Sous vide cooking ensures precise temperature control and even doneness, while rapid nitrogen chilling quickly cools the food to preserve texture before searing. Rapid nitrogen chilling minimizes moisture loss and prevents overcooking during searing, resulting in a crisp, flavorful crust. Combining sous vide with rapid nitrogen chilling offers superior control over texture and appearance compared to traditional hot searing alone.

Table of Comparison

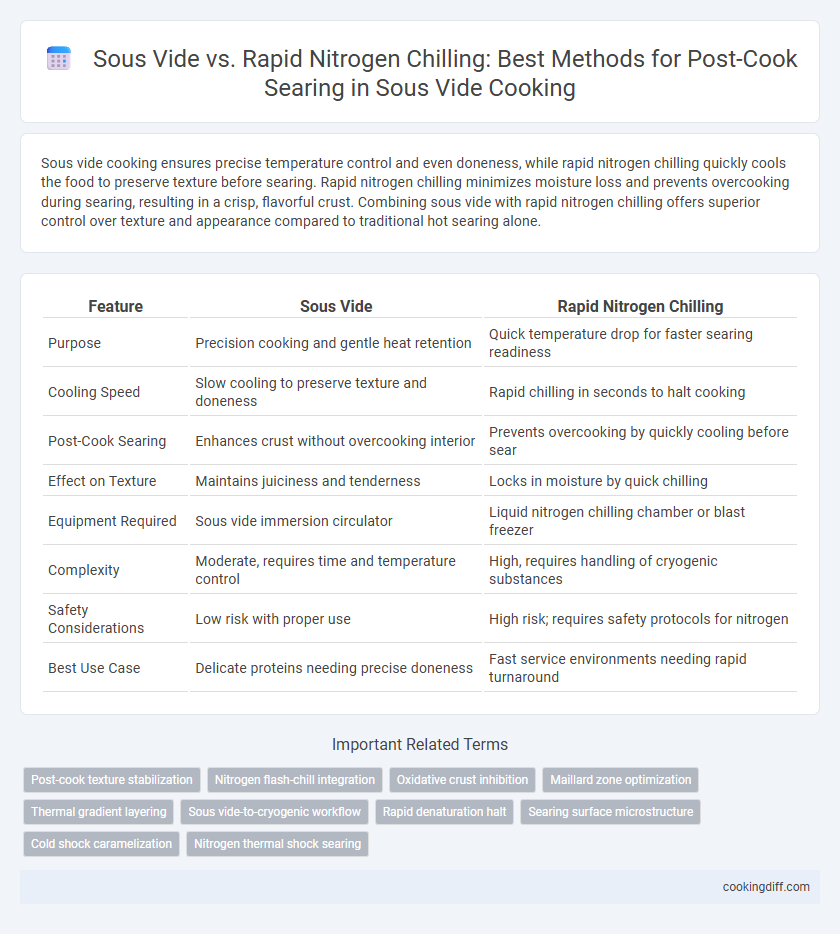

| Feature | Sous Vide | Rapid Nitrogen Chilling |

|---|---|---|

| Purpose | Precision cooking and gentle heat retention | Quick temperature drop for faster searing readiness |

| Cooling Speed | Slow cooling to preserve texture and doneness | Rapid chilling in seconds to halt cooking |

| Post-Cook Searing | Enhances crust without overcooking interior | Prevents overcooking by quickly cooling before sear |

| Effect on Texture | Maintains juiciness and tenderness | Locks in moisture by quick chilling |

| Equipment Required | Sous vide immersion circulator | Liquid nitrogen chilling chamber or blast freezer |

| Complexity | Moderate, requires time and temperature control | High, requires handling of cryogenic substances |

| Safety Considerations | Low risk with proper use | High risk; requires safety protocols for nitrogen |

| Best Use Case | Delicate proteins needing precise doneness | Fast service environments needing rapid turnaround |

Introduction to Sous Vide and Rapid Nitrogen Chilling

Sous vide is a precision cooking technique that involves vacuum-sealing food and cooking it in a water bath at a controlled temperature to ensure even doneness and enhanced flavor retention. Rapid nitrogen chilling uses liquid nitrogen to quickly cool cooked food, locking in moisture and texture before searing. Both methods optimize post-cook searing by preserving the desired internal temperature and surface quality for perfect browning.

