Sous vide offers precise temperature control for cooking, ensuring food safety by maintaining temperatures that eliminate pathogens without overcooking. Pressure-assisted thermal processing uses high pressure combined with heat to inactivate microorganisms more rapidly, enhancing safety for low-acid foods. Both methods improve food safety but differ in processing time, texture preservation, and equipment complexity.

Table of Comparison

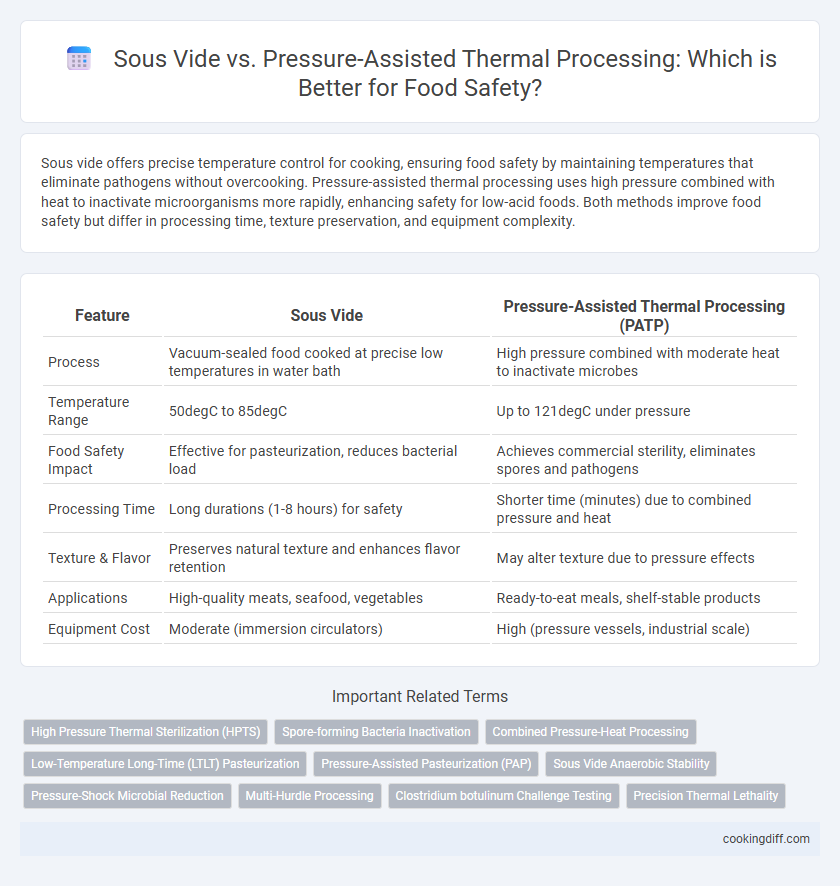

| Feature | Sous Vide | Pressure-Assisted Thermal Processing (PATP) |

|---|---|---|

| Process | Vacuum-sealed food cooked at precise low temperatures in water bath | High pressure combined with moderate heat to inactivate microbes |

| Temperature Range | 50degC to 85degC | Up to 121degC under pressure |

| Food Safety Impact | Effective for pasteurization, reduces bacterial load | Achieves commercial sterility, eliminates spores and pathogens |

| Processing Time | Long durations (1-8 hours) for safety | Shorter time (minutes) due to combined pressure and heat |

| Texture & Flavor | Preserves natural texture and enhances flavor retention | May alter texture due to pressure effects |

| Applications | High-quality meats, seafood, vegetables | Ready-to-eat meals, shelf-stable products |

| Equipment Cost | Moderate (immersion circulators) | High (pressure vessels, industrial scale) |

Introduction to Sous Vide and Pressure-Assisted Thermal Processing

Sous vide is a cooking method that involves vacuum-sealing food and cooking it at precise, low temperatures for extended periods to ensure even cooking and enhanced flavor retention. Pressure-assisted thermal processing (PATP) uses high pressure combined with moderate heat to inactivate pathogens and extend shelf life while preserving food quality. Both technologies prioritize food safety by targeting microbial inactivation but differ in temperature, pressure application, and processing times.

Principles and Mechanisms of Sous Vide Cooking

Sous vide cooking operates by vacuum-sealing food and cooking it at precise, low temperatures for extended periods, ensuring even heat distribution and retaining moisture. This method inactivates pathogens through controlled thermal exposure without compromising food texture or flavor.

