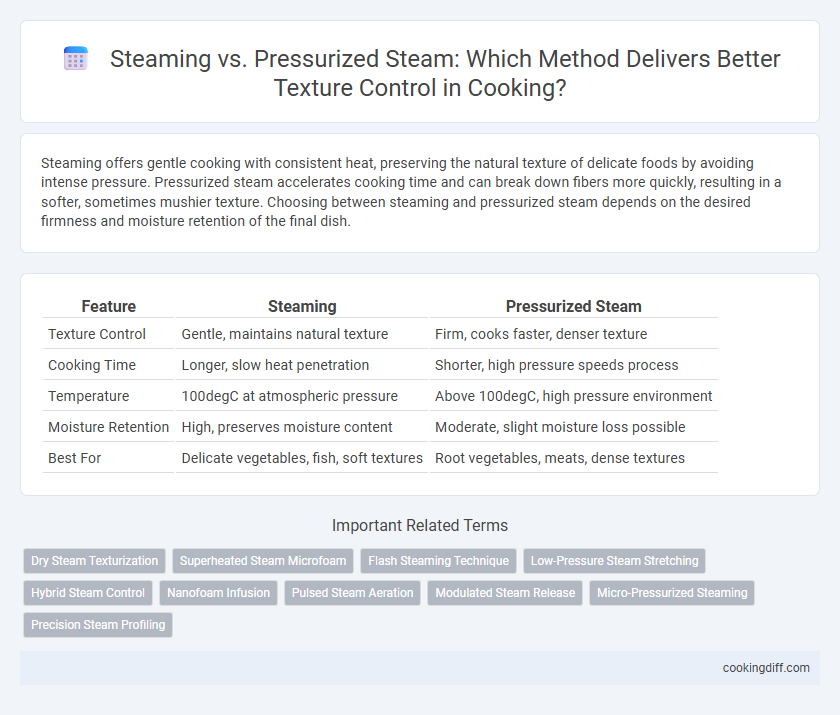

Steaming offers gentle cooking with consistent heat, preserving the natural texture of delicate foods by avoiding intense pressure. Pressurized steam accelerates cooking time and can break down fibers more quickly, resulting in a softer, sometimes mushier texture. Choosing between steaming and pressurized steam depends on the desired firmness and moisture retention of the final dish.

Table of Comparison

| Feature | Steaming | Pressurized Steam |

|---|---|---|

| Texture Control | Gentle, maintains natural texture | Firm, cooks faster, denser texture |

| Cooking Time | Longer, slow heat penetration | Shorter, high pressure speeds process |

| Temperature | 100degC at atmospheric pressure | Above 100degC, high pressure environment |

| Moisture Retention | High, preserves moisture content | Moderate, slight moisture loss possible |

| Best For | Delicate vegetables, fish, soft textures | Root vegetables, meats, dense textures |

Introduction to Steaming Methods for Texture Control

Steaming and pressurized steam are two principal methods used to control texture in food preparation, each affecting moisture retention and tenderness differently. Steaming involves cooking food with the vapor from boiling water at atmospheric pressure, resulting in gentle heat transfer that preserves delicate textures. Pressurized steam increases the temperature and pressure inside the cooking environment, accelerating cooking time and producing a firmer, more uniform texture in ingredients like vegetables and meats.

Understanding Conventional Steaming

Conventional steaming uses atmospheric pressure to cook food by surrounding it with steam at 100degC, resulting in gentle and even heat distribution. This method preserves the natural texture and moisture of ingredients, making it ideal for delicate foods like vegetables and fish.

Pressurized steam operates at higher temperatures due to increased pressure, which accelerates cooking but can alter food texture more aggressively. Understanding conventional steaming highlights its role in maintaining food integrity through controlled, low-temperature steaming without compromising texture.

What Is Pressurized Steam Cooking?

Pressurized steam cooking utilizes high-pressure steam to cook food faster and more evenly than traditional steaming. This method enhances texture control by allowing precise regulation of temperature and moisture levels during cooking.

- High Pressure - Steam is generated at pressures above atmospheric level, increasing cooking temperature and speed.

- Texture Precision - The controlled environment helps maintain desired firmness or tenderness in food textures.

- Moisture Retention - Pressurized steam minimizes water contact, preserving nutrients and preventing sogginess.

Key Differences: Conventional vs Pressurized Steam

Conventional steaming uses atmospheric pressure to cook food, resulting in gentle heat that maintains natural textures and moisture levels. Pressurized steam employs higher pressure, increasing the boiling point of water to cook food faster and often producing a firmer texture.

While conventional steam allows precise control over delicate textures, pressurized steam excels in tenderizing tougher ingredients quickly. The choice between these methods depends on desired texture outcomes and cooking time efficiency.

Impact on Food Texture: Gentle Steaming

Gentle steaming preserves the natural texture of delicate foods by using lower temperatures and non-pressurized steam. This method prevents overcooking and maintains moisture, resulting in a tender and uniform texture.

