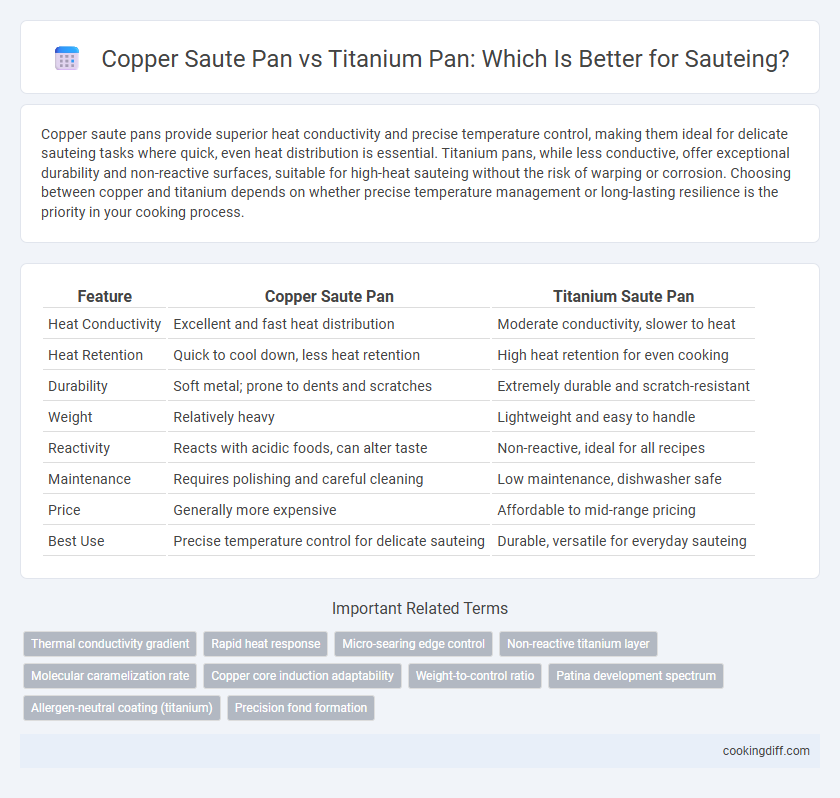

Copper saute pans provide superior heat conductivity and precise temperature control, making them ideal for delicate sauteing tasks where quick, even heat distribution is essential. Titanium pans, while less conductive, offer exceptional durability and non-reactive surfaces, suitable for high-heat sauteing without the risk of warping or corrosion. Choosing between copper and titanium depends on whether precise temperature management or long-lasting resilience is the priority in your cooking process.

Table of Comparison

| Feature | Copper Saute Pan | Titanium Saute Pan |

|---|---|---|

| Heat Conductivity | Excellent and fast heat distribution | Moderate conductivity, slower to heat |

| Heat Retention | Quick to cool down, less heat retention | High heat retention for even cooking |

| Durability | Soft metal; prone to dents and scratches | Extremely durable and scratch-resistant |

| Weight | Relatively heavy | Lightweight and easy to handle |

| Reactivity | Reacts with acidic foods, can alter taste | Non-reactive, ideal for all recipes |

| Maintenance | Requires polishing and careful cleaning | Low maintenance, dishwasher safe |

| Price | Generally more expensive | Affordable to mid-range pricing |

| Best Use | Precise temperature control for delicate sauteing | Durable, versatile for everyday sauteing |

Introduction: Choosing the Best Pan for Sautéing

| Copper Saute Pan | Exceptional heat conductivity for precise temperature control and even cooking, ideal for delicate sauteing tasks. |

| Titanium Saute Pan | Highly durable with excellent non-reactive properties, offering scratch resistance and lightweight ease for high-heat sauteing. |

Material Comparison: Copper vs Titanium Sauté Pans

Copper saute pans offer superior heat conductivity and precise temperature control, making them ideal for delicate cooking tasks. Titanium saute pans provide exceptional durability and non-reactive surfaces, which resist corrosion and ensure longevity.

- Heat Conductivity - Copper pans heat up and cool down faster than titanium, allowing better control over cooking temperature.

- Durability - Titanium pans are highly resistant to scratches and dents, maintaining their structural integrity over time.

- Reactivity - Copper can react with acidic foods, requiring a lining, whereas titanium is non-reactive, preserving food flavor.

Heat Conductivity: Copper and Titanium Performance

Copper saute pans excel in heat conductivity, offering rapid and even heat distribution essential for precise cooking control. Titanium pans, while durable, have significantly lower thermal conductivity, resulting in slower and less uniform heating during sauteing.

- Copper's thermal conductivity - Approximately 400 W/mK enables quick response to temperature changes.

- Titanium's thermal conductivity - Around 20 W/mK limits heat spread, causing uneven cooking surfaces.

- Cooking performance - Copper pans allow for consistent sauteing temperatures, improving food texture and flavor.

Copper saute pans are generally preferred for chefs prioritizing heat precision, while titanium pans are favored for strength and non-reactivity despite their lower heat conductivity.

Temperature Control During Sautéing

Copper saute pans offer superior temperature control due to their excellent thermal conductivity, allowing for rapid heat adjustments during cooking. Titanium pans, while durable and lightweight, do not conduct heat as efficiently, potentially resulting in less precise temperature management.

