Plastic containers offer affordability and lightweight convenience for pickling, but may retain odors and stains over time, impacting flavor and hygiene. Vacuum fermentation jars create an airtight environment crucial for consistent fermentation, reducing oxidation and spoilage risks, which enhances the quality and safety of pickled products. Choosing vacuum jars optimizes fermentation control and preserves taste more effectively than traditional plastic containers.

Table of Comparison

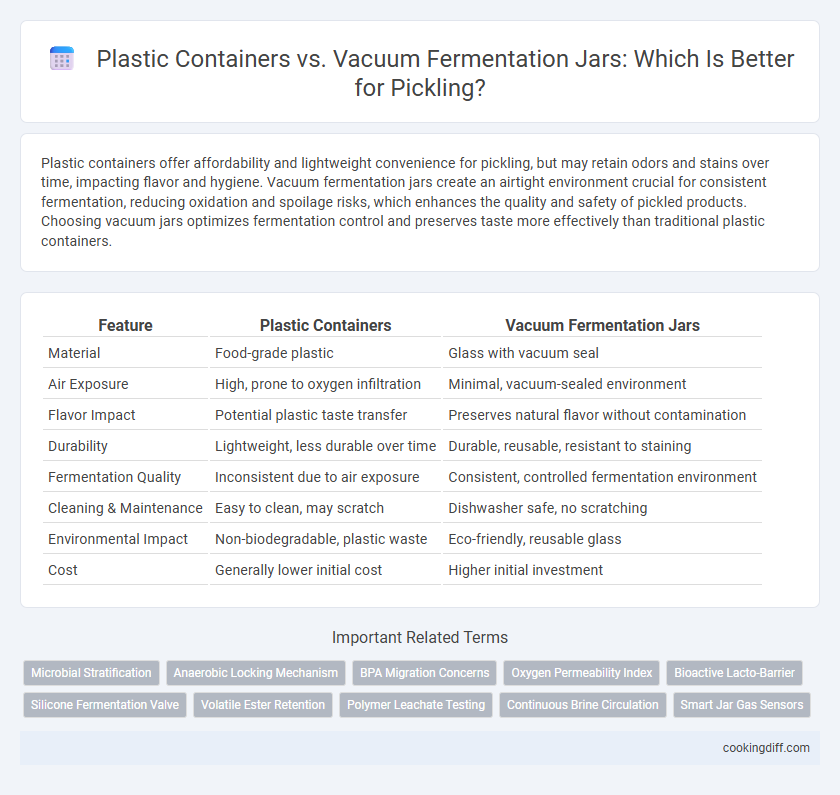

| Feature | Plastic Containers | Vacuum Fermentation Jars |

|---|---|---|

| Material | Food-grade plastic | Glass with vacuum seal |

| Air Exposure | High, prone to oxygen infiltration | Minimal, vacuum-sealed environment |

| Flavor Impact | Potential plastic taste transfer | Preserves natural flavor without contamination |

| Durability | Lightweight, less durable over time | Durable, reusable, resistant to staining |

| Fermentation Quality | Inconsistent due to air exposure | Consistent, controlled fermentation environment |

| Cleaning & Maintenance | Easy to clean, may scratch | Dishwasher safe, no scratching |

| Environmental Impact | Non-biodegradable, plastic waste | Eco-friendly, reusable glass |

| Cost | Generally lower initial cost | Higher initial investment |

Introduction to Pickling: Methods and Materials

Pickling preserves food through fermentation or vinegar brining, requiring airtight storage to maintain flavor and safety. The choice between plastic containers and vacuum fermentation jars significantly impacts the fermentation environment and outcome.

- Plastic Containers - Lightweight and affordable, but prone to scratches that harbor bacteria and may leach chemicals into acidic pickles.

- Vacuum Fermentation Jars - Designed to remove oxygen, creating an ideal anaerobic environment for consistent fermentation and enhanced flavor development.

