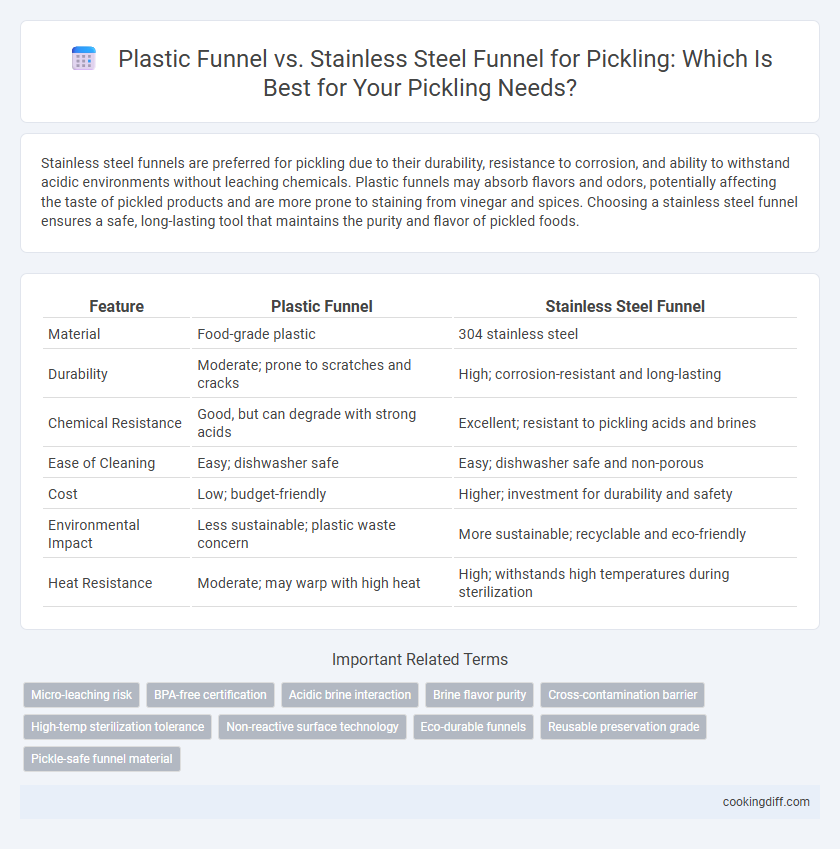

Stainless steel funnels are preferred for pickling due to their durability, resistance to corrosion, and ability to withstand acidic environments without leaching chemicals. Plastic funnels may absorb flavors and odors, potentially affecting the taste of pickled products and are more prone to staining from vinegar and spices. Choosing a stainless steel funnel ensures a safe, long-lasting tool that maintains the purity and flavor of pickled foods.

Table of Comparison

| Feature | Plastic Funnel | Stainless Steel Funnel |

|---|---|---|

| Material | Food-grade plastic | 304 stainless steel |

| Durability | Moderate; prone to scratches and cracks | High; corrosion-resistant and long-lasting |

| Chemical Resistance | Good, but can degrade with strong acids | Excellent; resistant to pickling acids and brines |

| Ease of Cleaning | Easy; dishwasher safe | Easy; dishwasher safe and non-porous |

| Cost | Low; budget-friendly | Higher; investment for durability and safety |

| Environmental Impact | Less sustainable; plastic waste concern | More sustainable; recyclable and eco-friendly |

| Heat Resistance | Moderate; may warp with high heat | High; withstands high temperatures during sterilization |

Introduction to Funnel Materials in Pickling

Plastic funnels are lightweight and resistant to corrosion, making them a popular choice in pickling for their ease of handling and affordability. Stainless steel funnels offer durability, non-reactivity with acidic pickling solutions, and easy sterilization, ensuring long-term use and food safety. Both materials serve distinct purposes, with plastic suited for casual use and stainless steel preferred for heavy-duty or professional pickling processes.

What Is a Plastic Funnel?

A plastic funnel is a lightweight, durable kitchen tool commonly used in pickling to transfer liquids and brine without spills. Made from food-grade, BPA-free plastic, it resists corrosion from acidic substances found in pickling solutions.

Plastic funnels are also affordable and easy to clean, making them a practical choice for home picklers. Their flexibility allows for easy storage, but they may retain odors or stains over time compared to stainless steel alternatives.

What Is a Stainless Steel Funnel?

A stainless steel funnel is a durable kitchen tool made from corrosion-resistant metal, ideal for transferring liquids or fine ingredients during pickling. It maintains its integrity when exposed to acidic substances, unlike some plastic alternatives.

- Durability - Stainless steel funnels resist dents and scratches, ensuring long-term use without degradation.

- Non-reactive Surface - They do not react with acidic foods like vinegar, preventing contamination or off-flavors in pickled products.

- Ease of Cleaning - Stainless steel is easy to sanitize, reducing the risk of bacterial build-up and ensuring food safety in pickling processes.

Durability: Plastic vs. Stainless Steel Funnels

Stainless steel funnels offer superior durability compared to plastic funnels, resisting cracking and warping over time. Plastic funnels may degrade or become brittle when exposed to strong pickling acids or prolonged use, reducing their lifespan.

- Stainless steel durability - Highly resistant to corrosion and physical damage, ideal for repeated pickling tasks.

- Plastic funnel lifespan - Prone to wear and potential chemical reactions with acidic pickling ingredients.

- Material integrity - Stainless steel maintains structural integrity under heat and acidic conditions, whereas plastic may weaken.

