Vacuum sealers create airtight bags that preserve pet food freshness by removing air, but basic models work best with dry foods due to their external suction mechanism. Chamber vacuum sealers offer stronger, more consistent seals by evacuating air inside an airtight chamber, making them ideal for wet or moist pet foods. This method prevents liquid from being sucked out, ensuring perfectly sealed bags for sous vide pet food preparation.

Table of Comparison

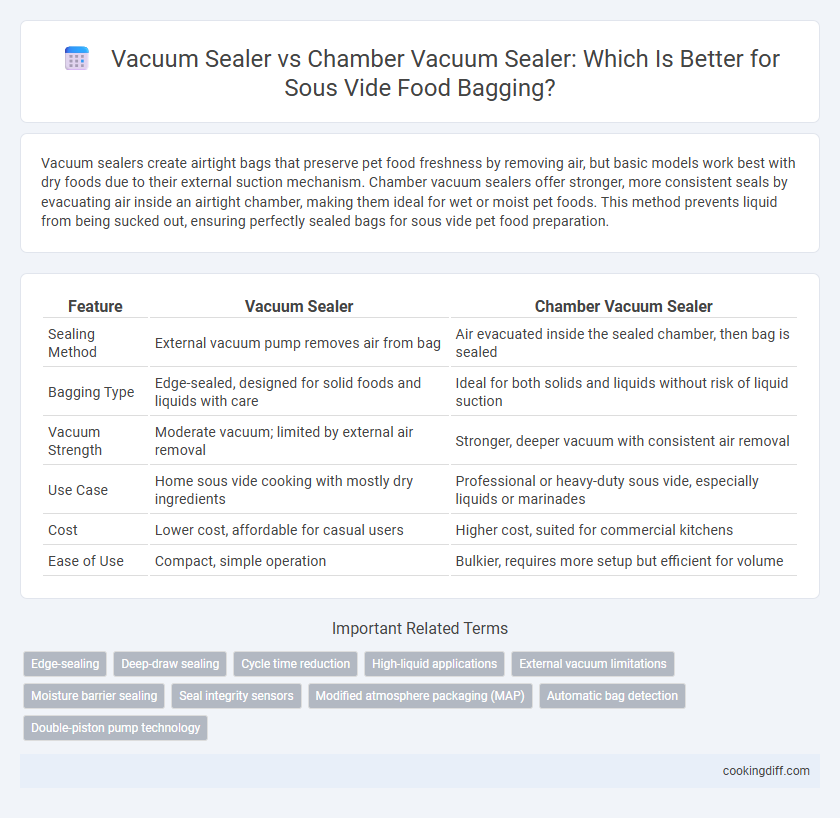

| Feature | Vacuum Sealer | Chamber Vacuum Sealer |

|---|---|---|

| Sealing Method | External vacuum pump removes air from bag | Air evacuated inside the sealed chamber, then bag is sealed |

| Bagging Type | Edge-sealed, designed for solid foods and liquids with care | Ideal for both solids and liquids without risk of liquid suction |

| Vacuum Strength | Moderate vacuum; limited by external air removal | Stronger, deeper vacuum with consistent air removal |

| Use Case | Home sous vide cooking with mostly dry ingredients | Professional or heavy-duty sous vide, especially liquids or marinades |

| Cost | Lower cost, affordable for casual users | Higher cost, suited for commercial kitchens |

| Ease of Use | Compact, simple operation | Bulkier, requires more setup but efficient for volume |

Introduction to Vacuum Sealer Options for Sous Vide

Vacuum sealers are essential for sous vide cooking, providing airtight bags that preserve flavor and texture. Standard vacuum sealers suit home cooks sealing flat bags, while chamber vacuum sealers efficiently handle liquids and marinated foods by sealing in a controlled vacuum chamber. Choosing the right sealer depends on bagging volume and the types of ingredients used in sous vide recipes.

