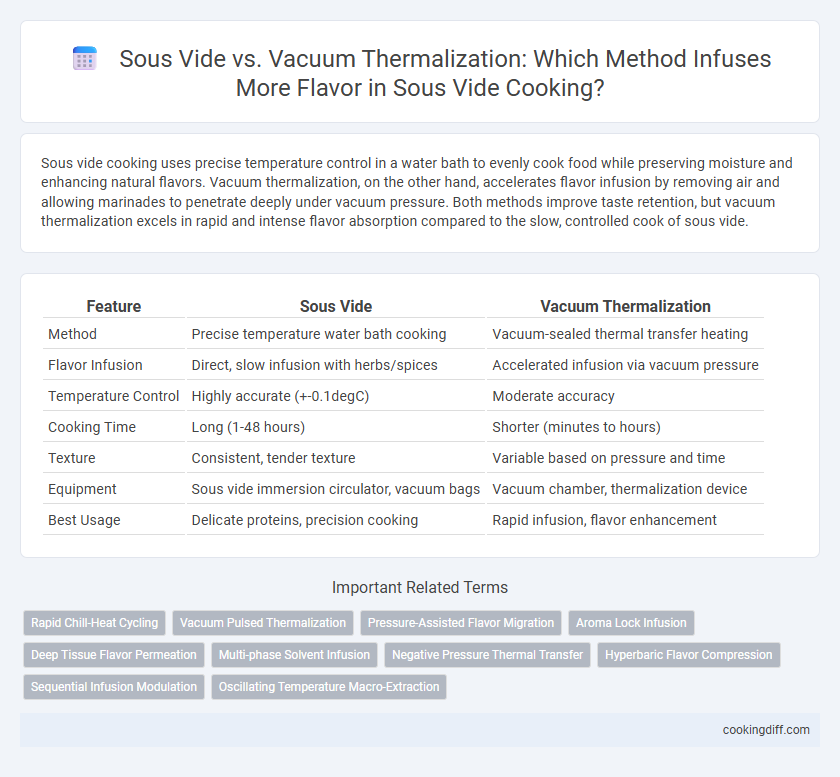

Sous vide cooking uses precise temperature control in a water bath to evenly cook food while preserving moisture and enhancing natural flavors. Vacuum thermalization, on the other hand, accelerates flavor infusion by removing air and allowing marinades to penetrate deeply under vacuum pressure. Both methods improve taste retention, but vacuum thermalization excels in rapid and intense flavor absorption compared to the slow, controlled cook of sous vide.

Table of Comparison

| Feature | Sous Vide | Vacuum Thermalization |

|---|---|---|

| Method | Precise temperature water bath cooking | Vacuum-sealed thermal transfer heating |

| Flavor Infusion | Direct, slow infusion with herbs/spices | Accelerated infusion via vacuum pressure |

| Temperature Control | Highly accurate (+-0.1degC) | Moderate accuracy |

| Cooking Time | Long (1-48 hours) | Shorter (minutes to hours) |

| Texture | Consistent, tender texture | Variable based on pressure and time |

| Equipment | Sous vide immersion circulator, vacuum bags | Vacuum chamber, thermalization device |

| Best Usage | Delicate proteins, precision cooking | Rapid infusion, flavor enhancement |

Introduction to Flavor Infusion Techniques

Sous vide cooking uses precise temperature control in vacuum-sealed bags to enhance flavor infusion and texture. Vacuum thermalization relies on vacuum pressure to accelerate the penetration of marinades and seasonings into food.

- Sous vide - Maintains consistent low temperatures to evenly infuse flavors over long cooking times.

- Vacuum thermalization - Uses rapid vacuum cycles to remove air and forcibly introduce marinade into food fibers.

- Flavor infusion - Both techniques optimize taste by controlling environment variables such as pressure, temperature, and time.

