliminating guesswork and reducing the risk of partially frozen or overheated spots within the food.

Accuracy in Thawing: Manual vs Sensor Methods

Manual microwave defrosting relies on preset time and power settings, often leading to uneven thawing and partially cooked edges due to inconsistent heat distribution. Sensor defrosting uses embedded sensors to detect moisture and temperature changes, providing more precise control and reducing the risk of overcooking or under-thawing. This sensor-driven accuracy ensures food is thawed evenly, preserving texture and safety more effectively than traditional manual methods.

Speed Comparison: Which Is Faster?

Microwave defrosting typically offers faster thawing by applying consistent high power, which rapidly heats food. Sensor defrost adjusts power and time based on moisture and temperature, resulting in a more controlled but often slower thawing process.

- Microwave Defrosting Speed - Uses fixed power settings to quickly raise food temperature, reducing overall defrost time.

- Sensor Defrost Efficiency - Employs sensors to prevent overcooking but extends thawing time for even heat distribution.

- Speed Comparison - Microwave defrost generally outpaces sensor defrost by several minutes on average, especially for smaller food portions.

Evenness of Defrost: Avoiding Hot and Cold Spots

How does microwave defrosting compare to sensor defrost in terms of evenness of defrost to avoid hot and cold spots? Microwave defrosting typically uses fixed power levels and time settings, which can lead to uneven thawing with some areas partially cooked while others remain frozen. Sensor defrost technology adjusts the power and timing based on moisture and temperature sensors, promoting more uniform thawing and minimizing hot and cold spots in food.

User Experience and Ease of Operation

Microwave defrosting requires manual time and power adjustments, which can lead to uneven thawing and a trial-and-error user experience. Sensor defrost uses built-in moisture and temperature sensors to automatically optimize the thawing process, enhancing ease of operation and consistent results.

- Manual Control - Microwave defrost relies on user input for time and power, demanding more attention and experience.

- Automatic Adjustment - Sensor defrost detects food conditions and adjusts settings in real-time for precise thawing.

- User Convenience - Sensor defrost reduces the risk of over or under-thawing, making it simpler for all skill levels.

Sensor defrost offers a more user-friendly thawing experience by minimizing guesswork and optimizing convenience.

Energy Efficiency in Defrost Modes

Microwave defrosting typically uses a fixed power level and time, which can lead to uneven thawing and increased energy consumption. Sensor defrost technology adjusts power and duration based on moisture and temperature, optimizing energy use during the thawing process.

Sensor defrost enhances energy efficiency by preventing over-processing and reducing wasted power, making it more eco-friendly compared to traditional microwave defrost modes. Precise control helps maintain consistent thawing results, minimizing the need for repeated cycles. This targeted approach can lower overall electricity usage while ensuring food safety and quality during defrosting.

Suitability for Different Food Types

| Defrosting Method | Food Type Suitability | Key Considerations |

|---|---|---|

| Microwave Defrosting | Best for uniform, small cuts of meat, poultry, and seafood. | Manual time and power settings may lead to uneven thawing or partial cooking if not carefully monitored. |

| Sensor Defrost | Ideal for a variety of frozen foods including complex shapes and mixed food types. | Utilizes built-in humidity and temperature sensors for precise thawing, reducing risk of overcooking or uneven thawing. |

Related Important Terms

Adaptive Defrost Cycling

Microwave defrosting uses preset time and power levels to thaw food, while sensor defrost leverages moisture and temperature sensors to adjust defrosting time dynamically, enhancing thaw uniformity and preventing partial cooking. Adaptive defrost cycling in sensor defrost optimizes energy use and maintains food quality by automatically modifying defrost intervals based on real-time feedback from the food's condition.

Precision Sensor Thawing

Precision Sensor Thawing uses advanced sensors to detect moisture and temperature levels within food, enabling uniform defrosting without partial cooking or drying. This method offers superior accuracy compared to traditional microwave defrosting, reducing thawing time and preserving texture and flavor.

Pulse Defrost Algorithm

The Pulse Defrost Algorithm in microwave defrosting uses intermittent bursts of energy to evenly thaw food without partially cooking it, enhancing texture preservation compared to traditional Sensor Defrost methods that rely on moisture or temperature sensors to detect thaw progress. This algorithm optimizes thawing efficiency by reducing cold spots and minimizing nutrient loss, making it superior for delicate or unevenly shaped foods.

IsoThermal Microwave Defrost

IsoThermal Microwave Defrost maintains consistent temperature levels during thawing, minimizing partial cooking and ensuring even defrosting compared to traditional sensor defrost methods that rely on humidity or temperature sensors and may cause uneven thawing. This technology optimizes microwave energy distribution by combining precise power control with continuous monitoring, ideal for safely preserving food texture and quality.

Smart Moisture Mapping

Microwave defrosting uses a timed power cycle to gradually thaw food but may unevenly defrost, risking partial cooking or cold spots. Sensor defrost with Smart Moisture Mapping technology detects moisture levels to adjust power and time dynamically, ensuring uniform thawing while preserving texture and flavor.

Phase-Change Monitoring

Microwave defrosting relies on timed power levels, often resulting in uneven thawing with partially warm edges and frozen centers, while sensor defrost uses phase-change monitoring to detect temperature shifts during thawing, optimizing heat distribution and preventing overcooking. Phase-change monitoring enhances precision by adjusting microwave energy in real time based on the transition from solid to liquid state, ensuring consistent thawing performance.

Weight-Sensored Thawing

Weight-sensored thawing in microwave defrosting uses precise weight measurements to calculate optimal defrosting time and power, ensuring even thawing and reducing the risk of partially cooked edges. Unlike standard sensor defrost methods that rely on humidity or temperature, weight-based defrosting provides more accurate results for various food types and portions.

AI-Driven Defrost Profiles

AI-driven defrost profiles in microwaving optimize thawing by analyzing the weight, type, and temperature of frozen food to prevent uneven defrosting and partial cooking. Sensor defrost systems use moisture and temperature sensors but lack the adaptive learning capabilities of AI, resulting in less precise defrost cycles compared to AI-driven technology.

Magnetron Modulated Thawing

Microwave defrosting uses a constant power level that risks uneven thawing and partial cooking, whereas sensor defrost optimizes thawing by detecting moisture and adjusting power accordingly. Magnetron modulated thawing enhances sensor defrost by dynamically adjusting microwave energy levels, ensuring uniform thawing and minimizing heat damage to food texture.

Microwave Defrosting vs Sensor Defrost for thawing Infographic

cookingdiff.com

cookingdiff.com