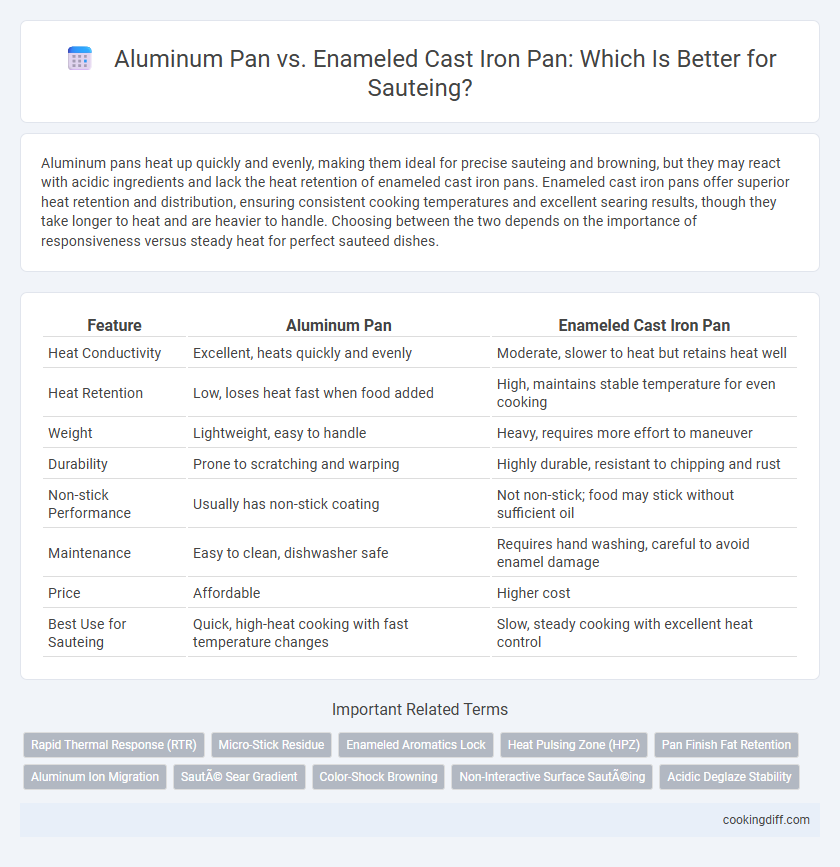

Aluminum pans heat up quickly and evenly, making them ideal for precise sauteing and browning, but they may react with acidic ingredients and lack the heat retention of enameled cast iron pans. Enameled cast iron pans offer superior heat retention and distribution, ensuring consistent cooking temperatures and excellent searing results, though they take longer to heat and are heavier to handle. Choosing between the two depends on the importance of responsiveness versus steady heat for perfect sauteed dishes.

Table of Comparison

| Feature | Aluminum Pan | Enameled Cast Iron Pan |

|---|---|---|

| Heat Conductivity | Excellent, heats quickly and evenly | Moderate, slower to heat but retains heat well |

| Heat Retention | Low, loses heat fast when food added | High, maintains stable temperature for even cooking |

| Weight | Lightweight, easy to handle | Heavy, requires more effort to maneuver |

| Durability | Prone to scratching and warping | Highly durable, resistant to chipping and rust |

| Non-stick Performance | Usually has non-stick coating | Not non-stick; food may stick without sufficient oil |

| Maintenance | Easy to clean, dishwasher safe | Requires hand washing, careful to avoid enamel damage |

| Price | Affordable | Higher cost |

| Best Use for Sauteing | Quick, high-heat cooking with fast temperature changes | Slow, steady cooking with excellent heat control |

Introduction to Sautéing: Why Pan Choice Matters

Choosing the right pan significantly impacts sauteing outcomes, with aluminum and enameled cast iron offering distinct advantages. Aluminum pans heat quickly and provide excellent heat conductivity, ideal for delicate ingredients requiring precise temperature control. Enameled cast iron pans retain heat longer and ensure even cooking, making them suitable for sautes needing consistent heat distribution.

Aluminum Pans: Key Features and Benefits

Aluminum pans offer exceptional thermal conductivity, allowing for quick and even heating essential for perfect sauteing. Their lightweight design provides excellent maneuverability, making it easier to toss and turn ingredients with precision.

- Superior Heat Conduction - Aluminum distributes heat rapidly and evenly, preventing hot spots during sauteing.

- Lightweight Construction - Easier to handle and control, ideal for fast cooking techniques like sauteing.

- Responsive to Temperature Changes - Quickly adjusts to heat adjustments, enabling precise cooking control.

Enameled Cast Iron Pans: Characteristics and Advantages

Enameled cast iron pans provide superior heat retention and even heat distribution, ideal for precise sauteing control. Their non-reactive surface prevents metallic taste, making them perfect for cooking acidic ingredients.

- Exceptional Heat Retention - Enameled cast iron maintains consistent heat, ensuring food cooks evenly without hot spots.

- Durable Non-Reactive Surface - The enamel coating prevents rust and does not react with acidic foods, preserving flavor integrity.

- Versatility and Longevity - Suitable for stovetop and oven use, these pans last for decades with proper care.

Heat Conductivity: Aluminum vs Enameled Cast Iron

Aluminum pans offer superior heat conductivity, allowing for quick and even heat distribution, which is essential for precise sauteing. This results in faster cooking times and better control over temperature fluctuations.

Enameled cast iron pans have slower heat conductivity but retain heat longer, providing consistent cooking temperatures for sauteing. Although they heat less evenly than aluminum, their heat retention ensures steady cooking without rapid temperature drops.