Understanding Sous Vide Cooking

Sous vide cooking involves sealing food in a vacuum bag and cooking it in a precisely controlled water bath, ensuring even temperature and enhanced flavor retention. This method contrasts with traditional vacuum thermalization, which primarily focuses on rapid chilling or warming without consistent heat application for flavor development.

Sous vide optimizes flavor infusion by allowing prolonged exposure to low temperatures, facilitating the breakdown of proteins and the melding of spices directly into the food. Vacuum thermalization lacks this controlled cooking phase, limiting its capacity to enhance taste compared to sous vide techniques.

What Is Vacuum Thermalization?

| Vacuum Thermalization | Vacuum thermalization is a cooking technique where food sealed in vacuum bags is gently heated in a controlled water bath, allowing even and precise temperature distribution throughout the product. This method enhances flavor infusion by enabling marinades and spices to penetrate more deeply compared to traditional cooking methods. Unlike sous vide, which relies on longer cooking times at lower temperatures, vacuum thermalization can achieve flavor and texture improvements in shorter time frames while maintaining food safety. |

Flavor Infusion Mechanisms: Sous Vide vs Vacuum Thermalization

Sous vide uses a precise temperature-controlled water bath to enhance flavor infusion by evenly cooking food within vacuum-sealed bags, preserving aromas and juices. Vacuum thermalization employs pressure changes to accelerate marinade penetration but may not achieve the same depth of flavor as slow sous vide cooking.

- Sous Vide Temperature Control - Maintains consistent low heat to break down proteins gently, allowing flavors to infuse gradually and uniformly.

- Vacuum Pressure Variation - Uses alternating vacuum and atmospheric pressure to force marinades into food more quickly but often results in surface-level flavoring.

- Flavor Retention - Sous vide's sealed environment prevents flavor loss, while vacuum thermalization's rapid process can cause some aromatic evaporation.

Precision and Control: Temperature and Time

Sous vide offers unparalleled precision and control over temperature and time, ensuring consistent flavor infusion by cooking food at exact, stable temperatures. Vacuum thermalization, while also using vacuum sealing, lacks the same fine temperature regulation, resulting in less consistent flavor penetration and texture. The accuracy of sous vide reduces the risk of overcooking and maximizes the depth of flavor absorption during the cooking process.

Ingredient Compatibility for Each Method

Sous vide cooking ensures consistent temperature control, enhancing the natural flavors of delicate ingredients like fish and vegetables without overcooking. Vacuum thermalization excels at infusing intense flavors into denser proteins such as beef and pork by using pressure to deepen marinade penetration.

- Sous Vide Compatible - Ideal for tender cuts and temperature-sensitive foods that benefit from gentle, even cooking.

- Vacuum Thermalization Compatible - Best suited for dense, tougher meats requiring enhanced flavor absorption through vacuum pressure.

- Ingredient Texture Impact - Sous vide maintains ingredient integrity while vacuum thermalization can alter texture via pressure effects.

Choosing the right method depends on the ingredient's texture and desired flavor intensity for optimal culinary results.

Comparing Flavor Intensities

How do flavor intensities compare between sous vide and vacuum thermalization methods? Sous vide cooking gently immerses ingredients in a precisely controlled water bath, preserving and evenly distributing natural flavors and enhancing tenderization. Vacuum thermalization, while also using sealed environments, often applies heat more rapidly, which can result in less uniform flavor infusion compared to the consistent temperature control of sous vide.

Equipment Requirements and Accessibility

Sous vide requires precise immersion circulators and vacuum sealers, making it more equipment-intensive compared to basic vacuum thermalization, which often uses simpler vacuum chambers without temperature control. The accessibility of sous vide devices has improved with affordable home units, whereas vacuum thermalization remains niche and primarily industrial.

Vacuum thermalization relies on vacuum pressure alone to infuse flavors, minimizing equipment costs but lacking the precise temperature regulation of sous vide machines necessary for consistent results. Sous vide offers enhanced control over cooking environments, yielding more predictable flavor infusion through exact temperature maintenance. While sous vide demands a higher initial investment, its growing market availability has increased accessibility for home cooks seeking professional-quality flavor enhancement.