How External Vacuum Sealers Work

External vacuum sealers remove air by pulling it out through the open edge of a specially designed bag before sealing it tightly with heat. This process helps preserve food freshness and prevents freezer burn by limiting air exposure.

- Air Extraction - The sealer creates a vacuum by suctioning air from the bag's open end using a small pump mechanism.

- Heat Sealing - Once air is removed, a heating element melts the bag's edges together to form an airtight seal.

- Manual Bag Placement - Food must be placed in compatible vacuum bags manually before the sealer begins the vacuum and sealing cycle.

Chamber Vacuum Sealers: Technology Explained

What distinguishes chamber vacuum sealers from traditional vacuum sealers in food bagging? Chamber vacuum sealers use a sealed environment to remove air from the entire bag, creating a complete vacuum that preserves food freshness more effectively. This technology allows for sealing liquids without leakage, making it ideal for sous vide cooking and long-term storage.

Key Differences Between Vacuum and Chamber Sealers

| Key Differences | Vacuum Sealer | Chamber Vacuum Sealer |

|---|---|---|

| Sealing Method | Removes air from the bag by suction outside the device. | Removes air by creating a vacuum inside a sealed chamber, extracting air from the entire bag. |

| Suitability | Ideal for dry or semi-dry foods due to limited moisture handling capabilities. | Excellent for liquid-rich or marinated foods as it prevents liquid from being sucked out during sealing. |

| Pressure and Air Removal | Relies on external vacuum pressure, less efficient with porous or irregularly shaped items. | Achieves higher vacuum pressure uniformly, allowing better air removal and longer storage life. |

Bag Compatibility: What Fits Best in Each Sealer

Vacuum sealers and chamber vacuum sealers differ significantly in bag compatibility, impacting sous vide cooking efficiency. Choosing the right sealer depends on the size and type of bags best suited for the food you plan to seal.

- External Vacuum Sealers - Typically use bags with open ends that fit standard rolls or pre-cut sizes, ideal for smaller portions or irregularly shaped items.

- Chamber Vacuum Sealers - Accommodate thicker, multi-layer bags that withstand higher vacuum pressure, perfect for larger or liquid-rich foods.

- Bag Material Compatibility - Chamber sealers support a wider variety of bag materials, including embossed and smooth surfaces, enhancing airtight seals for sous vide.

Selecting the appropriate sealer based on bag compatibility ensures optimal vacuum integrity and sous vide cooking results.

Seal Strength and Liquid Handling Comparisons

Chamber vacuum sealers provide superior seal strength by evenly distributing pressure around the entire bag, ensuring a more secure and airtight seal compared to external vacuum sealers. They excel in handling liquids and moist foods, preventing spills and maintaining vacuum integrity during the sealing process. External vacuum sealers often struggle with liquids, increasing the risk of seal failure and compromising food preservation in sous vide cooking.

Cost Analysis: Upfront and Long-term Considerations

Vacuum sealers typically have a lower upfront cost, ranging from $30 to $100, making them ideal for casual sous vide enthusiasts. Chamber vacuum sealers, though priced between $400 and $1,000, offer superior sealing for liquids and extended durability, benefiting frequent or professional use.

Over time, chamber vacuum sealers reduce the need for replacement bags due to better air removal and stronger seals, which can lower long-term costs. Regular vacuum sealers may require more frequent bag purchases and maintenance, impacting overall affordability during sustained sous vide cooking.

Ease of Use and Maintenance Factors

Vacuum sealers offer straightforward operation with minimal upkeep, ideal for casual sous vide enthusiasts. Chamber vacuum sealers require more maintenance but provide superior sealing quality and adaptability for wet or liquid-rich foods.

- Ease of Use - Standard vacuum sealers typically feature one-button operation suitable for home cooks.

- Maintenance - Chamber vacuum sealers demand regular cleaning and filter replacement to maintain performance.

- Performance - Chamber models handle liquids better, reducing the risk of bag punctures during sealing.

