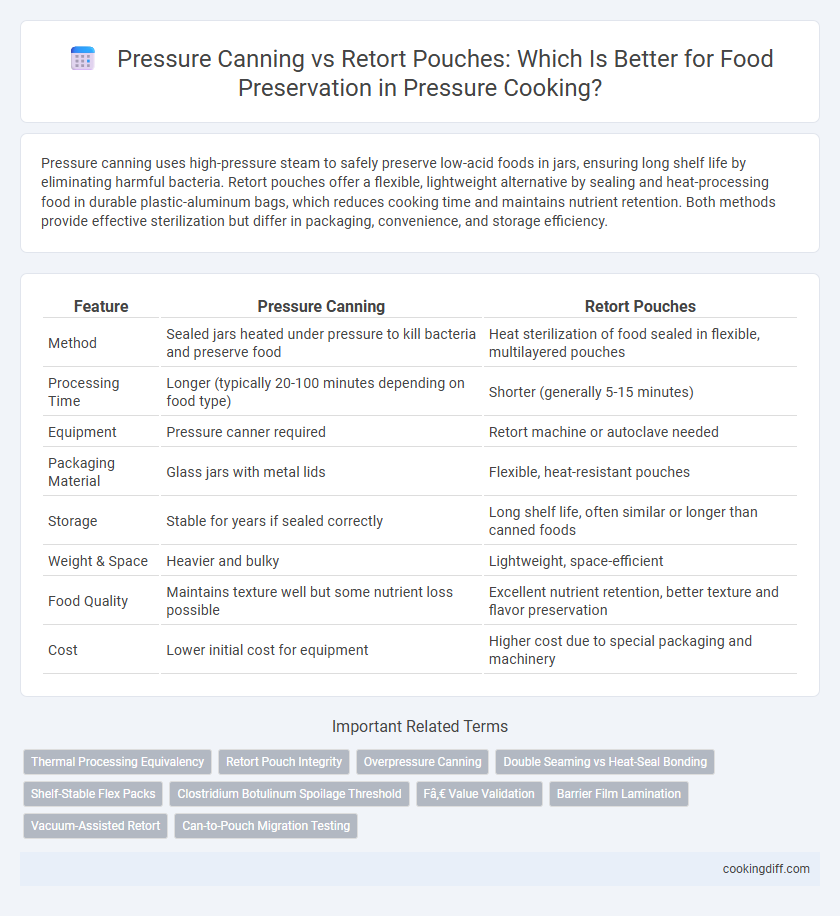

Pressure canning uses high-pressure steam to safely preserve low-acid foods in jars, ensuring long shelf life by eliminating harmful bacteria. Retort pouches offer a flexible, lightweight alternative by sealing and heat-processing food in durable plastic-aluminum bags, which reduces cooking time and maintains nutrient retention. Both methods provide effective sterilization but differ in packaging, convenience, and storage efficiency.

Table of Comparison

| Feature | Pressure Canning | Retort Pouches |

|---|---|---|

| Method | Sealed jars heated under pressure to kill bacteria and preserve food | Heat sterilization of food sealed in flexible, multilayered pouches |

| Processing Time | Longer (typically 20-100 minutes depending on food type) | Shorter (generally 5-15 minutes) |

| Equipment | Pressure canner required | Retort machine or autoclave needed |

| Packaging Material | Glass jars with metal lids | Flexible, heat-resistant pouches |

| Storage | Stable for years if sealed correctly | Long shelf life, often similar or longer than canned foods |

| Weight & Space | Heavier and bulky | Lightweight, space-efficient |

| Food Quality | Maintains texture well but some nutrient loss possible | Excellent nutrient retention, better texture and flavor preservation |

| Cost | Lower initial cost for equipment | Higher cost due to special packaging and machinery |

Introduction to Modern Food Preservation Methods

Pressure canning and retort pouches are advanced techniques in modern food preservation that ensure safety and shelf stability through high-temperature processing. Both methods use controlled heat and pressure to eliminate harmful microorganisms, extending the shelf life of various food products.