Chemical Safety in Pickling: Material Concerns

Plastic funnels may release harmful chemicals like BPA or phthalates during pickling due to their interaction with acidic ingredients, posing potential health risks. Stainless steel funnels, made from non-reactive materials, ensure chemical safety by preventing contamination and preserving the integrity of pickled products.

Choosing a stainless steel funnel reduces the risk of chemical leaching, which can alter the taste and safety of pickled goods. Plastic funnels often degrade over time when exposed to vinegar and spices, increasing the chance of harmful substances entering the food. For optimal chemical safety in pickling, stainless steel funnels provide durability and reliable non-reactivity essential for preserving food quality.

Ease of Cleaning and Maintenance

Plastic funnels used for pickling are lightweight and less prone to staining but can retain odors and may develop cracks over time, complicating thorough cleaning. Their smooth surface allows for quick rinsing, but harsh scrubbers can damage the material, making maintenance essential to prevent bacterial buildup.

Stainless steel funnels offer superior durability and resist staining, making them easier to sanitize after pickling processes involving acidic ingredients. Their non-porous surface withstands rigorous cleaning methods and dishwasher cycles, ensuring long-term hygiene with minimal upkeep.

Impact on Flavor and Food Quality

Plastic funnels may absorb flavors or odors over time, potentially altering the taste of pickled foods. Stainless steel funnels provide a non-porous surface that maintains the original flavor and quality of pickled items.

- Flavor Retention - Stainless steel resists flavor absorption, preventing contamination of pickling brine.

- Durability - Stainless steel funnels withstand acidic environments better, ensuring consistent food quality.

- Hygiene - Non-reactive surfaces of stainless steel reduce bacterial buildup impacting flavor safety.

Choosing stainless steel funnels helps preserve the authentic flavor and enhances the overall quality of pickled foods.

Cost Comparison: Plastic vs. Stainless Steel

| Funnel Type | Initial Cost | Durability | Long-Term Value |

|---|---|---|---|

| Plastic Funnel | Lower upfront cost, typically $3-$8 | Prone to stains and cracks over time due to acidic pickling ingredients | Less cost-effective for frequent use due to wear and potential replacement needs |

| Stainless Steel Funnel | Higher initial investment, averaging $15-$30 | Resistant to corrosion, acid damage, and stains, offering extended longevity | Cost-efficient over long term as it reduces replacement frequency and maintains hygiene |

Environmental Considerations and Sustainability

Stainless steel funnels offer superior durability and are fully recyclable, reducing long-term environmental impact compared to plastic funnels that often contribute to landfill waste. Plastic funnels can leach harmful chemicals over time and are less likely to be recycled, posing significant sustainability challenges. Choosing stainless steel supports eco-friendly pickling practices by minimizing plastic pollution and promoting a circular economy.

Related Important Terms

Micro-leaching risk

Plastic funnels used in pickling reduce the risk of micro-leaching harmful metals compared to stainless steel funnels, which can release trace amounts of nickel and chromium into acidic pickling solutions. Choosing food-grade, BPA-free plastic funnels ensures safer preservation by minimizing chemical contamination and maintaining the integrity of pickled foods.

BPA-free certification

Stainless steel funnels are preferred for pickling due to their BPA-free certification, ensuring no harmful chemicals leach into acidic mixtures, unlike many plastic funnels that may contain BPA. Choosing BPA-free stainless steel funnels guarantees food safety and maintains the purity of pickling ingredients.

Acidic brine interaction

Stainless steel funnels offer superior resistance to acidic brine used in pickling, preventing corrosion and metal leaching that can contaminate the food. Plastic funnels may absorb acidic liquids and degrade over time, posing a risk of chemical interaction and flavor alteration in the pickled products.

Brine flavor purity

Stainless steel funnels preserve brine flavor purity during pickling by preventing chemical reactions and imparting no metallic taste, unlike plastic funnels which may leach compounds that alter the brine's natural flavor. Choosing a stainless steel funnel ensures a cleaner, more authentic pickling process and enhances the overall quality of the preserved product.

Cross-contamination barrier

Stainless steel funnels provide a superior cross-contamination barrier for pickling due to their non-porous, corrosion-resistant surface that resists bacterial growth and chemical leaching. Plastic funnels, while lightweight and affordable, are prone to micro-scratches and absorb odors or residues, increasing the risk of cross-contamination in acidic pickling processes.

High-temp sterilization tolerance

Stainless steel funnels offer superior high-temperature sterilization tolerance compared to plastic funnels, making them ideal for repeated use in pickling processes that require boiling water or steam sterilization. Plastic funnels often degrade or warp under such heat, compromising hygiene and introducing potential contaminants during pickling.

Non-reactive surface technology

Stainless steel funnels offer a non-reactive surface technology that prevents chemical reactions with acidic pickling solutions, ensuring purity and safety during the process. Plastic funnels may leach harmful substances or absorb odors, compromising the quality and safety of pickled products over time.

Eco-durable funnels

Stainless steel funnels offer superior eco-durability for pickling due to their resistance to corrosion, ease of sterilization, and long-lasting material integrity compared to plastic funnels that can degrade and release microplastics. Choosing stainless steel funnels reduces environmental impact and ensures safe, consistent food preservation by avoiding chemical leaching and waste generated from disposable plastic alternatives.

Reusable preservation grade

Stainless steel funnels are highly recommended for pickling due to their durability, resistance to corrosion, and food-grade properties, ensuring safe and reusable preservation-grade use without leaching harmful substances. Plastic funnels, while lightweight and affordable, may degrade over time or react with acidic pickling solutions, potentially compromising the quality and safety of preserved goods.

Plastic funnel vs Stainless steel funnel for pickling. Infographic

cookingdiff.com

cookingdiff.com