- Material Durability - Glass vacuum jars resist staining and odors better than plastic, ensuring long-term usability and food safety.

Selecting vacuum fermentation jars enhances pickling quality by optimizing fermentation conditions and reducing contamination risks.

Plastic Containers: Pros and Cons in Pickling

| Plastic Containers Pros | Lightweight and durable, plastic containers are less prone to breakage compared to glass jars, making them ideal for larger batch pickling and easy transportation. |

| Plastic Containers Cons | They may absorb odors and stains from fermented foods, and some plastics can leach chemicals when exposed to acidic environments during long-term fermentation. |

| Comparison to Vacuum Fermentation Jars | Plastic containers lack the airtight vacuum seal provided by specialized fermentation jars, potentially leading to less controlled fermentation and shorter shelf life of pickled products. |

Vacuum Fermentation Jars: Key Features and Benefits

Vacuum fermentation jars create an oxygen-free environment that enhances the pickling process by preventing mold growth and encouraging beneficial anaerobic bacteria. These jars typically include a one-way airlock valve, allowing gases to escape without letting air in, preserving the flavor and texture of fermented vegetables.

Made from durable glass or BPA-free materials, vacuum fermentation jars ensure safe, non-reactive storage for extended fermentation periods. Their airtight seal reduces oxidation risks, resulting in crispier, tangier pickled products compared to traditional plastic containers.

Safety Considerations: Plastic Containers vs. Vacuum Jars

Are plastic containers or vacuum fermentation jars safer for pickling? Vacuum fermentation jars are typically made from glass, which is non-reactive and reduces the risk of chemical leaching into food, preserving flavor and safety. Plastic containers may release harmful substances over time, especially when exposed to acidic environments, making vacuum jars a safer choice for long-term fermentation.

Flavor Outcomes: Influences of Container Choice

Plastic containers often absorb and retain odors, which can subtly alter the flavor profile of pickled products during fermentation. Vacuum fermentation jars create an oxygen-free environment that promotes anaerobic fermentation, resulting in more consistent, tangy flavors and enhanced preservation of natural aromatics. The choice of container directly influences microbial activity and flavor complexity, with vacuum jars generally producing superior taste outcomes compared to plastic alternatives.

Fermentation Control: Managing Environment in Both Options

Plastic containers for pickling offer flexibility in size and affordability but may lack precise oxygen control, potentially affecting fermentation consistency. Vacuum fermentation jars create a sealed environment that actively reduces oxygen exposure, enhancing anaerobic conditions crucial for optimal microbial activity. Both options require monitoring temperature and cleanliness to manage fermentation effectively, yet vacuum jars provide improved control over air pressure and contamination risk.

Durability and Reusability: Long-Term Use Comparison

Plastic containers for pickling offer lightweight and affordable options but often lack the durability needed for long-term use, as they can warp or stain over time. Vacuum fermentation jars, typically made from glass with airtight seals, provide superior resistance to wear and chemical interactions, ensuring consistent quality in extended fermentation processes.

Reusability favors vacuum fermentation jars due to their robust construction and ease of cleaning, making them a sustainable choice for repeated pickling cycles. Plastic containers may degrade after multiple uses, reducing their effectiveness and potentially impacting the safety of the fermented product.

Cost Analysis: Plastic vs. Vacuum Fermentation Jars

Plastic containers for pickling offer a lower upfront cost, typically ranging from $5 to $15, making them accessible for beginners and budget-conscious individuals. Vacuum fermentation jars, with prices between $30 and $60, present a higher initial investment but are designed for long-term durability and improved fermentation control.

While plastic containers may require replacement every 1-2 years due to staining and odor retention, vacuum fermentation jars often last for several years, reducing overall expenses. The airtight seal of vacuum jars enhances fermentation consistency, potentially lowering waste and product loss. Considering both material longevity and fermentation quality, vacuum jars may provide better cost-efficiency over time despite their higher purchase price.

