Steaming provides intense, direct moisture that helps bread develop a shiny crust and retain internal softness, ideal for artisan loaves. Steam convection combines steam with hot circulating air, promoting even heat distribution and consistent crust formation, resulting in bread with a uniform golden-brown finish. Choosing between steaming and steam convection depends on the desired crust texture and baking environment efficiency.

Table of Comparison

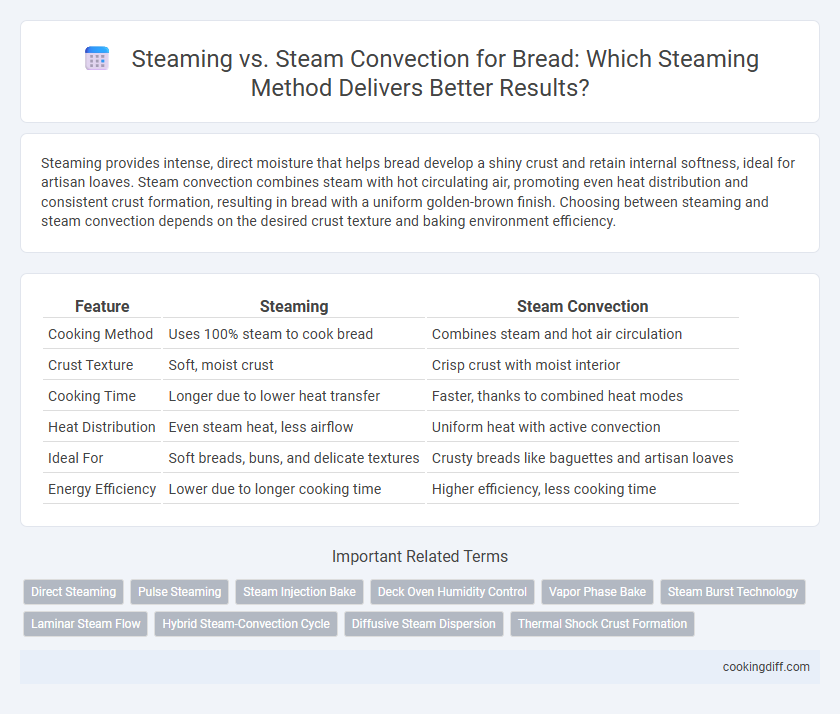

| Feature | Steaming | Steam Convection |

|---|---|---|

| Cooking Method | Uses 100% steam to cook bread | Combines steam and hot air circulation |

| Crust Texture | Soft, moist crust | Crisp crust with moist interior |

| Cooking Time | Longer due to lower heat transfer | Faster, thanks to combined heat modes |

| Heat Distribution | Even steam heat, less airflow | Uniform heat with active convection |

| Ideal For | Soft breads, buns, and delicate textures | Crusty breads like baguettes and artisan loaves |

| Energy Efficiency | Lower due to longer cooking time | Higher efficiency, less cooking time |

Introduction: Steaming vs Steam Convection in Bread Baking

Steaming and steam convection are two critical methods used in bread baking to enhance crust formation and crumb texture. Steaming introduces direct moisture to the dough surface, promoting a glossy crust and optimal oven spring, while steam convection combines steam with circulated hot air for more even heat distribution and crust development. Choosing between these methods impacts the final bread quality, texture, and baking efficiency.

How Traditional Steaming Works for Bread

Traditional steaming for bread involves introducing hot steam directly into the baking environment, which helps create a moist atmosphere essential for developing a crisp, shiny crust. The steam condenses on the dough surface, delaying crust formation and allowing the bread to expand fully during the initial baking phase.

This method contrasts with steam convection, where steam is circulated with heated air, promoting more even heat distribution but potentially reducing surface moisture retention. Traditional steaming's effectiveness lies in its ability to maintain high humidity levels that enhance crust texture and oven spring.

Understanding Steam Convection Ovens

Steam convection ovens combine steam injection with convection heat to create an ideal baking environment for bread, promoting a crisp crust and moist crumb. Understanding the difference between traditional steaming and steam convection helps bakers optimize texture and oven spring.

- Steam injection - Adds moisture to the oven, facilitating better crust formation while preventing dryness.

- Convection heat - Circulates hot air evenly around the bread, ensuring consistent baking and crust development.

- Temperature control - Maintains stable heat and humidity levels, crucial for balanced bread expansion and browning.

Key Differences Between Steaming and Steam Convection

Steaming involves cooking bread with direct steam injection, creating a moist environment that helps develop a shiny crust and soft crumb. Steam convection combines steam with hot air circulation, promoting even heat distribution and a slightly firmer crust texture.

Steaming alone maximizes moisture retention, ideal for artisan breads requiring a tender interior, while steam convection enhances browning and crust crispiness through efficient heat transfer. The key difference lies in steam convection's ability to balance moisture and airflow, producing consistent baking results.

Bread Crust: Effects of Each Method

Steaming creates a shiny, crisp crust by maintaining high humidity during the initial baking phase, preventing the dough surface from drying too quickly. Steam convection combines moist heat with air circulation, promoting a more evenly browned and thicker crust texture on bread.

- Steaming - Retains moisture on the dough surface, resulting in a glossy and soft crust initially.

- Steam Convection - Enhances Maillard reactions through hot air circulation, producing a darker, crunchier crust.