Pressure-assisted thermal processing, by contrast, combines elevated pressure with heat to accelerate microbial inactivation and preserve nutrients. Sous vide relies mainly on temperature and time to achieve food safety, emphasizing gentle cooking mechanisms over high-pressure effects.

Understanding Pressure-Assisted Thermal Processing (PATP)

Pressure-Assisted Thermal Processing (PATP) combines high pressure and elevated temperature to inactivate pathogens in food, enhancing microbial safety while preserving quality. Unlike traditional heat-based methods, PATP applies pressures up to 600 MPa, allowing sterilization at lower temperatures and shorter times. This technique is effective against bacterial spores, making it a valuable alternative or complement to sous vide cooking for ensuring safe, shelf-stable products.

Food Safety Standards: Sous Vide vs. PATP

Sous vide cooking maintains food safety by precisely controlling temperature and time, effectively eliminating pathogens without overcooking. The method relies on FDA guidelines recommending temperatures above 131degF for specific durations to inhibit bacterial growth.

Pressure-Assisted Thermal Processing (PATP) enhances food safety by combining high pressure and heat, allowing sterilization at lower temperatures and shorter times. PATP meets USDA and FDA standards for commercial sterile processing, offering a higher assurance level against spore-forming bacteria compared to sous vide.

Microbial Reduction Efficiency in Sous Vide and PATP

Sous vide cooking achieves microbial reduction by maintaining precise temperature control, typically between 55degC and 65degC, for extended periods, effectively targeting pathogens like Listeria monocytogenes and Salmonella spp. Pressure-assisted thermal processing (PATP) enhances microbial inactivation by combining high pressure (up to 600 MPa) with moderate heat (90degC to 121degC), offering a significantly faster reduction of bacterial spores and vegetative cells.

The microbial reduction efficiency of sous vide depends on time-temperature combinations, requiring longer cooking durations to ensure safety, especially against spore-forming bacteria. PATP provides superior inactivation rates due to synergistic effects of pressure and heat, enabling reduced thermal damage to food quality while achieving sterilization. Both methods contribute to food safety, but PATP is particularly advantageous for high-acid and low-acid foods requiring stringent microbial control.

Nutrient Retention and Quality Comparison

| Processing Method | Nutrient Retention | Food Quality |

|---|---|---|

| Sous Vide | High retention of vitamins and antioxidants due to low-temperature, precise cooking. | Maintains texture, flavor, and moisture, resulting in superior sensory attributes. |

| Pressure-Assisted Thermal Processing | Moderate nutrient loss mainly of heat-sensitive vitamins due to high temperature and pressure. | Texture may be altered; potential for nutrient leaching and flavor degradation occurs with intense processing. |

Risk Management: Pathogens and Contamination Control

Sous vide cooking and pressure-assisted thermal processing (PATP) both aim to enhance food safety by controlling pathogens and contamination, yet they operate through different mechanisms and risk management strategies. Sous vide relies on precise temperature control to minimize microbial growth, while PATP combines pressure and heat to achieve more rapid inactivation of resistant pathogens.

- Pathogen Inactivation - PATP uses elevated pressure and temperature, enabling faster destruction of pathogens like Clostridium botulinum compared to sous vide.

- Contamination Control - Sous vide employs vacuum sealing to limit oxygen exposure, reducing aerobic spoilage microorganisms and contamination risk.

- Temperature Precision - Sous vide's strict temperature control minimizes overcooking while ensuring safety, but may require longer processing times than PATP.

Effective risk management for food safety depends on choosing the appropriate technology based on pathogen resistance and processing goals.

Industrial Applications: Sous Vide vs. PATP

Industrial applications of sous vide provide precise temperature control to ensure consistent food safety while preserving quality. Pressure-assisted thermal processing (PATP) combines pressure and heat to inactivate pathogens rapidly, offering faster sterilization in comparison.

- Sous Vide Precision - Sous vide uses controlled low temperatures over extended times to achieve pasteurization without compromising texture or nutrients.

- PATP Efficiency - PATP applies high pressure and moderate heat simultaneously, significantly reducing processing time for shelf-stable foods.