Understanding the Science Behind Both Methods

Sous vide maintains precise temperature control during cooking, preserving moisture and tenderness by slowly bringing food to the desired doneness without overcooking. Rapid nitrogen chilling quickly cools the cooked food, allowing for immediate searing that minimizes juice loss and preserves texture.

- Sous vide temperature stability - Uses a water bath to hold food at a constant, precise temperature, ensuring even cooking throughout.

- Nitrogen chilling speed - Drops food temperature almost instantaneously, halting the cooking process and preventing carryover heat effects.

- Searing impact - Both methods prepare the food so that searing enhances crust development while maintaining internal juiciness.

Searing Goals: Flavor, Texture, and Appearance

Sous vide cooking ensures precise temperature control for optimal texture and flavor, while rapid nitrogen chilling quickly cools food to preserve these qualities before searing. Both methods aim to achieve a perfect Maillard reaction, enhancing the savory taste and appealing crust that defines high-quality searing.

Rapid nitrogen chilling minimizes moisture loss and structural damage, maintaining a firm texture ideal for quick searing, whereas sous vide-cooked foods often require careful drying to ensure even browning. Appearance is improved with rapid chilling as it prevents overcooking, preserving the vibrant color and enticing finish desired in gourmet dishes.

Sous Vide: Traditional Post-Cook Searing Techniques

Sous vide cooking preserves moisture and tenderness in meats by cooking them at precise temperatures, followed by traditional post-cook searing methods such as pan-searing or grilling. This searing step develops a flavorful crust through the Maillard reaction, enhancing texture and taste without compromising the internal doneness achieved by sous vide.

Traditional post-cook searing after sous vide involves high-heat techniques that quickly brown the surface, preserving the cook's control over the final internal temperature. Unlike rapid nitrogen chilling, which rapidly cools the food to prevent carryover cooking, traditional searing maintains warmth and creates a desirable contrast between the tender interior and the crisp exterior. This balance results in a superior dining experience highly valued in culinary applications.

Rapid Nitrogen Chilling: Innovative Approach to Searing

How does rapid nitrogen chilling improve the post-cook searing process compared to traditional sous vide methods? Rapid nitrogen chilling rapidly cools food to preserve texture and moisture before searing, minimizing overcooking risks and enhancing flavor. This innovative technique offers precise temperature control and a superior crust formation that sous vide alone may not achieve.

Temperature Control and Uniformity

Sous vide ensures precise temperature control and uniform cooking by immersing food in a water bath maintained at a consistent temperature, resulting in even doneness throughout. Rapid nitrogen chilling can cause surface temperature fluctuations, potentially leading to uneven textures during post-cook searing.

- Sous vide's controlled environment - maintains target temperatures within 0.1degC for consistent thermal penetration.

- Rapid nitrogen chilling - rapidly lowers surface temperature but can create thermal gradients affecting sear uniformity.

- Temperature uniformity - is critical in sous vide to avoid overcooking while ensuring thorough heat distribution.

Choosing sous vide over rapid nitrogen chilling optimizes temperature consistency, enhancing uniform searing results.

Impact on Meat Juiciness and Tenderness

Sous vide cooking ensures precise temperature control, resulting in evenly cooked meat with enhanced juiciness and tenderness by preventing overcooking. Rapid nitrogen chilling quickly cools the meat, which helps retain moisture but can cause minor textural changes due to thermal shock. Compared to nitrogen chilling, sous vide maintains superior meat quality by optimizing protein denaturation and moisture retention during post-cook searing.

