Sous vide cooking offers precise temperature control, ensuring consistent flavor development by slowly infusing ingredients without risk of overcooking. In-bag fermentation relies on microbial activity to develop complex flavors but can be less predictable and requires careful monitoring to avoid spoilage. Combining sous vide with in-bag fermentation allows chefs to harness controlled enzymatic reactions alongside microorganism-driven flavor enhancement for unique culinary results.

Table of Comparison

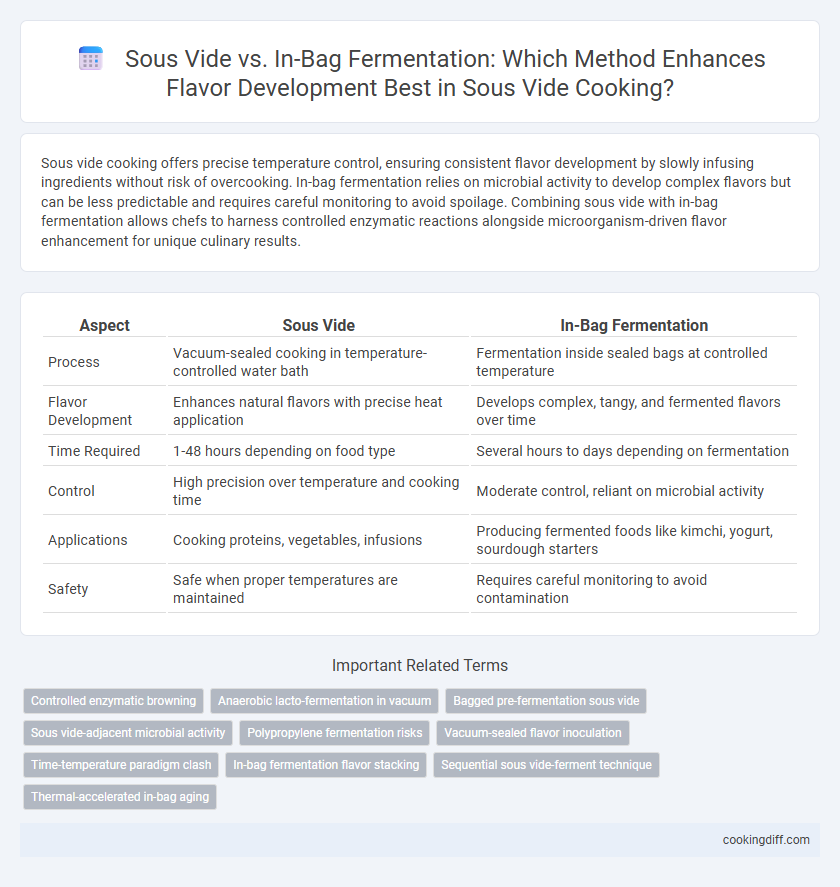

| Aspect | Sous Vide | In-Bag Fermentation |

|---|---|---|

| Process | Vacuum-sealed cooking in temperature-controlled water bath | Fermentation inside sealed bags at controlled temperature |

| Flavor Development | Enhances natural flavors with precise heat application | Develops complex, tangy, and fermented flavors over time |

| Time Required | 1-48 hours depending on food type | Several hours to days depending on fermentation |

| Control | High precision over temperature and cooking time | Moderate control, reliant on microbial activity |

| Applications | Cooking proteins, vegetables, infusions | Producing fermented foods like kimchi, yogurt, sourdough starters |

| Safety | Safe when proper temperatures are maintained | Requires careful monitoring to avoid contamination |

Introduction to Flavor Development in Cooking

Flavor development in cooking relies on precise temperature control and time to enhance natural taste profiles. Sous vide and in-bag fermentation each use unique methods to intensify umami and complex flavors through different chemical processes.

- Sous vide enhances flavor - It uses low-temperature, controlled cooking to preserve and concentrate natural juices and aromas in food.

- In-bag fermentation transforms flavor - Fermentation introduces beneficial microbes that create unique acids and compounds, altering taste and texture.

