Conventional vacuum sealers use external suction to remove air from flexible bags, making them ideal for vacuum sealing flat items but less effective with liquids or thick cuts. Chamber vacuum sealers create a vacuum inside a sealed chamber, ensuring more efficient air removal and preventing liquid from being drawn out, which is crucial for maintaining the perfect sous vide environment for pet food. This technology provides a more reliable seal and extends shelf life by minimizing air exposure and oxidation for pet meals.

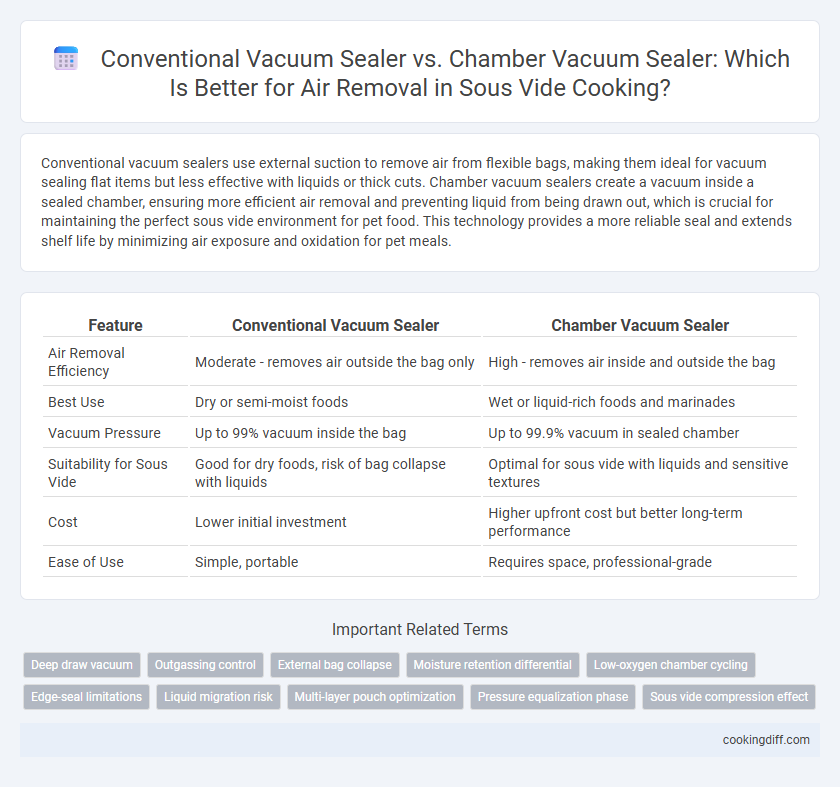

Table of Comparison

| Feature | Conventional Vacuum Sealer | Chamber Vacuum Sealer |

|---|---|---|

| Air Removal Efficiency | Moderate - removes air outside the bag only | High - removes air inside and outside the bag |

| Best Use | Dry or semi-moist foods | Wet or liquid-rich foods and marinades |

| Vacuum Pressure | Up to 99% vacuum inside the bag | Up to 99.9% vacuum in sealed chamber |

| Suitability for Sous Vide | Good for dry foods, risk of bag collapse with liquids | Optimal for sous vide with liquids and sensitive textures |

| Cost | Lower initial investment | Higher upfront cost but better long-term performance |

| Ease of Use | Simple, portable | Requires space, professional-grade |

Understanding Vacuum Sealers: Conventional vs Chamber

Conventional vacuum sealers use external suction to remove air, suitable for dry foods but less effective for liquids or moist items due to potential liquid spillover. Chamber vacuum sealers create a vacuum inside a sealed chamber, evenly removing air from bags containing liquids or soft foods.

Chamber vacuum sealers offer stronger, more consistent seals, making them ideal for sous vide cooking where precise air removal prevents bag swelling and ensures even heat transfer. Conventional sealers are more affordable and compact, favored for everyday use with dry ingredients but limited in handling moisture-rich foods.

How Conventional Vacuum Sealers Work

Conventional vacuum sealers remove air by drawing it out through a small nozzle before sealing the bag's open edge. They rely on external vacuum pressure and are most effective with dry foods.

- External suction method - Air is extracted by a vacuum pump located outside the bag, which limits the amount of air removed.

- Seal bar operation - A heated seal bar melts the bag edges to create an airtight closure immediately after air removal.

- Limitations with liquids - These sealers struggle with wet or liquid-rich foods as moisture can interfere with the vacuum and sealing process.

Conventional vacuum sealers are cost-efficient but less versatile compared to chamber vacuum sealers when it comes to complete air removal for sous vide cooking.

How Chamber Vacuum Sealers Operate

Chamber vacuum sealers create a vacuum by removing air from an entire sealed chamber, allowing uniform pressure reduction around the food item. This method efficiently removes air even from liquids, making it ideal for sous vide cooking where precise vacuum levels enhance cooking consistency.

- Air Removal Process - Chamber vacuum sealers evacuate air from both inside the bag and the surrounding chamber to create a deep vacuum.

- Consistency - The uniform vacuum environment prevents bag collapse and preserves delicate food textures during sealing.

- Suitability for Liquids - Unlike conventional vacuum sealers, chamber models effectively vacuum seal liquids without drawing them into the machine.

Air Removal Efficiency: Side-by-Side Comparison

Chamber vacuum sealers achieve superior air removal by evacuating air from both the bag and the chamber, ensuring near-complete vacuum levels ideal for sous vide cooking. Conventional vacuum sealers, which only remove air from the bag outside the machine, often leave residual air pockets that can hinder heat transfer and cooking precision. For sous vide applications, chamber vacuum sealers consistently provide better air extraction, enhancing food preservation and cooking consistency.

