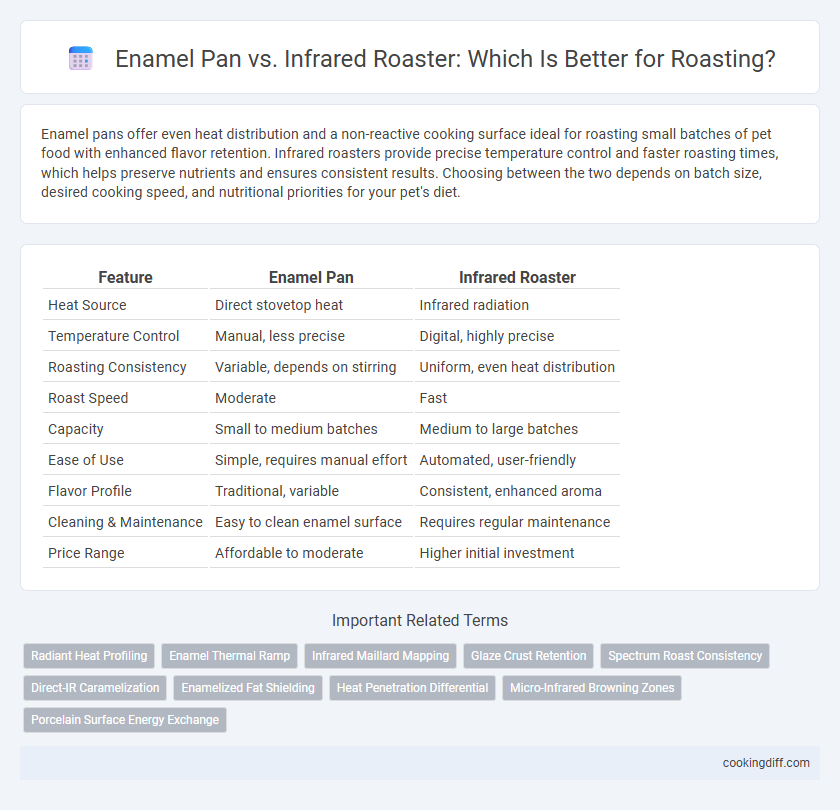

Enamel pans offer even heat distribution and a non-reactive cooking surface ideal for roasting small batches of pet food with enhanced flavor retention. Infrared roasters provide precise temperature control and faster roasting times, which helps preserve nutrients and ensures consistent results. Choosing between the two depends on batch size, desired cooking speed, and nutritional priorities for your pet's diet.

Table of Comparison

| Feature | Enamel Pan | Infrared Roaster |

|---|---|---|

| Heat Source | Direct stovetop heat | Infrared radiation |

| Temperature Control | Manual, less precise | Digital, highly precise |

| Roasting Consistency | Variable, depends on stirring | Uniform, even heat distribution |

| Roast Speed | Moderate | Fast |

| Capacity | Small to medium batches | Medium to large batches |

| Ease of Use | Simple, requires manual effort | Automated, user-friendly |

| Flavor Profile | Traditional, variable | Consistent, enhanced aroma |

| Cleaning & Maintenance | Easy to clean enamel surface | Requires regular maintenance |

| Price Range | Affordable to moderate | Higher initial investment |

Introduction: Enamel Pan vs Infrared Roaster for Roasting

Enamel pans and infrared roasters offer distinct approaches to roasting, each impacting flavor and texture uniquely. Understanding their differences assists in choosing the optimal method for specific roasting needs.

- Enamel Pan - Provides even heat distribution ideal for slow roasting and tender results.

- Infrared Roaster - Uses infrared radiation to roast quickly while preserving moisture and enhancing caramelization.

- Heat Control - Enamel pans allow for manual temperature adjustments, while infrared roasters maintain consistent heat through advanced technology.

Selecting between enamel pans and infrared roasters depends on roasting speed, desired flavor profile, and temperature precision.

What is an Enamel Pan?

An enamel pan is a cooking vessel coated with a smooth, durable layer of enamel fused to metal, often cast iron or steel, providing excellent heat retention and a non-reactive surface ideal for roasting. It allows even heat distribution while preventing food from sticking and reacting with the pan material.

- Material - Typically made from cast iron or steel with a porcelain enamel coating enhancing durability and heat retention.

- Heat Retention - Maintains consistent heat, making it suitable for slow roasting and searing meats evenly.

- Non-Reactive Surface - The enamel coating prevents chemical reactions with acidic foods, preserving flavor integrity during roasting.

What is an Infrared Roaster?

What is an infrared roaster and how does it differ from an enamel pan? An infrared roaster uses infrared radiation to evenly distribute heat, providing precise temperature control for consistent roasting results. Unlike enamel pans, which rely on direct contact heat, infrared roasters minimize hot spots and enhance flavor development by roasting beans more uniformly.

Heat Distribution: Enamel Pan vs Infrared Roaster

Enamel pans provide consistent heat distribution due to their thick, heavy base that retains and spreads heat evenly across the surface. Infrared roasters utilize radiant heat to cook food quickly and uniformly, minimizing hot spots and preserving flavor through precise temperature control. Comparing both, enamel pans excel in gradual, steady heating while infrared roasters offer rapid, intense heat with superior thermal efficiency for roasting tasks.