- Temperature precision impacts outcomes - Sous vide maintains exact heat levels to prevent overcooking, while fermentation relies on room temperature conditions for microbial activity.

Understanding Sous Vide: Basics and Applications

Sous vide cooking involves vacuum-sealing food and cooking it at precise, low temperatures to enhance flavor development and texture. Unlike in-bag fermentation, which relies on microbial activity to create complex flavors over time, sous vide offers consistent results through controlled heat application. This technique is widely used for meats, vegetables, and even eggs to achieve optimal doneness and intensified natural flavors.

What is In-Bag Fermentation?

In-bag fermentation is a culinary technique where ingredients are sealed in airtight bags to undergo controlled fermentation, enhancing complex flavors and textures. Unlike sous vide, which uses precise temperature water baths for cooking, in-bag fermentation relies on natural microbial activity within the sealed environment to develop unique tastes. This method is popular for fermenting vegetables, dairy, and proteins, offering a distinct flavor profile through anaerobic fermentation processes.

Key Differences Between Sous Vide and In-Bag Fermentation

Sous vide uses precise temperature control with water immersion to evenly cook food and enhance its natural flavors through consistent heat exposure. In contrast, in-bag fermentation relies on microbial activity within a sealed environment to develop complex flavors over time through fermentation processes.

Sous vide shortens flavor development by cooking foods at steady temperatures, ensuring reproducibility and texture control. In-bag fermentation takes longer, promoting biochemical changes and the growth of beneficial bacteria, resulting in distinct taste profiles unique to fermentation.

Temperature Control and Its Impact on Flavor

Sous vide cooking offers precise temperature control within +-0.1degC, enabling consistent flavor development by maintaining optimal enzymatic activity. This precise regulation prevents overcooking and preserves delicate flavor compounds that are often lost in traditional fermentation.

In contrast, in-bag fermentation relies on ambient temperature fluctuations, which can lead to inconsistent flavor profiles due to variable microbial activity. The lack of precise temperature control may result in uneven fermentation and unpredictable sourness or aroma intensity.

Microbial Activity: Safety and Flavor Profiles

Sous vide cooking uses precise temperature control to limit microbial growth, enhancing safety while developing subtle flavor profiles without fermentation. In-bag fermentation promotes diverse microbial activity, generating complex flavors but requires careful monitoring to prevent harmful contamination.

- Controlled Environment - Sous vide maintains temperatures typically between 55degC and 65degC, inhibiting pathogenic bacteria while supporting enzymatic reactions that develop flavor.

- Microbial Diversity - In-bag fermentation encourages beneficial microbes like Lactobacillus species, which produce acids and aroma compounds contributing to rich, tangy flavors.

- Safety Risks - Sous vide reduces food safety risks due to precise thermal regulation, whereas in-bag fermentation must manage variables like temperature and oxygen exposure to avoid spoilage.

Texture Changes: Sous Vide vs. Fermentation

How do texture changes compare between sous vide cooking and in-bag fermentation for flavor development? Sous vide uses precise temperature control to achieve consistent tenderness by breaking down connective tissues without overcooking, resulting in a smooth, uniform texture. In-bag fermentation alters texture through enzymatic activity and microbial metabolism, often producing a more complex, slightly chewy or tenderized feel depending on fermentation duration and conditions.

Ingredient Suitability for Each Method

| Ingredient Suitability | Sous Vide | In-Bag Fermentation |

| Protein Foods | Highly compatible with meats, poultry, and fish for precise temperature control enhancing tenderness and flavor infusion. | Limited suitability due to moisture and temperature constraints affecting protein texture and microbial growth. |

| Vegetables | Ideal for delicate vegetables, allowing consistent cooking without nutrient loss or flavor degradation. | Effective for fermentable vegetables like cabbage or cucumbers requiring anaerobic conditions for lactic acid bacteria development. |

| Fermentation Precursors | Not designed to support microbial activity; flavors develop primarily through controlled cooking reactions. | Specifically suitable for ingredients requiring natural fermentation processes, promoting complex flavor profiles and probiotic benefits. |

Culinary Outcomes: Pros and Cons Compared

Sous vide cooking uses precise temperature control to enhance flavors by evenly cooking proteins and preserving natural juices, while in-bag fermentation develops complex flavors through microbial activity over time. Both methods emphasize flavor development but differ in texture outcomes and preparation duration.