- Food Safety Impact - Both methods enhance microbial inactivation, but PATP better suits industrial scale with higher throughput and improved sterilization efficacy.

Regulatory Guidelines and Compliance Requirements

How do regulatory guidelines differ between sous vide and pressure-assisted thermal processing in ensuring food safety? Sous vide requires strict time-temperature controls to prevent pathogens, with agencies like the USDA providing specific standards for vacuum-sealed cooking. Pressure-assisted thermal processing mandates compliance with FDA regulations for commercial sterilization, ensuring microbial inactivation under pressure, which is essential for low-acid foods.

Related Important Terms

High Pressure Thermal Sterilization (HPTS)

High Pressure Thermal Sterilization (HPTS) combines elevated pressure and temperature to inactivate pathogens more efficiently than traditional sous vide, ensuring enhanced food safety and extended shelf life. Unlike sous vide's precise temperature control for texture and flavor, HPTS delivers commercial sterility by disrupting microbial cells under pressure, making it a superior method for sterilizing ready-to-eat meals.

Spore-forming Bacteria Inactivation

Sous vide cooking at controlled temperatures effectively inactivates vegetative bacteria but often falls short against heat-resistant spore-forming bacteria such as Clostridium botulinum. Pressure-assisted thermal processing (PATP) combines elevated pressure and temperature, significantly enhancing spore inactivation rates and ensuring superior food safety compared to traditional sous vide methods.

Combined Pressure-Heat Processing

Combined pressure-heat processing in sous vide enhances microbial inactivation by applying precise temperature control alongside elevated pressure, which disrupts cellular structures more effectively than conventional thermal methods alone. This synergy accelerates pathogen destruction, improves food safety, and preserves sensory qualities better than pressure-assisted thermal processing or traditional sous vide techniques individually.

Low-Temperature Long-Time (LTLT) Pasteurization

Low-Temperature Long-Time (LTLT) pasteurization in sous vide cooking ensures precise temperature control to inactivate pathogens while preserving food quality, contrasting with pressure-assisted thermal processing that uses high pressure and temperature for rapid microbial inactivation but may alter texture. LTLT sous vide offers enhanced safety for vacuum-sealed foods by maintaining consistent temperatures, minimizing nutrient loss, and reducing overcooking risks compared to pressure-based methods.

Pressure-Assisted Pasteurization (PAP)

Pressure-Assisted Pasteurization (PAP) combines high pressure and moderate heat to effectively inactivate pathogens while preserving food texture and nutrition, offering a faster alternative to traditional sous vide cooking. PAP achieves enhanced food safety with reduced thermal exposure, minimizing quality loss compared to conventional sous vide methods.

Sous Vide Anaerobic Stability

Sous vide cooking ensures anaerobic stability by precisely controlling low temperatures and vacuum-sealed environments, inhibiting the growth of anaerobic pathogens like Clostridium botulinum. Unlike pressure-assisted thermal processing, which relies on high pressure and temperature, sous vide maintains food safety through extended cooking times and strict oxygen exclusion, optimizing both texture and microbial safety.

Pressure-Shock Microbial Reduction

Pressure-shock microbial reduction in pressure-assisted thermal processing (PATP) leverages high pressure and moderate heat to inactivate pathogens more rapidly than sous vide, enhancing food safety without compromising texture. This method achieves superior microbial kill rates by disrupting cellular structures more effectively than the low-temperature, long-time approach of sous vide cooking.

Multi-Hurdle Processing

Multi-hurdle processing combining sous vide and pressure-assisted thermal processing enhances food safety by integrating precise temperature control with high-pressure inactivation of pathogens, effectively reducing spoilage microorganisms and toxin formation. This synergistic approach extends shelf life while preserving sensory and nutritional quality, outperforming either method used independently.

Clostridium botulinum Challenge Testing

Sous vide cooking relies on precise temperature control to inactivate Clostridium botulinum, but pressure-assisted thermal processing (PATP) offers enhanced microbial inactivation by combining high pressure and heat, reducing spore survival more effectively. Clostridium botulinum challenge testing shows PATP achieves faster and more reliable spore destruction compared to traditional sous vide, improving food safety in low-acid, vacuum-sealed products.

Sous vide vs pressure-assisted thermal processing for food safety. Infographic

cookingdiff.com

cookingdiff.com