Time Efficiency and Workflow Differences

| Method | Time Efficiency | Workflow Differences |

|---|---|---|

| Sous Vide | Requires a longer cooking and cooling time, often several hours to ensure even temperature and doneness. | Involves precise temperature control, vacuum sealing, and gradual cooling before searing, integrating smoothly into slower, planned workflows. |

| Rapid Nitrogen Chilling | Significantly reduces cooling time by flash chilling the cooked food within minutes, accelerating the searing process. | Demands specialized equipment for nitrogen chilling, allowing a faster transition from cook to sear, optimizing high-volume kitchen workflows. |

Equipment Requirements and Costs

Sous vide requires precision immersion circulators and vacuum sealers which are relatively affordable for home use, whereas rapid nitrogen chilling demands specialized cryogenic equipment with significantly higher costs. The maintenance and safety protocols for nitrogen chilling add to its overall expense and complexity compared to the more accessible sous vide systems.

- Sous vide equipment - Includes immersion circulators and vacuum sealers with moderate initial investment and low operational costs.

- Rapid nitrogen chilling equipment - Requires cryogenic tanks and safety apparatus, making it a costly and specialized solution.

- Cost comparison - Sous vide offers an economical setup for precision cooking, while nitrogen chilling involves higher expenses and technical demands.

Related Important Terms

Post-cook texture stabilization

Sous vide cooking ensures precise temperature control that evenly stabilizes the protein structure, while rapid nitrogen chilling rapidly cools the meat to halt residual cooking, preserving texture without over-tenderizing. Combining sous vide with nitrogen chilling before searing minimizes moisture loss and surface toughening, resulting in a consistent, tender post-cook texture.

Nitrogen flash-chill integration

Integrating nitrogen flash-chill with sous vide post-cook searing rapidly reduces surface temperature, preserving moisture and texture while enabling a perfectly crisp crust. This method minimizes carryover cooking compared to traditional searing, enhancing flavor and presentation through precise temperature control and rapid chilling.

Oxidative crust inhibition

Sous vide cooking combined with rapid nitrogen chilling significantly inhibits oxidative crust formation by rapidly lowering surface temperature, preserving meat's color and flavor compared to traditional searing methods. The nitrogen chilling process minimizes oxidation and Maillard reaction overdevelopment, resulting in a more controlled and visually appealing crust post-sous vide.

Maillard zone optimization

Sous vide cooking followed by rapid nitrogen chilling preserves the Maillard zone by quickly cooling the surface, minimizing moisture loss and preventing overcooking prior to searing. This method enhances crust development and flavor intensity by maintaining optimal temperature gradients essential for Maillard reactions during the final sear.

Thermal gradient layering

Sous vide cooking creates a precise thermal gradient layering that ensures even heat penetration, while rapid nitrogen chilling rapidly cools the surface to preserve texture but may disrupt the thermal gradient. This difference impacts post-cook searing, as sous vide's stable thermal layers allow for uniform Maillard reaction development, whereas nitrogen chilling can lead to uneven searing due to abrupt temperature changes.

Sous vide-to-cryogenic workflow

Sous vide-to-cryogenic workflow enhances post-cook searing by maintaining optimal internal doneness while rapidly chilling the food using liquid nitrogen to lock in moisture and texture. This method outperforms traditional sous vide with rapid nitrogen chilling by preventing overcooking during searing and preserving juiciness through precise temperature control.

Rapid denaturation halt

Rapid nitrogen chilling dramatically accelerates the halt of protein denaturation post-sous vide cooking, preserving optimal texture and juiciness by instantly lowering the internal temperature. This method prevents overcooking during searing, ensuring a precise finish with enhanced flavor retention compared to traditional rapid cooling techniques.

Searing surface microstructure

Sous vide cooking preserves moisture and tenderness by evenly cooking food at precise temperatures, while rapid nitrogen chilling aggressively cools the surface, resulting in a denser microstructure that can impact searing quality. The rapid chilling process forms a tighter protein matrix on the surface, which may reduce Maillard reaction efficiency compared to the more relaxed microstructure achieved after sous vide, affecting crust development and flavor during searing.

Cold shock caramelization

Cold shock caramelization in sous vide cooking enhances Maillard reactions by rapidly lowering the food's temperature before searing, preserving moisture and texture better than rapid nitrogen chilling. Rapid nitrogen chilling often causes uneven surface temperature drops, leading to inconsistent caramelization and a less desirable crust compared to the controlled cold shock method.

Sous vide vs rapid nitrogen chilling for post-cook searing. Infographic

cookingdiff.com

cookingdiff.com