Manual release valves in pressure cookers offer precise control over steam release, allowing pet owners to carefully regulate cooking pressure and prevent overcooking delicate pet foods. Automatic pressure release systems provide convenience by safely venting steam without user intervention, reducing the risk of burns but potentially releasing pressure too quickly for sensitive recipes. Choosing between manual and automatic pressure release depends on the desired balance between control, safety, and ease of use when preparing nutritious meals for pets.

Table of Comparison

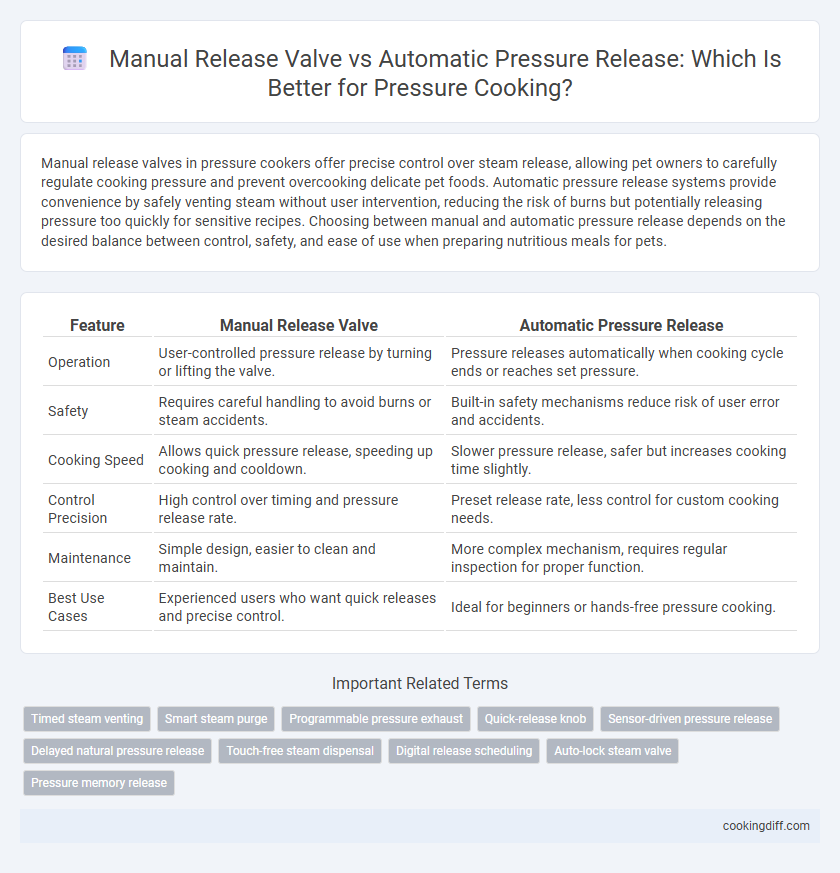

| Feature | Manual Release Valve | Automatic Pressure Release |

|---|---|---|

| Operation | User-controlled pressure release by turning or lifting the valve. | Pressure releases automatically when cooking cycle ends or reaches set pressure. |

| Safety | Requires careful handling to avoid burns or steam accidents. | Built-in safety mechanisms reduce risk of user error and accidents. |

| Cooking Speed | Allows quick pressure release, speeding up cooking and cooldown. | Slower pressure release, safer but increases cooking time slightly. |

| Control Precision | High control over timing and pressure release rate. | Preset release rate, less control for custom cooking needs. |

| Maintenance | Simple design, easier to clean and maintain. | More complex mechanism, requires regular inspection for proper function. |

| Best Use Cases | Experienced users who want quick releases and precise control. | Ideal for beginners or hands-free pressure cooking. |

Introduction to Pressure-Cooking Release Methods

Manual release valves in pressure cookers require the user to carefully control the steam release, allowing precise pressure adjustment and preventing overcooking. Automatic pressure release systems use built-in mechanisms to safely and gradually reduce pressure without user intervention, enhancing convenience and safety. Understanding the differences in release methods is essential for optimizing cooking times and ensuring safety during pressure-cooking.

What Is a Manual Release Valve?

| The manual release valve in pressure cookers allows users to control the steam release manually, providing precise pressure management during cooking. |

| This valve typically requires turning or lifting to release pressure, ensuring safety and preventing sudden steam bursts. |

| Manual release valves offer flexibility for recipes needing gradual pressure reduction, enhancing cooking accuracy and food texture. |

How Does Automatic Pressure Release Work?

The automatic pressure release mechanism in pressure cookers functions by gradually venting steam once the cooking cycle ends, preventing sudden pressure drops. This controlled release is achieved through built-in valves that open at a specific pressure level to maintain safety and cooking consistency.

Automatic pressure release works by sensing the internal pressure and activating the venting system without user intervention. The valve releases steam slowly to avoid splattering or burns that can occur with manual release. This feature enhances convenience and ensures proteins and liquids stay intact, preserving the texture and flavor of the cooked food.

Key Differences: Manual vs Automatic Pressure Release

Manual release valves require the user to physically turn or lift the valve to release steam, offering precise control over the pressure drop and cooking time. Automatic pressure release systems engage automatically once cooking is complete, enhancing safety by preventing accidental burns and maintaining consistent pressure levels. Choosing between manual and automatic release depends on user preference for control versus convenience in pressure-cooking operations.

Safety Considerations for Manual and Automatic Release

Manual release valves in pressure cookers allow for controlled venting of steam, reducing the risk of sudden pressure drops that could cause burns or food splatter. Users must carefully operate these valves to ensure safety, as improper handling can lead to dangerous steam exposure.