- Pressure Canning - Utilizes a sealed jar and steam under pressure to kill bacteria and spores, ideal for home preservation of low-acid foods.

- Retort Pouches - Flexible, heat-resistant packaging subjected to pressure sterilization, commonly used in commercial food processing for lightweight, space-saving storage.

- Microbial Safety - Both methods achieve commercial sterility by reaching temperatures above 121degC (250degF), ensuring food safety and quality.

Integrating pressure canning and retort pouches exemplifies advancements in food technology focused on preservation efficiency and consumer convenience.

What is Pressure Canning?

Pressure canning is a food preservation method that uses high pressure to achieve temperatures above boiling, effectively killing harmful bacteria and spores. It is particularly suitable for low-acid foods such as vegetables, meats, and poultry, ensuring long-term shelf stability without refrigeration.

- High-Pressure Environment - Pressure canning operates at 10-15 psi, reaching temperatures of 240-250degF to sterilize food safely.

- Suitable for Low-Acid Foods - This method is essential for preserving meats and vegetables that cannot be safely canned by boiling water methods.

- Extended Shelf Life - Properly pressure canned foods can be stored for up to one year while maintaining nutritional quality and safety.

Understanding Retort Pouches

Retort pouches offer a flexible, space-saving alternative to traditional pressure canning by utilizing a multilayer laminated film that withstands high temperatures and pressure. These pouches enable rapid heat transfer, reducing cooking time while maintaining food safety and nutritional quality. Commonly used in commercial food preservation, retort pouches provide extended shelf life without refrigeration compared to conventional glass jars used in pressure canning.

Pressure Canning Process: Step-by-Step

The pressure canning process begins by filling jars with prepared food, leaving appropriate headspace, then sealing them with lids. Jars are placed inside the pressure canner, water is added, and the lid is secured to create an airtight environment necessary for reaching high temperatures.

The canner is heated to build steam pressure, typically reaching 10 to 15 psi, which raises the boiling point of water to kill bacteria and spores effectively. Processing times vary depending on food type and jar size, ensuring safety and preservation. Once complete, the canner is depressurized naturally before opening to avoid jar breakage and ensure a proper vacuum seal.

How Retort Pouch Processing Works

Retort pouch processing involves sealing food in flexible, multi-layered pouches that are then heated under pressure to achieve sterilization. This method uses saturated steam or hot water to raise the internal temperature, effectively killing microbes and preserving the food without compromising nutritional quality or taste.

- Flexible Packaging - Retort pouches are made from laminated materials that combine metal and plastic layers for durability and heat resistance.

- High-Temperature Sterilization - The pouches are processed at temperatures around 121degC (250degF) in pressure vessels to ensure the destruction of pathogenic bacteria.

- Rapid Cooling - After heating, pouches undergo rapid cooling to prevent overprocessing and maintain texture and flavor of the preserved food.

Shelf Life and Food Safety Comparison

Pressure canning extends shelf life up to one year for low-acid foods by achieving temperatures above 240degF, effectively eliminating Clostridium botulinum spores for optimal food safety. Retort pouches undergo high-heat sterilization at similar temperatures, offering comparable shelf stability of 12 to 18 months while maintaining food quality and safety. Both methods provide reliable commercial sterility, but retort pouches offer faster processing times and reduced nutrient degradation compared to traditional pressure canning.

Nutritional Retention: Canning vs Retort Pouches

Pressure canning preserves food by using high temperatures to eliminate bacteria, but it may cause some nutrient loss, particularly water-soluble vitamins such as vitamin C and B vitamins. Retort pouches, made from laminated plastic and aluminum foil, use rapid heating which can better preserve heat-sensitive nutrients compared to traditional canning.

Studies indicate that retort pouch processing often results in higher retention of antioxidants and vitamins due to shorter processing times and minimal oxygen exposure. Both methods ensure long shelf life, but retort pouches offer improved nutritional quality while maintaining food safety and convenience.