Roasting Quality and Flavor Outcome

| Enamel pans provide even heat distribution, enhancing Maillard reactions for a richer, caramelized flavor in roasted beans. |

| Infrared roasters offer precise temperature control and rapid heat transfer, preserving delicate aromatic compounds and delivering a consistent roast profile. |

| Overall, enamel pans produce deeper, more complex flavor notes, while infrared roasters excel in clarity and uniformity of roasting outcomes. |

Cooking Time Comparison

Enamel pans typically require longer cooking times due to their slower heat conduction, often extending roasting sessions by up to 20% compared to infrared roasters. Infrared roasters use intense, direct heat that accelerates cooking, reducing the time needed to evenly roast beans or meats.

Infrared roasters can complete a roast in approximately 15 to 20 minutes, while enamel pans may take 25 to 30 minutes depending on the quantity and heat source. This difference in cooking time impacts energy efficiency and can influence flavor development in the final roast.

Ease of Use and Cleaning

Enamel pans offer straightforward use with even heat distribution, making them user-friendly for home roasting enthusiasts. Infrared roasters provide precise temperature control but often require more complex setup and maintenance. Cleaning enamel pans is simple due to their smooth surface, while infrared roasters may involve disassembling parts for thorough cleaning.

Durability and Lifespan

Enamel pans offer excellent durability due to their chip-resistant, non-porous surface that withstands high temperatures without degrading over time. These pans maintain their integrity for years, making them a reliable choice for consistent roasting results.

Infrared roasters, equipped with advanced heating elements, deliver precise temperature control, but their lifespan depends heavily on the quality of components like the quartz tubes and reflectors. While they provide efficient roasting, regular maintenance is crucial to ensure long-term durability and optimal performance.

Cost and Value Analysis

Enamel pans offer a budget-friendly option with low upfront costs, ideal for small-batch roasting but require careful temperature control to avoid uneven roasting. Infrared roasters come with a higher price tag yet provide consistent heat distribution and faster roasting times, improving overall efficiency and product quality.

While enamel pans are durable and simple to maintain, their manual operation can lead to inconsistent roasts, affecting the final flavor and yield. Infrared roasters, despite the initial investment, reduce energy consumption and labor costs over time, increasing the return on investment. Choosing between the two depends on scale, precision needs, and long-term cost-effectiveness for roasting operations.

Related Important Terms

Radiant Heat Profiling

Enamel pans provide consistent radiant heat distribution ideal for even roasting, as the coated surface retains and reflects heat uniformly, enhancing flavor development. Infrared roasters utilize focused radiant heat waves that penetrate beans directly, offering precise temperature control and rapid heat transfer for efficient roasting cycles.

Enamel Thermal Ramp

Enamel pans provide a gradual thermal ramp that ensures even heat distribution, crucial for gently developing complex flavors during roasting, contrasting with the rapid heat spikes typical of infrared roasters. This controlled temperature increase in enamel pans minimizes scorching and promotes uniform chemical reactions, enhancing the final roast profile.

Infrared Maillard Mapping

Infrared roasters utilize precise Maillard mapping technology that evenly distributes heat, ensuring consistent caramelization and enhanced flavor development during roasting. Unlike enamel pans, which often produce uneven heat spots, infrared Maillard mapping enables superior control over temperature gradients, resulting in a more uniform roast profile.

Glaze Crust Retention

Enamel pans provide superior glaze crust retention during roasting due to their even heat distribution and non-reactive surface, which helps maintain the integrity of the caramelized layer. Infrared roasters, while efficient at high-temperature cooking, may cause uneven glazing because of direct radiant heat, potentially compromising crust consistency.

Spectrum Roast Consistency

Enamel pans provide uneven heat distribution, often causing inconsistent roast spectrum with hotspots and cooler areas, resulting in varied roast profiles within a single batch. Infrared roasters utilize uniform radiant heat, ensuring precise temperature control and consistent spectrum roast throughout the process, optimizing flavor development.

Direct-IR Caramelization

Enamel pans enable consistent direct-IR caramelization by evenly distributing heat across the surface, enhancing Maillard reactions and producing rich, deep flavors. Infrared roasters deliver intense, focused IR radiation that accelerates caramelization and creates a distinctive crust but may require precise control to avoid burning or uneven roasting.

Enamelized Fat Shielding

Enamel pans provide an enamelized fat shielding layer that prevents direct contact between the food and the heat source, promoting even roasting and preserving natural juices. Infrared roasters use radiant heat for rapid cooking but lack the protective enamel layer, which can lead to uneven roasting and potential fat degradation.

Heat Penetration Differential

Enamel pans provide more even heat distribution due to their thick metal base coated with enamel, allowing steady heat penetration ideal for consistent roasting. Infrared roasters emit concentrated radiant heat that penetrates quickly and deeply into the food, resulting in faster cooking and distinct browning effects compared to enamel pans.

Micro-Infrared Browning Zones

Enamel pans provide even heat distribution but lack the precision of micro-infrared browning zones found in infrared roasters, which enable targeted caramelization for enhanced flavor and consistent roast profiles. Infrared technology generates intense, localized heat, optimizing Maillard reactions and producing superior crust development compared to traditional enamel roasting methods.

Enamel Pan vs Infrared Roaster for roasting. Infographic

cookingdiff.com

cookingdiff.com