Impact on Food Texture and Freshness

Conventional vacuum sealers use external suction that can sometimes compress delicate foods, affecting texture and freshness. Chamber vacuum sealers create a uniform vacuum environment that better preserves food integrity by minimizing air exposure and preventing texture damage.

- Conventional vacuum sealers compress food - External suction might crush soft items, leading to texture loss.

- Chamber vacuum sealers ensure even pressure - They maintain the shape and moisture of food by creating a balanced vacuum.

- Impact on freshness - Chamber sealers extend freshness longer by reducing oxygen more effectively than conventional models.

Suitability for Liquid-Rich Foods

Conventional vacuum sealers use external air removal that can struggle with liquid-rich foods, often causing liquids to be sucked into the machine. This makes them less suitable for sous vide cooking of juicy or marinated ingredients.

Chamber vacuum sealers create a vacuum inside the entire chamber, allowing efficient air removal without drawing out liquids. This makes them ideal for sealing soups, sauces, or wet marinades used in sous vide preparation.

Bag Types and Compatibility

Conventional vacuum sealers require specific textured or embossed bags designed to allow air extraction through the channels, limiting compatibility to certain polyethylene or nylon materials. Chamber vacuum sealers accommodate a wider range of bag types, including smooth, non-textured vacuum bags and rolls made from multilayer plastics, providing greater flexibility for sous vide cooking. This compatibility advantage enables chamber sealers to achieve more efficient air removal, especially with liquid-rich foods, enhancing the overall vacuum sealing process.

Speed and Scalability in Sous Vide Prep

| Conventional vacuum sealers use an external suction mechanism, typically removing air slower, making them less efficient for high-volume sous vide meal prep. |

| Chamber vacuum sealers evacuate air inside a sealed chamber, allowing rapid and complete air removal, significantly enhancing speed and scalability in sous vide cooking. |

| Chamber sealers prevent liquid from being sucked out, enabling consistent seal quality when sealing liquids or marinades, ideal for batch sous vide cooking processes. |

Cost Considerations and Investment Value

Conventional vacuum sealers typically cost less upfront, making them a budget-friendly option for home cooks and small-scale sous vide enthusiasts. Chamber vacuum sealers have a higher initial investment but provide superior air removal efficiency, especially for liquids and marinades.

While chamber vacuum sealers demand a larger financial commitment, their durability and ability to maintain optimal vacuum levels offer long-term value for frequent users and professionals. Conventional models may require multiple sealing attempts and are limited by bag thickness, potentially increasing costs over time. Investing in a chamber vacuum sealer enhances precision and food preservation, justifying the higher price for serious sous vide practitioners.

Related Important Terms

Deep draw vacuum

Chamber vacuum sealers provide superior deep draw vacuum capabilities compared to conventional vacuum sealers, effectively removing more air to enhance sous vide cooking precision and food preservation. This stronger vacuum pressure minimizes oxidation and extends shelf life, making chamber sealers the preferred choice for professional-grade sous vide applications.

Outgassing control

Chamber vacuum sealers excel in outgassing control by creating a vacuum within the sealed chamber, effectively removing air and moisture from porous or liquid-rich sous vide bags to prevent cooking inconsistencies. Conventional vacuum sealers struggle with outgassing as they only extract air from the pouch's opening, leading to potential air pockets and uneven heat transfer during sous vide cooking.

External bag collapse

Chamber vacuum sealers create a complete vacuum inside the chamber, effectively collapsing external bags around the food for uniform air removal, essential in sous vide cooking to prevent uneven cooking and bacterial growth. Conventional vacuum sealers often struggle to fully collapse external bags when sealing, leaving residual air pockets that compromise the precision and safety of sous vide results.

Moisture retention differential

Chamber vacuum sealers outperform conventional vacuum sealers in moisture retention by evenly removing air and sealing wet foods without losing juices, preventing moisture loss during sous vide cooking. Conventional vacuum sealers often struggle with liquid extraction, which can compromise texture and flavor due to inconsistent moisture retention.

Low-oxygen chamber cycling

Low-oxygen chamber cycling in chamber vacuum sealers efficiently removes air by equalizing pressure inside the chamber, ensuring consistent and thorough vacuum extraction ideal for sous vide precision. Conventional vacuum sealers rely on external suction, often leaving residual air pockets that compromise airtight seals and sous vide cooking accuracy.

Edge-seal limitations

Conventional vacuum sealers use edge-seal technology that often restricts the vacuum level, leaving residual air pockets that compromise sous vide precision and food safety. Chamber vacuum sealers eliminate edge-seal limitations by uniformly removing air inside the entire bag, resulting in superior vacuum strength and consistent cooking results.

Liquid migration risk

Chamber vacuum sealers effectively minimize liquid migration by equalizing pressure inside the chamber, allowing for safe vacuum extraction of liquids and marinades without bag collapse. Conventional vacuum sealers pose a higher risk of liquid migration as the external suction can cause liquid to be drawn into the vacuum pump, potentially damaging the machine and compromising the seal.

Multi-layer pouch optimization

Chamber vacuum sealers provide superior air removal by evenly extracting air from multi-layer pouches, ensuring a consistent seal without pouch collapse. Conventional vacuum sealers may struggle with multi-layer materials, risking incomplete air removal and compromised seal integrity during sous vide cooking.

Pressure equalization phase

Conventional vacuum sealers rely on external air suction, which limits pressure equalization during sealing and can leave residual air pockets in unevenly shaped bags. Chamber vacuum sealers perform pressure equalization by evacuating air from both inside and outside the bag within a sealed chamber, ensuring more consistent vacuum levels and superior air removal for precise sous vide cooking.

Conventional vacuum sealer vs chamber vacuum sealer for air removal. Infographic

cookingdiff.com

cookingdiff.com