Simmering stocks on the stovetop allows for gradual flavor extraction through gentle heat, but maintaining a consistent temperature can be challenging. A thermal circulator offers precise temperature control and even heat distribution, resulting in perfectly clear and flavorful stocks without overcooking. Choosing between simmering and using a thermal circulator depends on the desired consistency and level of control in the cooking process.

Table of Comparison

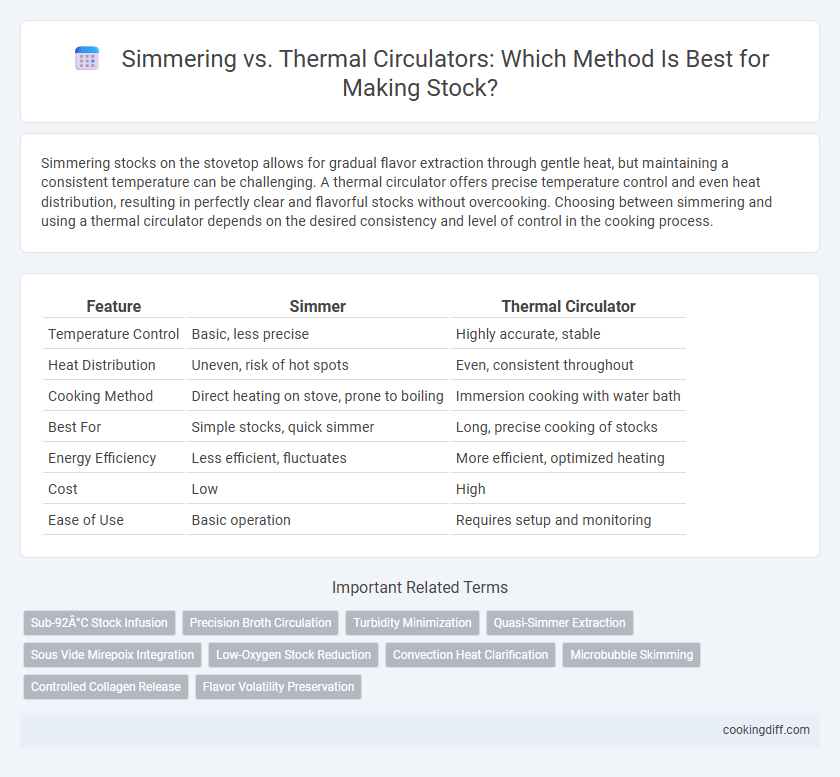

| Feature | Simmer | Thermal Circulator |

|---|---|---|

| Temperature Control | Basic, less precise | Highly accurate, stable |

| Heat Distribution | Uneven, risk of hot spots | Even, consistent throughout |

| Cooking Method | Direct heating on stove, prone to boiling | Immersion cooking with water bath |

| Best For | Simple stocks, quick simmer | Long, precise cooking of stocks |

| Energy Efficiency | Less efficient, fluctuates | More efficient, optimized heating |

| Cost | Low | High |

| Ease of Use | Basic operation | Requires setup and monitoring |

Simmering and Thermal Circulators: An Overview

Simmering involves maintaining a liquid just below boiling point, typically around 185degF to 205degF, ideal for gently cooking stocks without breaking down delicate flavors. Thermal circulators, often used in sous-vide cooking, provide precise temperature control and consistent water circulation to evenly heat stocks over extended periods.

Thermal circulators enhance simmering by stabilizing temperature and preventing hot spots, ensuring thorough extraction of flavors from bones and vegetables. While traditional simmering relies on stovetop heat variability, thermal circulators deliver accuracy and efficiency for high-quality, clear stocks.

How Simmering Affects Stock Flavor and Clarity

Simmering stocks at a low, consistent temperature helps extract deep flavors while preventing emulsification of fats, resulting in a clearer broth. A thermal circulator maintains precise temperature control, minimizing agitation and preserving the stock's clarity and purity of taste. Using a simmer method without precise temperature control can lead to cloudy stocks due to excessive boiling and agitation of particles.

Precision Temperature Control: Thermal Circulator Advantages

Simmering stocks with a thermal circulator offers superior precision temperature control compared to traditional simmer methods, ensuring consistent heat distribution. This precision prevents overcooking and maintains the delicate flavors and nutrients in stocks.

- Consistent Temperature - Thermal circulators maintain exact temperatures, avoiding fluctuations common with stovetop simmering.

- Improved Flavor Extraction - Stable heat enhances the extraction of flavors from bones and vegetables without overheating.

- Energy Efficiency - Thermal circulators use less energy by sustaining a uniform temperature throughout the cooking process.

Equipment Needed for Each Method

Simmering stocks typically requires basic kitchen equipment, while thermal circulators involve specialized devices for precise temperature control. Each method's equipment influences cooking consistency and ease.

- Simmering Pot - A heavy-bottomed pot is essential to maintain even heat and prevent scorching during stock simmering.

- Stove or Heat Source - Conventional gas or electric stoves provide the controlled heat necessary for simmering.

- Thermal Circulator - This precision device circulates water at exact temperatures, ideal for maintaining consistent stock temperature over long periods.

Comparing Energy Efficiency: Simmering vs Circulator

Which method offers better energy efficiency for maintaining stocks: simmering on a stove or using a thermal circulator? Simmering often consumes more energy due to heat loss and continual temperature adjustments, whereas thermal circulators maintain precise temperatures with minimal energy waste. Thermal circulators optimize power usage by circulating water evenly, reducing the energy needed to keep stocks at a consistent simmering temperature.

