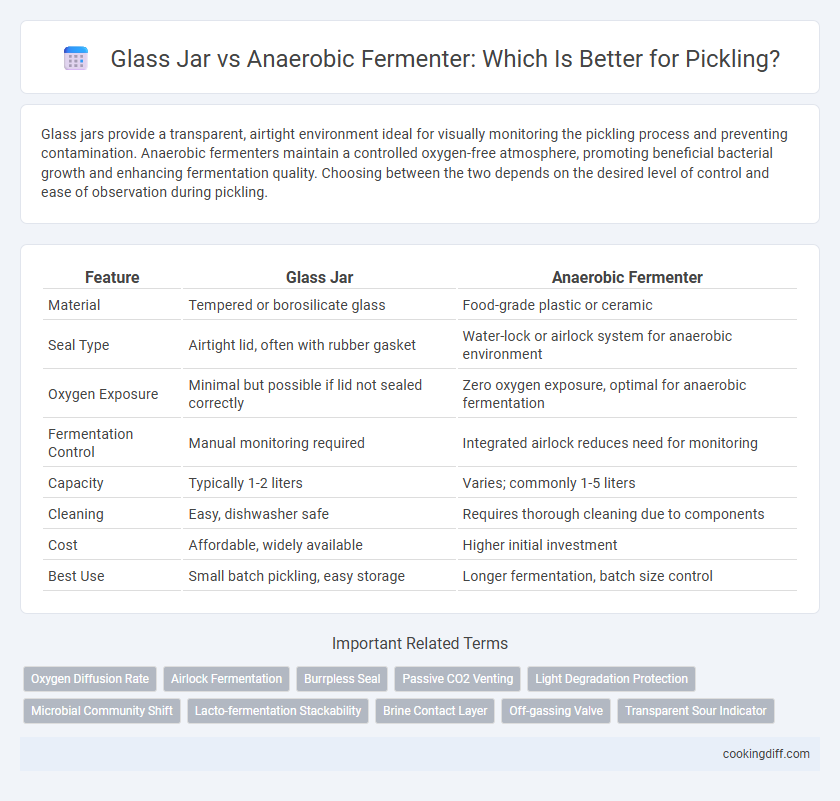

Glass jars provide a transparent, airtight environment ideal for visually monitoring the pickling process and preventing contamination. Anaerobic fermenters maintain a controlled oxygen-free atmosphere, promoting beneficial bacterial growth and enhancing fermentation quality. Choosing between the two depends on the desired level of control and ease of observation during pickling.

Table of Comparison

| Feature | Glass Jar | Anaerobic Fermenter |

|---|---|---|

| Material | Tempered or borosilicate glass | Food-grade plastic or ceramic |

| Seal Type | Airtight lid, often with rubber gasket | Water-lock or airlock system for anaerobic environment |

| Oxygen Exposure | Minimal but possible if lid not sealed correctly | Zero oxygen exposure, optimal for anaerobic fermentation |

| Fermentation Control | Manual monitoring required | Integrated airlock reduces need for monitoring |

| Capacity | Typically 1-2 liters | Varies; commonly 1-5 liters |

| Cleaning | Easy, dishwasher safe | Requires thorough cleaning due to components |

| Cost | Affordable, widely available | Higher initial investment |

| Best Use | Small batch pickling, easy storage | Longer fermentation, batch size control |

Introduction: Glass Jars vs Anaerobic Fermenters in Pickling

Glass jars are a traditional choice for pickling, offering a clear view of contents and ease of use for small batches. Their airtight seals help preserve the flavor and texture of pickled vegetables by minimizing oxygen exposure.

Anaerobic fermenters provide a controlled environment that encourages natural fermentation processes by eliminating oxygen. This method enhances probiotic development and supports consistent, large-scale pickling results.