Precise temperature control is critical for sauteing, as it ensures even cooking and prevents food from sticking or burning. Copper pans heat up quickly and cool down just as fast, giving chefs the ability to react instantly to temperature changes. Titanium pans retain heat longer, which can cause uneven cooking or overheating if not carefully monitored.

Weight and Handling: Ergonomics in Sautéing

Copper saute pans are heavier and provide excellent heat conductivity but may cause wrist fatigue during prolonged cooking sessions. Titanium pans are noticeably lighter, enhancing maneuverability and reducing strain for ergonomic sauteing.

- Copper pans offer superior heat distribution - Heavy construction can make handling cumbersome over time.

- Titanium pans are lightweight - Easier to lift and toss ingredients with minimal effort.

- Ergonomics favors titanium - Reduced weight improves control and decreases fatigue during extensive sauteing.

Durability and Longevity: Copper vs Titanium

Copper saute pans offer excellent heat conductivity but are prone to tarnishing and require regular maintenance to maintain their appearance and performance. Titanium pans are highly durable, resistant to scratches, corrosion, and warping, making them ideal for long-term use with minimal upkeep. For longevity and durability in sauteing, titanium pans generally outperform copper, especially in everyday kitchen environments.

Reactivity with Food: Safety and Flavors

Copper saute pans offer excellent heat conductivity but can react with acidic foods, potentially altering flavors and posing safety concerns if not lined properly with stainless steel. Titanium pans are inert and non-reactive, ensuring that food flavors remain pure and safe during cooking.

Using a copper pan requires careful maintenance to avoid leaching metals into dishes, which might affect both taste and health. Titanium pans provide a durable, safe surface that resists corrosion and maintains the integrity of sauteed ingredients.

Maintenance and Cleaning Requirements

Copper saute pans require regular polishing to prevent tarnish and maintain their characteristic shine, as well as thorough drying to avoid corrosion. Their reactive surface also demands careful cleaning with mild detergents to preserve the metal's integrity.

Titanium pans feature a non-reactive, durable surface that simplifies maintenance, often needing only gentle washing without abrasive scrubbing. Their corrosion resistance and non-stick properties reduce the effort required for cleaning, offering greater convenience for frequent sauteing.

Price and Value: Investment Worthiness

Copper saute pans typically command higher prices due to their superior heat conductivity and aesthetic appeal, making them a premium investment for serious chefs. Titanium pans, while generally more affordable, offer remarkable durability and non-reactive properties, presenting excellent value for everyday cooking. Choosing between them depends on budget constraints and long-term usage priorities, with copper suited for precision cooking and titanium for practical, cost-effective performance.

Related Important Terms

Thermal conductivity gradient

Copper saute pans offer superior thermal conductivity with a gradient of about 400 W/m*K, enabling rapid and even heat distribution for precise sauteing control. Titanium pans have lower thermal conductivity, around 22 W/m*K, resulting in slower heat transfer and less responsive temperature adjustments during cooking.

Rapid heat response

Copper saute pans offer superior rapid heat response due to their excellent thermal conductivity, allowing precise temperature control during cooking. Titanium pans heat more slowly and retain heat longer, making them less responsive to quick temperature adjustments essential for sauteing.

Micro-searing edge control

Copper saute pans provide superior micro-searing edge control due to their exceptional thermal conductivity, allowing precise temperature adjustments that prevent food from sticking or burning. In contrast, titanium pans offer durability and scratch resistance but heat less evenly, making fine temperature management for delicate micro-searing more challenging.

Non-reactive titanium layer

Copper saute pans offer superior heat conductivity for precise temperature control, while titanium pans feature a non-reactive titanium layer that prevents food from reacting with the metal, ensuring flavor integrity and durability during high-heat sauteing. The non-reactive titanium surface also provides excellent resistance to scratching and corrosion, making titanium pans ideal for cooking acidic or delicate ingredients without altering taste.

Molecular caramelization rate

Copper saute pans provide superior thermal conductivity, enabling precise temperature control that enhances molecular caramelization rates for optimal browning and flavor development. Titanium pans, while durable and resistant to corrosion, offer less efficient heat distribution, potentially resulting in slower caramelization and uneven sauteing outcomes.

Copper core induction adaptability

Copper core induction saute pans offer superior thermal conductivity and precise temperature control essential for perfect sauteing, outperforming titanium pans that, while lightweight and durable, lack the efficient heat responsiveness of copper. The copper core ensures rapid, even heat distribution on induction cooktops, preventing hotspots and enabling consistent browning and searing results.

Weight-to-control ratio

Copper saute pans offer excellent heat conductivity and precise temperature control but tend to be heavier, which can reduce maneuverability during sauteing. Titanium pans provide a significantly lighter weight while maintaining durability, enhancing the weight-to-control ratio and allowing for better handling and quicker wrist movements.

Patina development spectrum

Copper saute pans develop a natural patina over time that enhances their heat conductivity and adds a unique, non-stick surface ideal for precise sauteing techniques. Titanium pans, however, resist patina formation, offering a durable, scratch-resistant surface that maintains consistent heat distribution without the seasoning benefits copper provides.

Allergen-neutral coating (titanium)

Titanium saute pans feature an allergen-neutral coating that prevents reactions for sensitive cooks, unlike some copper pans which may have coatings containing allergens or metal residues. This makes titanium pans especially suitable for kitchens requiring hypoallergenic cookware while ensuring even heat distribution and durability for sauteing.

Copper sauté pan vs titanium pan for sautéing. Infographic

cookingdiff.com

cookingdiff.com