Practical Applications and Recipe Examples

Sous vide ensures precise temperature control, allowing flavors to infuse evenly by sealing ingredients in vacuum bags and cooking them at consistent low heat. Recipes like herb-infused chicken breasts or garlic butter shrimp benefit from this method, achieving tender textures and intensified taste profiles.

Vacuum thermalization accelerates flavor infusion by rapidly cooling or heating vacuum-sealed food, useful in marinating processes or quick pickling. Practical applications include vacuum-thermally-treated steak marinades or vegetable brining, enhancing flavor penetration without overcooking.

Related Important Terms

Rapid Chill-Heat Cycling

Rapid Chill-Heat Cycling in sous vide enhances flavor infusion by repeatedly exposing food to precise temperature shifts, accelerating the absorption of marinades compared to traditional vacuum thermalization. This method optimizes molecular interaction between the food and seasoning, resulting in more intense and uniform flavor profiles.

Vacuum Pulsed Thermalization

Vacuum Pulsed Thermalization enhances flavor infusion by rapidly and evenly distributing marinades through controlled pressure cycles, outperforming traditional sous vide methods that rely solely on temperature precision. This technique accelerates protein absorption and intensifies seasoning depth, resulting in richer taste profiles with improved texture consistency.

Pressure-Assisted Flavor Migration

Pressure-assisted flavor migration during sous vide cooking enhances infusion by accelerating the penetration of marinades and seasonings into food, surpassing traditional vacuum thermalization methods. This technique applies controlled pressure to force flavor compounds deeper and more uniformly, resulting in intensified taste and improved texture without overcooking.

Aroma Lock Infusion

Aroma Lock Infusion in sous vide cooking enhances flavor penetration by gently sealing volatile aroma compounds within vacuum-sealed bags, ensuring maximum retention and intensified taste profiles. Unlike standard vacuum thermalization, this technique specifically targets aroma preservation, creating a richer, more aromatic culinary experience.

Deep Tissue Flavor Permeation

Sous vide cooking ensures deep tissue flavor permeation by maintaining precise temperature control, allowing marinades and seasonings to slowly infuse into the food's inner fibers. Vacuum thermalization, while effective for rapid temperature equalization, offers less opportunity for prolonged flavor integration compared to the extended sous vide process.

Multi-phase Solvent Infusion

Sous vide combined with multi-phase solvent infusion enhances flavor penetration by using precise temperature control to optimize vacuum thermalization, allowing solvents to dissolve and transport flavor compounds uniformly into the food matrix. This method ensures deeper infusion and consistent taste profiles compared to traditional vacuum-sealed thermalization alone, maximizing aromatic and savory compound absorption.

Negative Pressure Thermal Transfer

Negative Pressure Thermal Transfer in sous vide offers superior flavor infusion compared to traditional vacuum thermalization by enhancing heat and flavor molecule penetration through reduced pressure environments. This method accelerates marination processes and intensifies taste profiles by enabling more efficient diffusion of spices and seasonings into the food matrix.

Hyperbaric Flavor Compression

Hyperbaric flavor compression leverages increased pressure during sous vide cooking to accelerate the infusion of marinades and spices, enhancing depth and uniformity of taste compared to standard vacuum thermalization. This method intensifies aromatic compound absorption by reducing cooking time and preserving volatile flavors, resulting in richer and more complex culinary profiles.

Sequential Infusion Modulation

Sous vide employs precise temperature control for uniform cooking and flavor infusion, while vacuum thermalization enhances Sequential Infusion Modulation by promoting deeper penetration of marinades and seasonings through controlled vacuum pressure cycles. This method optimizes molecular interactions, resulting in intensified flavors and improved texture consistency in the cooked food.

Sous vide vs vacuum thermalization for flavor infusion. Infographic

cookingdiff.com

cookingdiff.com