Hands-on Involvement: Active vs Passive Cooking

Simmering stocks requires hands-on involvement with constant monitoring and manual temperature adjustments to maintain a gentle heat without boiling. This active cooking method allows for real-time control over flavor extraction but demands attention to avoid overcooking or evaporation.

Thermal circulators provide a passive cooking experience by maintaining a precise, consistent temperature throughout the stock without user intervention. This method minimizes the risk of temperature fluctuations, ensuring even heat distribution and a controlled simmer with less hands-on effort.

Stock Consistency: Visual and Taste Differences

Simmering stocks by traditional methods often results in variable temperature control, which can affect both the visual clarity and flavor depth of the stock. Thermal circulators provide precise temperature regulation, promoting consistent extraction of flavors and maintaining a clearer broth throughout the cooking process.

- Simmering Variability - Fluctuating heat levels cause uneven flavor extraction and potential cloudiness in the stock.

- Thermal Circulator Control - Maintains stable temperatures that enhance the clarity and balanced taste of the stock.

- Flavor Consistency - Thermal circulators produce repeatable results, ensuring each batch of stock retains the same rich quality.

Choosing a thermal circulator over traditional simmering significantly improves stock consistency in both appearance and flavor profile.

Time Requirements for Simmering and Circulator Stocks

Simmering stocks typically requires maintaining a gentle heat for 2 to 4 hours to extract deep flavors while preventing cloudiness. Thermal circulators offer precise temperature control, allowing stocks to be cooked evenly and efficiently, often reducing the time to about 1.5 to 3 hours. This method minimizes the risk of overcooking and preserves delicate aromatics, resulting in a clearer, richer stock.

Ideal Applications: When to Choose Simmering or Circulator

| Simmering | Ideal for gentle heat applications like traditional stock preparation where slow evaporation and gradual flavor extraction are essential. Maintains liquid temperatures just below boiling (around 185degF to 205degF), which prevents cloudiness and preserves clarity in stocks and broths. |

| Thermal Circulator | Best suited for precise temperature control and uniform heat distribution, essential when cooking stocks requiring consistent low-temperature infusion over extended periods. Enables exact temperature settings (within +-0.1degF) to avoid scorching and optimize collagen breakdown in meat and bones for richer stock quality. |

Related Important Terms

Sub-92°C Stock Infusion

Simmering at sub-92degC allows gentle stock infusion, preserving delicate flavors and preventing unwanted cloudiness often caused by higher temperatures. Thermal circulators provide precise temperature control below 92degC, ensuring consistent heat distribution and optimal extraction of essences from ingredients during the infusion process.

Precision Broth Circulation

A thermal circulator offers superior precision in maintaining consistent temperatures for simmering stocks, ensuring uniform broth circulation and preventing hot spots or uneven cooking. In contrast, traditional simmer methods often fluctuate in temperature, resulting in less efficient heat distribution and potential flavor inconsistencies in the stock.

Turbidity Minimization

Simmering stocks maintains gentle heat to reduce agitation, minimizing turbidity by preventing protein particle disruption. Thermal circulators provide precise temperature control and consistent water movement, further reducing cloudiness in stocks by evenly distributing heat without vigorous bubbling.

Quasi-Simmer Extraction

Simmering stock involves maintaining a temperature just below boiling, typically around 185degF to 205degF, which extracts flavors gently without emulsifying fats or breaking down delicate ingredients. Quasi-simmer extraction with a thermal circulator allows precise temperature control, ensuring consistent low heat infusion that preserves clarity and depth in stocks better than traditional simmering methods.

Sous Vide Mirepoix Integration

Simmering stocks using a traditional stovetop method can lead to uneven temperature control, resulting in inconsistent extraction of flavors from the mirepoix, whereas a thermal circulator maintains a precise, stable temperature ideal for sous vide mirepoix integration. Thermal circulators enhance the infusion process by evenly circulating heat, optimizing the breakdown of aromatic vegetables and yielding a more balanced, richly-flavored stock.

Low-Oxygen Stock Reduction

Simmering offers gentle heat control that preserves flavor but struggles with maintaining consistent low-oxygen environments, leading to higher oxidation in stocks. Thermal circulators provide precise temperature regulation and continuous water circulation, significantly reducing oxygen exposure and enhancing stock clarity and depth.

Convection Heat Clarification

Simmering provides gentle heat that prevents agitation while maintaining flavor clarity in stocks, but a thermal circulator ensures precise temperature control and uniform convection heat distribution for optimal clarification. The steady, controlled convection of a thermal circulator minimizes impurities and results in a clearer, cleaner stock compared to traditional simmering methods.

Microbubble Skimming

Simmering stocks with a thermal circulator offers precise temperature control, ensuring consistent heat levels ideal for microbubble skimming, which effectively removes impurities and enhances stock clarity. Unlike traditional simmering methods, thermal circulators maintain steady microbubble formation without excessive agitation, optimizing the skimming process for a cleaner, more refined stock.

Controlled Collagen Release

Simmering stocks provides gentle heat that slowly extracts collagen, but thermal circulators offer precise temperature control for optimal collagen breakdown without overcooking. Controlled collagen release with thermal circulators enhances stock clarity and mouthfeel by maintaining consistent low temperatures around 85-90degC.

Simmer vs Thermal Circulator for stocks. Infographic

cookingdiff.com

cookingdiff.com