Automatic pressure release mechanisms are designed to release steam safely without user intervention, minimizing the risk of accidents during the pressure release process. These systems often include fail-safes to prevent pressure buildup beyond safe limits, enhancing overall cooker safety.

Impact on Cooking Time and Food Texture

How does the choice between manual release valve and automatic pressure release impact cooking time and food texture in pressure-cooking? Manual release valves slow down the pressure reduction, resulting in longer cooking times that allow tougher foods to become tender and retain moisture. Automatic pressure release speeds up the cooking process but can cause abrupt texture changes, sometimes making delicate foods overcooked or mushy.

User Experience: Convenience and Control

Manual release valves offer precise control over steam release, allowing users to quickly adjust pressure levels according to specific recipes. This hands-on approach enhances the cooking experience by providing immediate feedback and customization during pressure-cooking.

Automatic pressure release systems prioritize convenience, safely and gradually lowering the pressure without user intervention. This feature reduces the risk of burns and simplifies the process, making pressure-cooking accessible for beginners and busy cooks alike.

Maintenance and Durability: Manual vs Automatic

Manual release valves in pressure cookers generally require more frequent maintenance due to their mechanical components exposed to wear from constant handling. Automatic pressure release systems are designed with fewer moving parts, enhancing durability and reducing the need for regular maintenance.

- Manual Valve Complexity - Manual valves involve seals and springs that can degrade faster with repeated use, necessitating careful inspection.

- Automatic System Robustness - Automatic release mechanisms are often sealed units, minimizing exposure to food residue and moisture.

- Longevity Impact - Cookers with automatic release valves tend to maintain pressure integrity longer due to less manual interference.

Choosing an automatic pressure release can improve overall pressure cooker lifespan and simplify upkeep for consistent kitchen performance.

Best Use Cases for Each Pressure Release Method

Manual release valves offer precise control for quickly stopping the cooking process, ideal for delicate ingredients that can overcook easily. Automatic pressure release provides convenience and safety by slowly releasing steam without user intervention, best for recipes requiring gradual depressurization.

- Manual release valve - Best for meats and vegetables needing immediate pressure reduction to maintain texture and prevent overcooking.

- Automatic pressure release - Suitable for soups and stews where gradual pressure reduction preserves moisture and flavor.

- Safety considerations - Automatic release minimizes burns risk by controlling steam release rate, while manual release demands careful handling.

Related Important Terms

Timed steam venting

Manual release valves in pressure cookers allow users to control steam venting precisely, enabling timed steam release to prevent overcooking and maintain optimal pressure levels. In contrast, automatic pressure release systems use sensors to trigger timed steam venting for consistent pressure reduction, enhancing safety and convenience during the cooking process.

Smart steam purge

Manual release valves provide precise control over pressure reduction, allowing cooks to manage cooking times and textures effectively, while automatic pressure release systems utilize smart steam purge technology to safely and efficiently vent steam without user intervention, minimizing risk and enhancing convenience. Smart steam purge optimizes cooking safety and performance by detecting and releasing excess pressure automatically, ensuring consistent results and protecting the appliance from potential damage.

Programmable pressure exhaust

Programmable pressure exhaust systems in pressure cookers offer precise control over steam release, enhancing safety and cooking consistency compared to manual release valves that require user intervention. These automated mechanisms optimize cooking cycles by adjusting pressure release based on preset programs, reducing the risk of overcooking and improving overall efficiency.

Quick-release knob

The quick-release knob on a pressure cooker allows for manual pressure release, providing precise control over cooking time to prevent overcooking delicate foods. Unlike automatic pressure release systems, the manual valve requires user intervention to safely and rapidly release steam, enhancing flexibility and efficiency in pressure-cooking processes.

Sensor-driven pressure release

Sensor-driven pressure release systems in pressure cookers provide precise, automated control over internal pressure by continuously monitoring temperature and pressure levels, enhancing safety and cooking efficiency. Unlike manual release valves that require user intervention, these advanced systems adjust pressure release dynamically, minimizing risks of overpressure and ensuring optimal cooking conditions.

Delayed natural pressure release

Delayed natural pressure release allows pressure to decrease gradually inside the cooker, preserving food texture and preventing splattering compared to manual release valve methods. This automatic pressure release technique enhances safety and maintains nutrients by avoiding sudden pressure drops common with manual valve use.

Touch-free steam dispensal

Manual release valves in pressure cookers require the user to physically turn or lift a valve to release steam, increasing the risk of burns from hot steam exposure. Automatic pressure release systems enable touch-free steam dispensal by safely venting steam without user contact, enhancing kitchen safety and reducing the chance of accidental scalding.

Digital release scheduling

The digital release scheduling feature in modern pressure cookers allows precise control over pressure release timing, optimizing cooking results by balancing safety and efficiency better than manual release valves. Automatic pressure release systems integrate with digital timers to manage pressure expulsion smoothly, reducing user intervention and enhancing consistent meal preparation.

Auto-lock steam valve

The auto-lock steam valve in pressure cookers ensures precise pressure control by automatically sealing and releasing steam only when optimal pressure levels are reached, enhancing safety and cooking efficiency. Unlike manual release valves, this mechanism prevents accidental steam burns and maintains consistent cooking results through regulated steam discharge.

Manual release valve vs Automatic pressure release for pressure-cooking. Infographic

cookingdiff.com

cookingdiff.com