Weight and Handling: Comparing Pan Maneuverability

Aluminum pans are significantly lighter than enameled cast iron pans, making them easier to maneuver during sauteing. The lightweight design of aluminum allows for quicker wrist movements and better control when tossing ingredients. Conversely, enameled cast iron pans offer superior heat retention but require more strength to handle due to their substantial weight.

Nonstick Performance: Surface Differences in Sautéing

| Pan Type | Surface Material | Nonstick Performance | Durability & Maintenance |

| Aluminum Pan | Uncoated aluminum or anodized | Provides quick heat distribution but usually requires oil or nonstick coating to prevent sticking during sauteing. | Prone to scratching and warping; anodized versions offer better scratch resistance. |

| Enameled Cast Iron Pan | Cast iron base with porcelain enamel coating | Naturally smoother, less sticky surface that improves nonstick performance over time without seasoning. | Highly durable and resistant to rust; requires gentle cleaning to maintain enamel integrity. |

Cleaning and Maintenance Requirements

Which pan is easier to clean after sauteing, aluminum or enameled cast iron? Aluminum pans typically require less effort for cleaning due to their smooth, non-porous surface that resists food sticking. Enameled cast iron pans need careful washing to avoid chipping the enamel and often require hand washing and thorough drying to prevent rust on exposed cast iron edges.

Flavor Impact: Does Pan Material Affect Taste?

Aluminum pans heat quickly and distribute heat evenly but may impart a slight metallic flavor when cooking acidic foods. Enameled cast iron pans retain heat longer, enhancing caramelization and depth of flavor without reacting to ingredients.

- Aluminum Conductivity - Aluminum's high thermal conductivity ensures rapid and even heating, minimizing hotspots during sauteing.

- Flavor Neutrality - Enameled cast iron's non-reactive surface prevents metallic taste transfer, preserving the true flavors of ingredients.

- Heat Retention - The thick walls of enameled cast iron maintain steady temperatures, promoting richer flavor development through consistent browning.

Choosing between an aluminum or enameled cast iron pan significantly affects the taste profile by influencing heat behavior and flavor neutrality during sauteing.

Durability and Longevity: Which Pan Lasts Longer?

Aluminum pans are lightweight and conduct heat quickly but tend to warp and scratch over time, reducing their durability. Enameled cast iron pans, with their robust coated surface, resist chipping and corrosion, offering superior longevity even under frequent high-heat sauteing conditions.

The non-reactive enamel finish protects the cast iron from rusting, ensuring the pan maintains its performance for decades. In contrast, aluminum pans may require replacement every few years due to wear and material degradation during regular sauteing use.

Related Important Terms

Rapid Thermal Response (RTR)

Aluminum pans offer superior rapid thermal response (RTR) due to their excellent heat conductivity, allowing precise temperature control essential for sauteing delicate ingredients. Enameled cast iron pans, while providing even heat distribution and retention, have slower RTR, which can lead to less responsive temperature adjustments during high-heat cooking.

Micro-Stick Residue

Aluminum pans tend to develop micro-stick residue due to their reactive surface and lower heat retention, which can cause food to adhere and leave behind tiny burnt particles during sauteing. Enameled cast iron pans provide a non-reactive, smooth surface that minimizes micro-stick residue by evenly distributing heat and preventing food from sticking.

Enameled Aromatics Lock

Enameled cast iron pans excel at sauteing by evenly distributing heat and locking in the aromas of vegetables and spices, enhancing the depth of flavor in dishes. Unlike aluminum pans, their non-reactive enameled surface prevents metallic taste absorption, preserving the purity of sauteed aromatics.

Heat Pulsing Zone (HPZ)

Aluminum pans offer rapid heat conduction creating a narrow Heat Pulsing Zone (HPZ) that allows quick temperature adjustments ideal for precise sauteing. Enameled cast iron pans have a broader HPZ due to slower heat response, providing steady heat retention but less immediate control over temperature fluctuations during cooking.

Pan Finish Fat Retention

Aluminum pans with their smooth finish offer quick heat responsiveness but typically have lower fat retention, causing oils to spread thinly and evaporate faster during sauteing. In contrast, enameled cast iron pans provide a textured surface that retains fats longer, maintaining even heat distribution and enhancing flavor development in sauteed dishes.

Aluminum Ion Migration

Aluminum pans offer excellent heat conductivity for even sauteing but pose a risk of aluminum ion migration into acidic foods, potentially impacting flavor and health. Enameled cast iron pans prevent aluminum ion transfer due to their non-reactive coating, providing a safer option for sauteing acidic ingredients without compromising heat retention.

Sauté Sear Gradient

Aluminum pans offer superior heat conductivity, creating a rapid saute sear gradient ideal for precise temperature control and quick browning. Enameled cast iron pans provide more even heat retention, producing a gentler saute sear gradient that excels in maintaining consistent cooking temperatures for thicker cuts.

Color-Shock Browning

Aluminum pans heat quickly and evenly, allowing for effective color-shock browning that locks in flavor by rapidly searing the food's surface. Enameled cast iron pans, while slower to heat, maintain high temperatures longer, producing deeper browning with consistent heat retention ideal for sauteing thicker cuts.

Non-Interactive Surface Sautéing

Aluminum pans offer excellent heat conductivity for quick, even cooking during non-interactive surface sauteing, preventing food from sticking and enabling precise temperature control. Enameled cast iron pans provide superior heat retention but feature a less responsive surface, which may result in slower temperature adjustments and increased risk of surface interaction during delicate sauteing tasks.

Aluminum pan vs Enameled cast iron pan for sautéing. Infographic

cookingdiff.com

cookingdiff.com