Choosing between a regular lid and an airlock lid for pickling directly impacts fermentation quality and safety. Regular lids can trap gases, increasing pressure and risking jar explosions, while airlock lids allow carbon dioxide to escape without letting contaminants in, promoting consistent fermentation. Airlock lids also reduce the risk of mold growth by maintaining an anaerobic environment, essential for crisp, safe pickles.

Table of Comparison

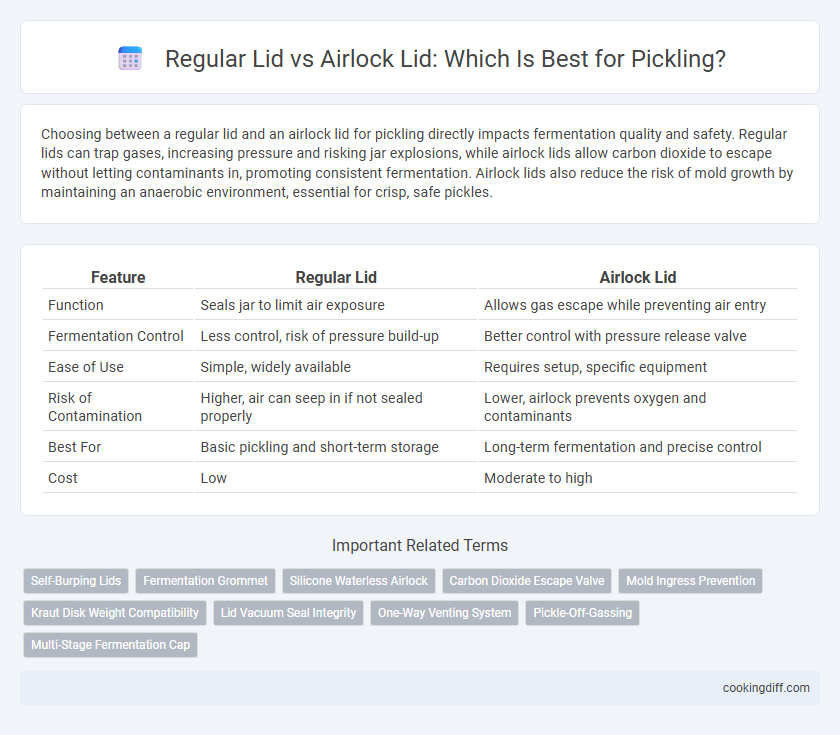

| Feature | Regular Lid | Airlock Lid |

|---|---|---|

| Function | Seals jar to limit air exposure | Allows gas escape while preventing air entry |

| Fermentation Control | Less control, risk of pressure build-up | Better control with pressure release valve |

| Ease of Use | Simple, widely available | Requires setup, specific equipment |

| Risk of Contamination | Higher, air can seep in if not sealed properly | Lower, airlock prevents oxygen and contaminants |

| Best For | Basic pickling and short-term storage | Long-term fermentation and precise control |

| Cost | Low | Moderate to high |

Introduction to Pickling and Lid Options

Pickling preserves vegetables by fermenting them in a brine solution, requiring a sealed container to control the environment. Choosing the right lid impacts the fermentation process and final flavor quality.

- Regular Lid - Creates an airtight seal that prevents contaminants but can trap gases, risking jar breakage during fermentation.

- Airlock Lid - Allows carbon dioxide to escape while preventing oxygen from entering, promoting safer and more controlled fermentation.

- Fermentation Control - Proper lid selection helps maintain anaerobic conditions essential for effective pickling and enhances flavor development.

Using an airlock lid is generally preferred for consistent, safe fermentation, while regular lids require careful monitoring of pressure buildup.

What Is a Regular Pickling Lid?

A regular pickling lid is a simple, flat metal or plastic cover that seals the jar to prevent contaminants from entering during the pickling process. It does not have any built-in mechanism to release gases produced by fermentation, requiring manual venting to avoid pressure buildup.

- Basic Seal - It provides an airtight seal to protect pickles from external bacteria and mold.

- Manual Venting Needed - Gas buildup must be released by loosening the lid periodically to prevent jar breakage.

- Common Use - Regular lids are typically used for vinegar-based pickles rather than naturally fermented ones.

Understanding Airlock Lids in Pickling

Airlock lids are designed to release gases produced during fermentation while preventing oxygen and contaminants from entering the pickling jar, ensuring an anaerobic environment essential for proper fermentation. Regular lids, on the other hand, seal airtight without allowing gas to escape, which can cause pressure buildup and potential jar breakage.

Using an airlock lid simplifies monitoring the fermentation process by reducing the risk of mold and spoilage, as it maintains a controlled atmosphere. This makes airlock lids especially suitable for long-term fermentations like sauerkraut and kimchi, where consistent anaerobic conditions are critical for flavor development and food safety.

Key Differences: Regular Lid vs Airlock Lid

Regular lids on pickling jars provide a simple seal but lack an airlock mechanism, which can lead to exposure to oxygen and potential spoilage. Airlock lids allow carbon dioxide to escape while preventing oxygen and contaminants from entering, creating an anaerobic environment essential for safe fermentation. This key difference affects the texture, flavor, and shelf life of pickled products.