- Texture Preservation - Gentle steaming avoids excessive heat, protecting the structural integrity of vegetables and seafood.

- Moisture Retention - The low-pressure environment minimizes water loss, keeping foods juicy and soft.

- Even Cooking - Non-pressurized steam distributes heat steadily, ensuring consistent texture without toughening.

Using gentle steaming techniques offers superior control over food texture compared to pressurized steam methods.

Effects of Pressurized Steam on Texture

How does pressurized steam influence the texture of food compared to traditional steaming? Pressurized steam subjects food to higher temperatures and moisture levels, resulting in faster cooking times and more consistent texture. This method often produces a tender yet firm texture, enhancing moisture retention and preventing overcooking in delicate ingredients.

Moisture Retention and Texture Comparison

Steaming uses atmospheric pressure to gently cook food, preserving moisture and resulting in a tender texture. Pressurized steam, generated in pressure cookers, reaches higher temperatures which can reduce cooking time but may cause slight moisture loss.

Moisture retention is typically higher in traditional steaming due to the lower temperature and gentler process, enhancing the juiciness of delicate foods like vegetables and fish. Pressurized steam's intense heat can break down fibers faster, creating a softer, sometimes mushier texture. Choosing between steaming and pressurized steam ultimately depends on the desired texture and cooking speed preferences.

Optimal Foods for Each Steaming Technique

| Steaming Technique | Optimal Foods | Texture Control |

|---|---|---|

| Traditional Steaming | Delicate vegetables, fish, dumplings | Preserves natural texture and moisture, results in tender and slightly crisp foods |

| Pressurized Steam | Root vegetables, tough meats, legumes | Breaks down fibers quickly, producing softer and more uniform textures |

Culinary Tips: Choosing the Best Method for Desired Texture

Steaming uses gentle, low-pressure steam ideal for preserving the natural texture and moisture of delicate foods like vegetables and fish. Pressurized steam, found in devices like pressure cookers, cooks food faster and can create a firmer texture by breaking down fibers more aggressively. Choosing between the two depends on the desired texture outcome: opt for steaming for tender, crisp results and pressurized steam for soft, well-cooked dishes.

Related Important Terms

Dry Steam Texturization

Dry steam texturization uses low-moisture steam at high temperatures to achieve precise texture control, enhancing the firmness and mouthfeel of foods without adding excess moisture. Unlike pressurized steam, dry steam minimizes water absorption, resulting in crispier, well-defined textures ideal for products requiring structural integrity.

Superheated Steam Microfoam

Superheated steam microfoam enhances texture control by producing finer, drier bubbles compared to pressurized steam, resulting in smoother, silkier microfoam ideal for specialty coffee beverages. This method maintains consistent steam temperature and reduces moisture content, optimizing milk frothing precision and overall sensory quality.

Flash Steaming Technique

Flash steaming rapidly exposes food to high-temperature steam for seconds, enhancing texture by loosening cell walls without overcooking. This precise control contrasts with pressurized steam, which uses sustained high pressure and temperature but risks uneven texture or sogginess.

Low-Pressure Steam Stretching

Low-pressure steam stretching offers precise texture control by gently expanding fibers without causing structural damage, ideal for delicate fabrics. Compared to high-pressure steam, it reduces the risk of over-shrinking and preserves material integrity, ensuring consistent softness and flexibility.

Hybrid Steam Control

Hybrid steam control combines the benefits of both steaming and pressurized steam to optimize texture control in food preparation, offering precise regulation of moisture and temperature. This method enhances consistency and tenderness by balancing gentle steam infusion with controlled pressure adjustments, resulting in superior texture outcomes.

Nanofoam Infusion

Nanofoam infusion enhances texture control by allowing precise modulation of steam diffusion during both steaming and pressurized steam applications. Pressurized steam delivers rapid, uniform heat penetration ideal for compact nanofoam structures, while traditional steaming provides gentler, controlled moisture absorption that preserves delicate textures in infused nanofoam materials.

Pulsed Steam Aeration

Pulsed steam aeration enhances texture control by using intermittent bursts of pressurized steam to evenly distribute heat and moisture, resulting in improved food tenderness and consistent cooking outcomes. This technique offers precision beyond traditional continuous steaming, optimizing aeration and preventing over-saturation or uneven texture development.

Modulated Steam Release

Modulated steam release during steaming offers precise control over moisture and temperature, enabling superior texture customization in food preparation. Unlike pressurized steam, which delivers constant high heat, modulated steaming adjusts steam intensity to optimize tenderness and maintain structural integrity.

Micro-Pressurized Steaming

Micro-pressurized steaming enhances texture control by delivering steam at precise pressure levels, resulting in consistent moisture retention and uniform softness compared to traditional steaming methods. This technique optimizes heat penetration and minimizes overcooking, improving the texture quality of delicate foods such as vegetables and seafood.

Steaming vs Pressurized Steam for Texture Control Infographic

cookingdiff.com

cookingdiff.com