Traditional Pickling: The Role of Glass Jars

Glass jars are the cornerstone of traditional pickling, offering a non-reactive, transparent container that allows for easy monitoring of the fermentation process. Their airtight sealing capabilities create an ideal anaerobic environment crucial for preserving the texture and flavor of pickled vegetables. Unlike specialized anaerobic fermenters, glass jars are widely accessible and versatile, making them a preferred choice for classic, small-batch pickling enthusiasts.

Modern Advances: Understanding Anaerobic Fermenters

Modern anaerobic fermenters offer precise oxygen control critical for consistent pickling, reducing spoilage compared to traditional glass jars. These fermenters maintain an ideal environment that accelerates fermentation by promoting beneficial bacteria growth while inhibiting harmful microbes.

- Oxygen Control - Anaerobic fermenters create a sealed environment that eliminates oxygen exposure, essential for authentic lacto-fermentation.

- Consistency - Automated systems in fermenters regulate temperature and pressure, ensuring uniform pickling results every batch.

- Reduced Contamination - The closed system minimizes risk of mold and yeast contamination common in open glass jar methods.

Oxygen Exposure: Impact on Pickling Fermentation

Glass jars allow limited oxygen exposure during pickling, which can lead to slower fermentation and potential mold growth on the surface. Anaerobic fermenters create an oxygen-free environment, promoting beneficial lactic acid bacteria growth essential for consistent and efficient fermentation. Controlling oxygen exposure is critical to prevent spoilage and achieve the desired acidity and flavor in pickled products.

Flavor Profiles: Differences Between Jar and Fermenter Methods

| Glass Jar | Provides controlled oxygen exposure which enhances brighter, tangy flavor profiles due to slower fermentation and limited anaerobic conditions. |

| Anaerobic Fermenter | Ensures complete exclusion of oxygen, promoting consistent, complex umami and probiotic-rich flavors by fostering ideal anaerobic microbial activity throughout fermentation. |

| Flavor Development | Glass jars typically result in crisper, sharper notes; anaerobic fermenters produce deeper, more robust fermented flavors favored in traditional pickling cultures. |

Safety and Contamination Risks in Both Systems

Glass jars offer a non-reactive environment reducing the risk of chemical contamination during pickling, but their exposure to air increases the potential for mold growth if not sealed properly. Anaerobic fermenters create an oxygen-free environment that minimizes spoilage and harmful bacterial growth, enhancing safety in the fermentation process.

In glass jars, improper sealing or contaminated utensils can introduce harmful pathogens, posing safety risks. Anaerobic fermenters use airlocks to prevent oxygen entry, which significantly reduces contamination from unwanted aerobic microorganisms. Both systems require strict hygiene and monitoring to ensure a safe and successful pickling outcome.

Ease of Use and Maintenance for Home Picklers

Which option is easier for home picklers to use and maintain: glass jars or anaerobic fermenters? Glass jars are widely favored due to their simplicity, easy cleaning, and availability in various sizes for small batches. Anaerobic fermenters require more care to maintain airtight conditions and may involve additional parts that need regular cleaning to prevent mold growth.

Cost Comparison: Glass Jars vs Fermenters

Glass jars typically have a lower initial cost per unit compared to anaerobic fermenters but might require more frequent replacement due to fragility. Anaerobic fermenters involve a higher upfront investment but offer durability and reusable features that can reduce long-term expenses.

- Glass Jar Cost - Glass jars usually cost between $1 to $5 each depending on size and quality, making them affordable for small-scale pickling.

- Anaerobic Fermenter Investment - Anaerobic fermenters can range from $30 to $100 or more, reflecting the specialized design for oxygen-free fermentation.

- Long-Term Expense - While glass jars may break and need replacement, fermenters provide reusable, durable options that potentially save money over multiple pickling cycles.

Fermentation Time and Batch Consistency

Glass jars often require longer fermentation times due to less controlled environments, while anaerobic fermenters provide a sealed setting that speeds up the process and enhances batch consistency. Anaerobic fermenters maintain consistent oxygen levels and temperature, leading to more reliable and repeatable fermentation results compared to traditional glass jars.