- Sous vide - Offers consistent texture and intensifies natural flavors by maintaining exact temperature control.

- In-bag fermentation - Creates unique, tangy flavors through controlled microbial growth and enzymatic activity.

- Preparation time - Sous vide requires hours at specific temperatures, whereas fermentation can take days to weeks for full flavor maturation.

Choosing between sous vide and in-bag fermentation depends on desired flavor complexity and time availability in culinary applications.

Related Important Terms

Controlled enzymatic browning

Sous vide cooking offers precise temperature control that inhibits uncontrolled enzymatic browning, preserving the natural flavors and textures of ingredients. In contrast, in-bag fermentation relies on enzymatic activity within a sealed environment, promoting complex flavor development through controlled browning and microbial actions.

Anaerobic lacto-fermentation in vacuum

Sous vide cooking enhances anaerobic lacto-fermentation by maintaining a consistent vacuum-sealed environment, optimizing microbial activity to intensify flavor development in foods. In-bag fermentation also relies on anaerobic conditions but lacks precise temperature control, resulting in less predictable flavor profiles compared to sous vide techniques.

Bagged pre-fermentation sous vide

Bagged pre-fermentation sous vide enhances flavor development by precisely controlling temperature and fermentation time, resulting in consistent and intensified taste profiles. This method minimizes oxygen exposure compared to traditional in-bag fermentation, reducing spoilage risk and preserving desirable aromatic compounds.

Sous vide-adjacent microbial activity

Sous vide precisely controls temperature to promote selective microbial activity that enhances umami and complex flavor compounds while minimizing spoilage bacteria growth. In contrast, in-bag fermentation relies on naturally occurring microbes without temperature stabilization, resulting in more variable but potentially stronger flavor profiles.

Polypropylene fermentation risks

Sous vide cooking offers precise temperature control that minimizes the risk of harmful microbial growth, unlike in-bag fermentation which often uses polypropylene bags prone to chemical leaching and contamination. Polypropylene fermentation risks include potential migration of plasticizers and toxins into food, compromising flavor integrity and posing health hazards during extended fermentation periods.

Vacuum-sealed flavor inoculation

Vacuum-sealed flavor inoculation in sous vide enhances precise control over fermentation conditions, promoting uniform microbial activity and consistent flavor profiles compared to in-bag fermentation methods. The sous vide technique maintains optimal temperature stability, accelerating biochemical reactions and intensifying complex flavor compounds while reducing oxidation and contamination risks.

Time-temperature paradigm clash

Sous vide utilizes precise temperature control for extended periods, typically between 55degC to 65degC, to enhance flavor by slowly breaking down proteins and fats, while in-bag fermentation relies on microbial activity within anaerobic conditions at lower temperatures, usually around 20degC to 30degC, to develop complex flavor profiles through organic acid production. The time-temperature paradigm clash lies in sous vide's thermal consistency accelerating enzymatic reactions versus fermentation's biological processes requiring time at sub-pasteurization temperatures, creating distinct flavor pathways unique to each method.

In-bag fermentation flavor stacking

In-bag fermentation excels at flavor stacking by allowing complex microbial activity that enhances umami, tangy, and fruity notes through natural fermentation processes inside the sealed environment. Sous vide, while precise in temperature control, primarily focuses on texture and tenderness rather than developing layered fermented flavors.

Sequential sous vide-ferment technique

The sequential sous vide-ferment technique enhances flavor development by precisely controlling temperature during sous vide cooking followed by in-bag fermentation, allowing enzymes and microbes to synergistically intensify umami and complexity. This method optimizes Maillard reactions during sous vide and promotes probiotic growth during fermentation, resulting in deeply layered, tender textures and nuanced taste profiles unmatched by either technique alone.

Sous vide vs In-bag fermentation for flavor development. Infographic

cookingdiff.com

cookingdiff.com