Cleaning and Maintenance: Ease and Hygiene Factors

Plastic containers require frequent thorough cleaning to prevent odor retention and staining, whereas vacuum fermentation jars are easier to sterilize and maintain hygienic conditions due to their glass composition. Vacuum jars also resist absorbing flavors and are dishwasher-safe, enhancing ease of cleaning compared to plastic.

- Odor and Stain Resistance - Glass vacuum jars do not retain odors or stains like plastic containers, ensuring cleaner and fresher pickling results.

- Dishwasher Compatibility - Vacuum fermentation jars are generally dishwasher-safe, simplifying cleaning routines compared to most plastic alternatives.

- Durability and Sterilization - Glass jars withstand high-temperature sterilization better, promoting improved hygiene over plastic containers prone to surface wear.

Related Important Terms

Microbial Stratification

Plastic containers often allow for uneven microbial stratification during pickling due to their less airtight seals and inconsistent oxygen levels, which can lead to variable fermentation results. Vacuum fermentation jars create a stable, anaerobic environment that promotes uniform microbial layering, optimizing the fermentation process and enhancing the development of consistent flavors and textures.

Anaerobic Locking Mechanism

Plastic containers offer a basic seal for pickling but can allow some oxygen exposure, potentially affecting fermentation quality and shelf life. Vacuum fermentation jars feature an anaerobic locking mechanism that creates a near-perfect oxygen-free environment, enhancing microbial activity and ensuring optimal preservation during the pickling process.

BPA Migration Concerns

Plastic containers used for pickling often contain BPA, which can migrate into acidic or salty fermenting foods, posing potential health risks. Vacuum fermentation jars, typically made from glass and free of BPA, provide a safer alternative by preventing chemical leaching during the pickling process.

Oxygen Permeability Index

Plastic containers for pickling exhibit a higher oxygen permeability index compared to vacuum fermentation jars, potentially leading to increased oxidation and spoilage risk. Vacuum fermentation jars minimize oxygen exposure with a near-zero permeability rate, promoting optimal anaerobic fermentation and preserving the quality of pickled products.

Bioactive Lacto-Barrier

Plastic containers often lack a bioactive lacto-barrier, which can compromise the growth of beneficial lactobacilli during pickling, whereas vacuum fermentation jars create a controlled anaerobic environment that enhances lactic acid bacteria activity and preserves the bioactive compounds. Vacuum fermentation jars also reduce oxygen exposure, preventing spoilage and promoting optimal fermentation, making them superior for maintaining the integrity and flavor of fermented pickles.

Silicone Fermentation Valve

Silicone fermentation valves in vacuum fermentation jars provide an airtight seal that effectively controls gas release, preventing oxidation and contamination during pickling, unlike plastic containers which often lack this precise venting feature. This valve technology enhances fermentation consistency and preserves the quality of pickled products by maintaining optimal anaerobic conditions.

Volatile Ester Retention

Vacuum fermentation jars enhance volatile ester retention during pickling by creating an anaerobic environment that minimizes ester evaporation and oxidation, preserving the aromatic complexity of fermented products. In contrast, plastic containers often allow more air exchange, leading to a reduction in volatile esters and diminished flavor intensity.

Polymer Leachate Testing

Polymer leachate testing reveals that certain plastic containers may release harmful substances into brine during pickling, potentially affecting food safety and flavor profiles. Vacuum fermentation jars, often made from glass or food-grade materials with minimal polymer contact, show significantly lower risks of leachate contamination, ideal for preserving the integrity of fermented vegetables.

Continuous Brine Circulation

Vacuum fermentation jars enhance continuous brine circulation by creating a sealed environment that prevents air infiltration and promotes uniform fermentation, whereas plastic containers often rely on manual agitation to maintain brine movement, risking inconsistent flavor development. The constant pressure in vacuum jars ensures active microbial activity, optimizing the pickling process and reducing spoilage compared to traditional plastic containers.

Plastic Containers vs Vacuum Fermentation Jars for pickling. Infographic

cookingdiff.com

cookingdiff.com