- Crust Thickness - Steam convection typically yields a thicker, more textured crust compared to pure steaming.

Texture and Moisture: Steaming vs Steam Convection

Steaming preserves the bread's internal moisture, creating a soft and tender crumb, while steam convection combines steam with hot air, producing a crust with a crispier texture. The enhanced moisture retention in traditional steaming results in a chewier crust compared to the drier, crunchier crust achieved with steam convection ovens.

- Moisture Retention - Steaming maintains higher internal moisture levels in bread, yielding a softer crumb.

- Crust Texture - Steam convection promotes a crisp, golden-brown crust by circulating hot air around the loaf.

- Crust Chewiness - Traditional steaming leads to a chewier crust due to sustained humidity during baking.

Choosing between steaming and steam convection depends on the desired balance between crumb softness and crust crunchiness.

Flavor Development in Steamed and Convection-Steamed Bread

Steaming bread produces a moist environment that enhances flavor development by preserving the bread's natural sugars and subtle aromas. Steam convection combines moisture with hot air circulation, intensifying caramelization and crust formation, which results in a richer, more complex flavor profile.

In steamed bread, the absence of dry heat limits Maillard reactions, leading to a softer crust and milder taste. Steam convection accelerates these chemical reactions by balancing moisture and heat, producing a more pronounced crust and deeper, roasted flavors. This method is preferred for artisanal breads where flavor complexity and texture are prioritized.

Equipment Needed for Each Method

Steaming bread requires a simple setup such as a pot with a lid and a heat source to generate consistent steam. Steam convection baking uses specialized ovens equipped with fans and steam injectors to circulate moist heat evenly around the dough. The equipment for steam convection is more advanced and designed to control humidity and temperature precisely, improving crust and texture quality.

Pros and Cons: Traditional Steaming vs Steam Convection

| Method | Pros | Cons |

|---|---|---|

| Traditional Steaming | Provides consistent moisture creating a glossy crust, helps achieve a chewy texture, and enhances oven spring in artisan bread. | Requires careful timing to avoid soggy crusts, may cause uneven heat distribution, and typically has longer baking times. |

| Steam Convection | Combines steam with circulating hot air for faster, more even baking, improves crust crispness, and reduces baking time significantly. | May result in drier crumb if steam is overused, equipment can be more expensive, and requires precise control to balance moisture and heat. |

Related Important Terms

Direct Steaming

Direct steaming injects moisture into the baking environment, creating a glossy crust and enhancing oven spring by gelatinizing the dough's surface more effectively than steam convection. This targeted moisture application ensures a crisp, thin crust and optimal crumb texture, critical for artisan bread quality.

Pulse Steaming

Pulse steaming enhances crust development and oven spring in bread baking by releasing controlled bursts of steam, improving heat transfer compared to continuous steam convection. This method optimizes moisture retention and surface gelatinization, resulting in a crispier crust and lighter crumb structure.

Steam Injection Bake

Steam Injection Bake enhances bread crust quality by delivering precise humidity and temperature control within the oven, promoting optimal crust formation and oven spring. Unlike traditional steaming methods or steam convection, steam injection ensures uniform steam distribution, preventing sogginess while maintaining a crisp, glossy crust essential for artisan bread.

Deck Oven Humidity Control

Deck oven humidity control influences bread crust development by regulating steam injection, where steaming creates a moist environment to enhance oven spring and crust softness, while steam convection circulates vapor evenly, ensuring consistent heat and moisture distribution for uniform baking. Optimizing steam timing and intensity in deck ovens improves crumb texture and crust color, balancing moisture retention and crust crispiness.

Vapor Phase Bake

Vapor phase baking utilizes steam to create a humid environment that enhances crust development and oven spring in bread, while steam convection combines steam with hot air circulation to promote even heat distribution and faster baking times. The vapor phase bake method emphasizes moisture retention without aggressive airflow, resulting in a glossy, crisp crust and improved crumb texture.

Steam Burst Technology

Steam Burst Technology enhances bread baking by delivering precise, high-intensity steam injections that improve crust development and oven spring compared to traditional steam convection methods. This targeted steam application creates a crisp, golden crust while maintaining a moist, airy crumb, optimizing texture and flavor in artisan bread.

Laminar Steam Flow

Laminar steam flow provides a controlled, uniform moisture environment essential for optimal crust formation in bread baking, enhancing crumb texture and surface sheen. Compared to steam convection, laminar steam flow minimizes turbulence, preventing uneven heat distribution and preserving the bread's structural integrity during the steaming process.

Hybrid Steam-Convection Cycle

The Hybrid Steam-Convection Cycle combines the moisture retention benefits of steaming with the even heat distribution of steam convection, resulting in crustier bread with a tender crumb. This method optimizes baking by using steam to enhance oven spring and convection heat to achieve uniform browning and texture.

Diffusive Steam Dispersion

Diffusive steam dispersion in steaming provides a uniform moisture distribution crucial for optimal bread crust formation, while steam convection relies on airflow mechanics that may cause uneven steam contact and inconsistent baking results. This controlled diffusion enhances dough expansion and crust texture by maintaining stable humidity and temperature levels throughout the baking process.

Steaming vs Steam Convection for bread. Infographic

cookingdiff.com

cookingdiff.com