A metal perforated tray offers superior durability and heat conduction, ensuring even steam distribution for perfectly cooked food. In contrast, a nonstick micro-perforated tray provides easy food release and simple cleanup, while its smaller perforations prevent smaller ingredients from slipping through. Choosing between the two depends on whether durability or convenience is the priority in your steaming process.

Table of Comparison

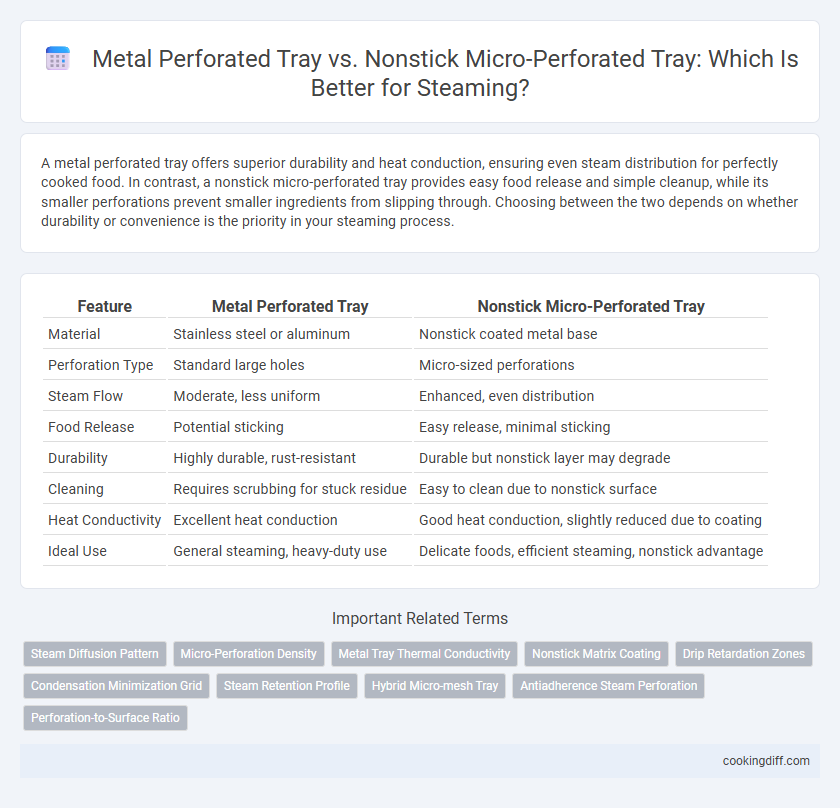

| Feature | Metal Perforated Tray | Nonstick Micro-Perforated Tray |

|---|---|---|

| Material | Stainless steel or aluminum | Nonstick coated metal base |

| Perforation Type | Standard large holes | Micro-sized perforations |

| Steam Flow | Moderate, less uniform | Enhanced, even distribution |

| Food Release | Potential sticking | Easy release, minimal sticking |

| Durability | Highly durable, rust-resistant | Durable but nonstick layer may degrade |

| Cleaning | Requires scrubbing for stuck residue | Easy to clean due to nonstick surface |

| Heat Conductivity | Excellent heat conduction | Good heat conduction, slightly reduced due to coating |

| Ideal Use | General steaming, heavy-duty use | Delicate foods, efficient steaming, nonstick advantage |

Introduction to Steaming: The Importance of the Right Tray

Choosing the right tray for steaming significantly affects cooking efficiency and food quality. Metal perforated trays offer durability and excellent heat conduction, while nonstick micro-perforated trays provide easy food release and minimal sticking.

- Metal perforated trays - Enhance steam circulation with larger holes, promoting even cooking and faster heat distribution.

- Nonstick micro-perforated trays - Feature smaller perforations that reduce food sticking and support gentle steaming of delicate items.

- Tray material impact - Influences cleaning ease, durability, and overall steaming performance in kitchen appliances.

Metal Perforated Tray: Features and Benefits

Metal perforated trays offer superior heat conduction, ensuring even steam circulation and faster cooking times compared to nonstick micro-perforated trays. Their durable stainless steel construction resists warping and high temperatures, enhancing longevity and maintaining structural integrity. The larger perforations allow better moisture drainage, preventing sogginess and promoting optimal steaming results for vegetables and seafood.

Nonstick Micro-Perforated Tray: Features and Advantages

| Material | Nonstick coated alloy for easy food release and durability |

| Perforation Design | Micro-perforations enhance steam circulation for even cooking |

| Cleaning Ease | Nonstick surface reduces food residue buildup, simplifying cleanup |

| Corrosion Resistance | High resistance to rust and staining compared to metal perforated trays |

| Cooking Efficiency | Micro-perforations minimize drip loss while maximizing steam penetration |

Heat Distribution: Metal vs. Nonstick Micro-Perforated Trays

Metal perforated trays provide superior heat distribution due to their excellent thermal conductivity, allowing steam to circulate evenly and cook food faster. This results in consistent steaming performance and better texture retention in vegetables and seafood.

Nonstick micro-perforated trays offer targeted steam flow through smaller holes, enhancing moisture retention but often sacrificing uniform heat transfer compared to metal trays. These trays are ideal for delicate foods that benefit from gentle steaming, while metal trays excel in robust heat distribution for a wider variety of dishes.