Equipment and Cost Considerations

| Method | Equipment | Cost Considerations |

|---|---|---|

| Pressure Canning | Pressure canner, jars, lids | Initial investment in canner and jars, ongoing costs for lids and fuel |

| Retort Pouches | Retort machine, specialized pouches | Higher upfront cost for retort equipment, lower packaging material cost per unit |

Environmental Impact and Sustainability

Pressure canning uses reusable glass jars that reduce single-use plastic waste, promoting sustainability by minimizing landfill contributions. Retort pouches, while lightweight and energy-efficient during transport, often rely on multi-layer plastics that are difficult to recycle, posing environmental challenges.

Glass jars from pressure canning can be sterilized and reused countless times, lowering the carbon footprint over years of use compared to disposable retort pouches. The production and disposal of retort pouches generate more greenhouse gases and persistent waste, undermining long-term environmental goals.

Related Important Terms

Thermal Processing Equivalency

Pressure canning achieves superior thermal processing equivalency by maintaining consistent high temperatures (240-250degF) under controlled pressure, ensuring effective microbial inactivation for low-acid foods. Retort pouches offer comparable sterilization levels through uniform heat penetration and shorter processing times, optimizing nutrient retention while meeting established FDA thermal process standards.

Retort Pouch Integrity

Retort pouches maintain superior integrity under high-temperature, high-pressure conditions during sterilization, ensuring an airtight seal that prevents contamination and preserves food quality longer than traditional pressure canning. The flexible, multi-layered barrier of retort pouches resists punctures and microbial infiltration, making them a reliable option for long-term food preservation compared to rigid metal cans used in pressure canning.

Overpressure Canning

Overpressure canning utilizes pressures exceeding standard pressure canning thresholds to achieve faster sterilization and extended shelf life, particularly effective in low-acid food preservation. Compared to retort pouches, overpressure canning ensures uniform heat distribution and improved microbial inactivation but requires specific equipment to maintain higher pressure vessels safely.

Double Seaming vs Heat-Seal Bonding

Pressure canning relies on double seaming to create airtight, durable seals on metal cans, ensuring safe preservation by preventing microbial contamination under high pressure and temperature. In contrast, retort pouches use heat-seal bonding of multiple flexible layers, offering lightweight, space-efficient packaging with rapid heat penetration while maintaining sterility during pressure cooking.

Shelf-Stable Flex Packs

Pressure canning ensures safe, long-term preservation by using high heat and pressure to eliminate bacteria in jars, while retort pouches, or Shelf-Stable Flex Packs, offer lightweight, space-saving packaging with extended shelf life through thermal processing. Shelf-Stable Flex Packs provide superior oxygen and moisture barriers, enhancing food quality retention and convenience compared to traditional pressure-canned jars.

Clostridium Botulinum Spoilage Threshold

Pressure canning effectively destroys Clostridium botulinum spores by reaching temperatures above 240degF (116degC), ensuring safe preservation of low-acid foods through pressurized steam. Retort pouches also achieve this sterilization by withstanding similar thermal processing conditions, but their thin packaging allows faster heat penetration, reducing spoilage risk within the Clostridium botulinum spoilage threshold more efficiently.

F₀ Value Validation

Pressure canning achieves precise F0 value validation through regulated temperature and pressure cycles, ensuring effective sterilization for low-acid foods. Retort pouches rely on validated thermal processes to maintain consistent F0 values, offering enhanced heat penetration and faster processing times compared to traditional pressure canning.

Barrier Film Lamination

Barrier film lamination in pressure canning provides a multi-layered protective shield that enhances oxygen and moisture resistance, crucial for extending shelf life and preserving food quality. Retort pouches utilize advanced barrier films with aluminum or metallized layers, offering superior thermal stability and flexibility for efficient heat penetration during sterilization, optimizing food safety and nutrient retention.

Vacuum-Assisted Retort

Vacuum-assisted retort technology enhances food preservation by removing air from retort pouches prior to pressure cooking, minimizing oxidation and microbial growth compared to traditional pressure canning. This method extends shelf life while maintaining nutrient retention and texture, offering a more efficient and safer alternative for long-term food storage.

Pressure canning vs retort pouches for food preservation. Infographic

cookingdiff.com

cookingdiff.com