- Fermentation Time - Anaerobic fermenters typically reduce fermentation time by creating optimal anaerobic conditions, accelerating microbial activity.

- Batch Consistency - Sealed anaerobic fermenters minimize contamination and oxygen exposure, resulting in uniform flavor and texture across batches.

- Monitoring - Glass jars require frequent manual checks and adjustments, whereas anaerobic fermenters allow controlled, stable fermentation environments.

Choosing an anaerobic fermenter improves efficiency and predictability in pickling compared to using glass jars.

Related Important Terms

Oxygen Diffusion Rate

Glass jars provide a low oxygen diffusion rate, creating an optimal anaerobic environment essential for effective pickling and fermentation. Anaerobic fermenters are specifically designed to further minimize oxygen exposure, ensuring consistent fermentation results by maintaining near-zero oxygen levels.

Airlock Fermentation

Glass jars provide a simple, accessible option for pickling but lack the airtight environment necessary for true anaerobic fermentation, which is critical for preventing mold and promoting lactic acid bacteria growth. Anaerobic fermenters with built-in airlocks maintain a controlled oxygen-free environment, allowing carbon dioxide to escape while stopping oxygen entry, thereby enhancing flavor development and ensuring consistent fermentation results.

Burrpless Seal

Glass jars with burrpless seals offer an airtight environment crucial for pickling, preventing oxygen exposure and contamination that could spoil anaerobic fermentation. Compared to traditional anaerobic fermenters, these jars provide a reliable seal that maintains the ideal anaerobic conditions, ensuring consistent and safe fermentation of vegetables.

Passive CO2 Venting

Glass jars rely on passive CO2 venting through loosely sealed lids or specially designed airlocks to prevent pressure buildup during pickling. Anaerobic fermenters typically feature built-in airlocks that allow CO2 to escape automatically while maintaining an oxygen-free environment, enhancing fermentation control and reducing spoilage risk.

Light Degradation Protection

Glass jars provide moderate protection against light degradation but may allow some UV rays to penetrate, potentially affecting the quality and color of pickled products. Anaerobic fermenters often incorporate opaque or UV-resistant materials, offering superior protection against light-induced spoilage and preserving the integrity of the fermentation process.

Microbial Community Shift

Glass jars create an oxygen-limited environment that encourages lactic acid bacteria, resulting in a stable microbial community beneficial for pickling. Anaerobic fermenters provide a fully oxygen-free atmosphere, promoting a more diverse and accelerated microbial community shift that enhances fermentation speed and flavor complexity.

Lacto-fermentation Stackability

Glass jars offer excellent visibility and airtight seals ideal for lacto-fermentation, but their rigid shape limits efficient stackability during fermentation. Anaerobic fermenters are designed with space-saving, stackable features that optimize oxygen exclusion and maintain consistent fermentation conditions, enhancing scalability for bulk lacto-fermentation projects.

Brine Contact Layer

Glass jars provide a non-reactive, inert brine contact layer ideal for maintaining pure flavors and preventing contamination during pickling. Anaerobic fermenters typically use food-grade plastic or silicone seals that create an oxygen-free environment but may interact slightly with the brine, potentially affecting fermentation quality.

Off-gassing Valve

Glass jars lack an off-gassing valve, requiring manual release of carbon dioxide during fermentation to prevent pressure buildup, whereas anaerobic fermenters feature built-in off-gassing valves that automatically release gas while maintaining an oxygen-free environment, reducing the risk of spoilage and ensuring consistent fermentation results. Off-gassing valves optimize fermentation by managing CO2 expulsion efficiently, making anaerobic fermenters superior for controlled pickling processes.

Glass Jar vs Anaerobic Fermenter for pickling. Infographic

cookingdiff.com

cookingdiff.com