Performance with Marinades and Liquids for Sous Vide

Chamber vacuum sealers provide superior performance with marinades and liquids by evenly removing air without sucking out the liquid, ensuring a tight seal that enhances flavor infusion during sous vide cooking.

Standard vacuum sealers struggle with liquids, often causing the marinade to be sucked into the machine, which can disrupt sealing and reduce the effectiveness of marinating in sous vide.

Related Important Terms

Edge-sealing

Vacuum sealers create airtight bags by removing air and sealing one edge, while chamber vacuum sealers use a pressurized chamber to evenly evacuate air and seal all edges, resulting in stronger, more durable edge-sealing ideal for sous vide cooking. The superior edge-sealing technology of chamber vacuum sealers prevents leaks and maintains vacuum integrity during extended cooking times, enhancing food preservation and texture.

Deep-draw sealing

Deep-draw sealing in vacuum sealers creates a strong, airtight bag by tightly molding the plastic around food, preserving freshness and preventing freezer burn during sous vide cooking. Chamber vacuum sealers excel at deep-draw sealing by evacuating air more efficiently and handling liquid-rich foods without bag collapse, making them ideal for precise sous vide preparation compared to external vacuum sealers.

Cycle time reduction

Vacuum sealers and chamber vacuum sealers differ significantly in cycle time efficiency, with chamber vacuum sealers reducing cycle times by evacuating air from the entire chamber, allowing for faster and more consistent sealing, especially with liquids or moist foods. This technology minimizes the need for multiple sealing passes, optimizing sous vide preparation by accelerating bagging processes and improving overall workflow.

High-liquid applications

Chamber vacuum sealers excel in high-liquid applications by creating a vacuum inside the entire chamber, preventing liquids from being sucked out during sealing, unlike external vacuum sealers which can struggle with liquid displacement and incomplete seals. These machines are ideal for sous vide cooking where maintaining liquid integrity within bags ensures precise temperature control and flavor retention.

External vacuum limitations

External vacuum sealers often struggle with sealing liquids and wet foods due to limited suction power and air removal capabilities, leading to imperfect seals and potential bag leaks. Chamber vacuum sealers create a vacuum inside the entire chamber, allowing them to efficiently handle liquids and moist foods without compromising seal integrity, making them more suitable for sous vide preparation.

Moisture barrier sealing

Vacuum sealers create a strong moisture barrier by removing air and sealing the bag, preserving food texture and flavor during sous vide cooking. Chamber vacuum sealers excel in moisture barrier sealing for wet or liquid-rich foods by evacuating air within the entire chamber, preventing liquid suction and ensuring a tight, leak-proof seal.

Seal integrity sensors

Vacuum sealers with advanced seal integrity sensors monitor pressure and temperature to ensure airtight seals, preventing air leaks that can compromise sous vide cooking precision. Chamber vacuum sealers offer enhanced sensor calibration and uniform sealing pressure, making them ideal for consistently maintaining optimal vacuum levels in sous vide bagging.

Modified atmosphere packaging (MAP)

Vacuum sealers remove air from bags to extend shelf life, but chamber vacuum sealers enhance Modified Atmosphere Packaging (MAP) by removing air and allowing gas flushing to replace oxygen with nitrogen or carbon dioxide, optimizing food freshness and safety. Chamber vacuum sealers create a controlled environment crucial for precise MAP applications, making them ideal for sous vide cooking and long-term storage.

Automatic bag detection

Chamber vacuum sealers offer superior automatic bag detection by sealing entire bags within a controlled environment, ensuring consistent vacuum pressure and preventing air leaks during the sous vide process. In contrast, standard vacuum sealers may struggle with automatic bag detection, often requiring manual adjustments that can compromise seal integrity and food preservation.

Vacuum sealer vs chamber vacuum sealer for bagging food. Infographic

cookingdiff.com

cookingdiff.com