Steam Circulation Efficiency Compared

Metal perforated trays offer superior steam circulation efficiency due to their durable structure and larger perforations, allowing steam to pass freely and cook food evenly. Nonstick micro-perforated trays have smaller holes, which can restrict steam flow and reduce overall steaming performance.

Steam circulation is critical for consistent cooking, and metal trays maximize this by preventing condensation buildup. The enhanced airflow in metal perforated trays reduces cooking time and improves texture by ensuring uniform heat distribution. Nonstick micro-perforated trays may be easier to clean but sacrifice efficiency compared to metal options.

Food Release and Cleaning: Nonstick vs. Traditional Metal

Nonstick micro-perforated trays offer superior food release compared to traditional metal perforated trays, reducing the risk of food sticking during steaming. The nonstick coating enables effortless cleaning, as residue and moisture do not cling to the surface, unlike conventional metal which often requires more vigorous scrubbing. Metal perforated trays may develop rust or discoloration over time, whereas nonstick trays maintain their smooth surface for prolonged usability and hygiene.

Durability and Longevity: Which Tray Lasts Longer?

Which tray offers better durability and longevity for steaming: metal perforated or nonstick micro-perforated? Metal perforated trays are typically made from stainless steel or aluminum, providing superior resistance to warping, scratching, and corrosion over time. Nonstick micro-perforated trays may wear out faster due to coating degradation from repeated heating and cleaning cycles.

Cooking Results: Texture and Flavor Differences

Metal perforated trays provide excellent heat conduction, resulting in evenly cooked food with a firm texture and enhanced caramelization that intensifies flavor. Their sturdy structure allows steam to circulate freely, producing distinctively crisp edges and a more concentrated taste.

Nonstick micro-perforated trays prevent food from sticking, preserving delicate textures and making cleanup easier. The micro-perforations offer gentler steam flow which helps retain moisture, yielding softer textures and a milder, more subtle flavor profile.

Health and Safety Considerations

Metal perforated trays offer durability and are less likely to leach harmful substances into food during steaming. Nonstick micro-perforated trays provide easy cleanup but may release toxic fumes if overheated, raising health concerns.

- Durability - Metal trays resist wear and corrosion, ensuring long-term safe use.

- Chemical Safety - Nonstick coatings can degrade at high temps, potentially emitting hazardous chemicals.

- Food Contact - Metal trays are inert, minimizing risks of food contamination.

Choosing a metal perforated tray enhances health and safety during steaming by avoiding chemical exposure risks.

Related Important Terms

Steam Diffusion Pattern

Metal perforated trays provide an even steam diffusion pattern due to their rigid structure and uniform hole distribution, ensuring consistent heat transfer and optimal cooking results. Nonstick micro-perforated trays offer finer steam dispersion, promoting gentle cooking and reducing food sticking, but may result in slightly less uniform steam flow compared to traditional metal trays.

Micro-Perforation Density

Metal perforated trays with higher micro-perforation density ensure more uniform steam distribution, reducing cooking time and enhancing food texture compared to standard perforated trays. Nonstick micro-perforated trays offer the added benefit of easy food release and cleaning, maintaining efficient steam flow while preventing food from sticking.

Metal Tray Thermal Conductivity

Metal perforated trays offer superior thermal conductivity compared to nonstick micro-perforated trays, enabling faster and more even heat distribution during steaming. This efficient heat transfer enhances cooking performance and helps retain food texture and nutrients.

Nonstick Matrix Coating

Nonstick micro-perforated trays with advanced matrix coating provide superior steam circulation and prevent food from sticking, ensuring even cooking and easy cleanup compared to traditional metal perforated trays. The nonstick matrix coating enhances durability and maintains consistent heat distribution, making it ideal for delicate steaming tasks.

Drip Retardation Zones

Metal perforated trays feature Drip Retardation Zones that enhance steam circulation while minimizing water accumulation, preventing soggy food during steaming. Nonstick micro-perforated trays offer finer holes but may lack the engineered drip retardation design, potentially causing uneven steaming and increased moisture retention.

Condensation Minimization Grid

Metal perforated trays offer superior heat conductivity and durability, creating more evenly distributed steam while their condensation minimization grids reduce water pooling for better food texture. Nonstick micro-perforated trays feature finer perforations that limit steam loss and improve condensation runoff but may wear down faster under high heat, potentially affecting long-term performance.

Steam Retention Profile

Metal perforated trays offer superior steam retention due to their high thermal conductivity and open-hole design, facilitating even heat distribution and consistent steam circulation during cooking. Nonstick micro-perforated trays, while easier to clean and food-release friendly, may compromise steam retention slightly because smaller perforations reduce overall steam flow and heat transfer efficiency.

Hybrid Micro-mesh Tray

The hybrid micro-mesh tray combines the durability of metal perforated trays with the easy-release benefits of nonstick micro-perforated trays, enhancing steam circulation for uniform cooking. Its advanced micro-perforation design ensures optimal moisture retention while preventing food from sticking, making it ideal for precise and efficient steaming.

Antiadherence Steam Perforation

Metal perforated trays provide durable, heat-conductive surfaces with precise antiadherence steam perforations that enhance even steam distribution and prevent food from sticking during cooking. Nonstick micro-perforated trays offer finer perforations combined with a nonstick coating, improving antiadherence properties and enabling easier food release while maintaining consistent steam flow and flavor retention.

Metal perforated tray vs nonstick micro-perforated tray for steaming. Infographic

cookingdiff.com

cookingdiff.com