Fermentation Process: Impact of Lid Choice

The choice between a regular lid and an airlock lid significantly influences the fermentation process in pickling by controlling oxygen exposure and gas release. An airlock lid allows carbon dioxide to escape while preventing oxygen entry, creating an anaerobic environment essential for lactic acid bacteria growth and preventing mold formation. Regular lids may trap gases or allow oxygen in, risking spoilage and inconsistent fermentation results.

Oxygen Control: Benefits of Airlock Lids

How does oxygen control differ between regular lids and airlock lids in pickling? Airlock lids allow carbon dioxide to escape while preventing oxygen from entering, reducing the risk of mold and spoilage. This controlled environment enhances fermentation quality and extends the shelf life of pickled products.

Mold and Contamination Risks Compared

Regular lids in pickling jars often increase the risk of mold and contamination due to limited gas escape, creating a moist environment conducive to bacterial growth. Mold growth is more prevalent under regular lids as trapped carbon dioxide and lack of oxygen exchange foster anaerobic conditions.

Airlock lids allow carbon dioxide to escape while preventing oxygen entry, significantly reducing mold and contamination risks by maintaining a controlled anaerobic atmosphere. The design of airlock lids minimizes spoilage, ensuring safer fermentation and longer shelf life for pickled products.

Flavor and Texture: Does the Lid Matter?

The choice between a regular lid and an airlock lid can impact the flavor and texture of pickled products due to varying levels of oxygen exposure. Airlock lids minimize air contact, promoting anaerobic fermentation that enhances tangy flavors and crisp textures.

Regular lids may allow slight oxygen infiltration, potentially leading to softer pickles and less complex flavors from aerobic bacteria activity. Airlock lids maintain a consistent fermentation environment, preserving the desired crunch and depth of flavor. Selecting the correct lid ensures optimal microbial activity for superior pickling results.

Cost and Availability of Each Lid Type

Regular lids for pickling are widely available and generally less expensive, making them a budget-friendly option for most home canners. Airlock lids, while costlier and sometimes harder to find, offer better fermentation control by allowing gases to escape without letting contaminants in.

- Cost-Effectiveness - Regular lids cost significantly less than airlock lids, appealing to cost-conscious users.

- Availability - Regular lids are commonly sold at grocery and hardware stores worldwide.

- Specialized Purchase - Airlock lids often require purchase from specialty fermentation or online stores, impacting accessibility.

Related Important Terms

Self-Burping Lids

Self-burping lids in pickling jars provide an automatic release of gases produced during fermentation, preventing pressure buildup without manual intervention. Unlike regular lids, these airlock systems maintain an anaerobic environment while minimizing the risk of spoilage and mold.

Fermentation Grommet

A fermentation grommet in airlock lids allows carbon dioxide to escape while preventing oxygen and contaminants from entering, ensuring an anaerobic environment ideal for pickling. Regular lids lack this feature, which can lead to pressure buildup or spoilage due to exposure to oxygen during fermentation.

Silicone Waterless Airlock

Silicone waterless airlock lids provide an airtight seal that prevents oxygen exposure, crucial for preventing mold and promoting anaerobic fermentation during pickling. Compared to regular lids, these airlock lids allow carbon dioxide to escape without letting contaminants in, ensuring safer, fresher, and more flavorful fermented vegetables.

Carbon Dioxide Escape Valve

An airlock lid features a built-in carbon dioxide escape valve that allows gases produced during fermentation to safely release, preventing pressure buildup and reducing the risk of jar explosions. In contrast, a regular lid lacks this specialized valve, often requiring manual burping to release excess CO2 and avoid spoilage.

Mold Ingress Prevention

Airlock lids provide a controlled fermentation environment by allowing gases to escape while preventing mold ingress, unlike regular lids which can trap moisture and oxygen, creating ideal conditions for mold growth. Employing airlock lids in pickling significantly reduces the risk of contamination, ensuring a safer and longer-lasting preservation process.

Kraut Disk Weight Compatibility

Regular lids often lack compatibility with kraut disks and weights, risking improper fermentation due to air exposure. Airlock lids are specifically designed to fit kraut disks, ensuring effective weight distribution and maintaining an anaerobic environment crucial for optimal pickling results.

Lid Vacuum Seal Integrity

Regular lids rely on manual tightening to create a vacuum seal, which can be inconsistent and may lead to spoilage or contamination during pickling. Airlock lids feature a built-in valve that automatically releases gas while maintaining vacuum seal integrity, ensuring a more reliable and safer fermentation process.

One-Way Venting System

Regular lids for pickling offer a simple seal but lack a one-way venting system, which can lead to pressure buildup and potential spoilage. Airlock lids feature a one-way venting mechanism that allows gases to escape while preventing oxygen and contaminants from entering, ensuring safer fermentation and extended shelf life.

Pickle-Off-Gassing

Regular lids can trap pickle-off-gassing, potentially causing pressure buildup and spoilage due to lack of ventilation, while airlock lids allow carbon dioxide to escape safely, preventing contamination and maintaining optimal fermentation conditions. Using airlock lids enhances fermentation control by reducing the risk of anaerobic spoilage and off-flavors from trapped gases.

Regular Lid vs Airlock Lid for pickling. Infographic

cookingdiff.com

cookingdiff.com