Steaming uses direct contact with steam to cook food evenly and retain nutrients, while steam-infusion injects steam directly into the product for faster heat transfer and reduced cooking times. Steam-infusion enhances texture and flavor by rapidly heating food from within, resulting in a more consistent and efficient cooking process. This technology outperforms traditional steaming in both speed and energy efficiency, making it ideal for high-volume rapid cooking applications.

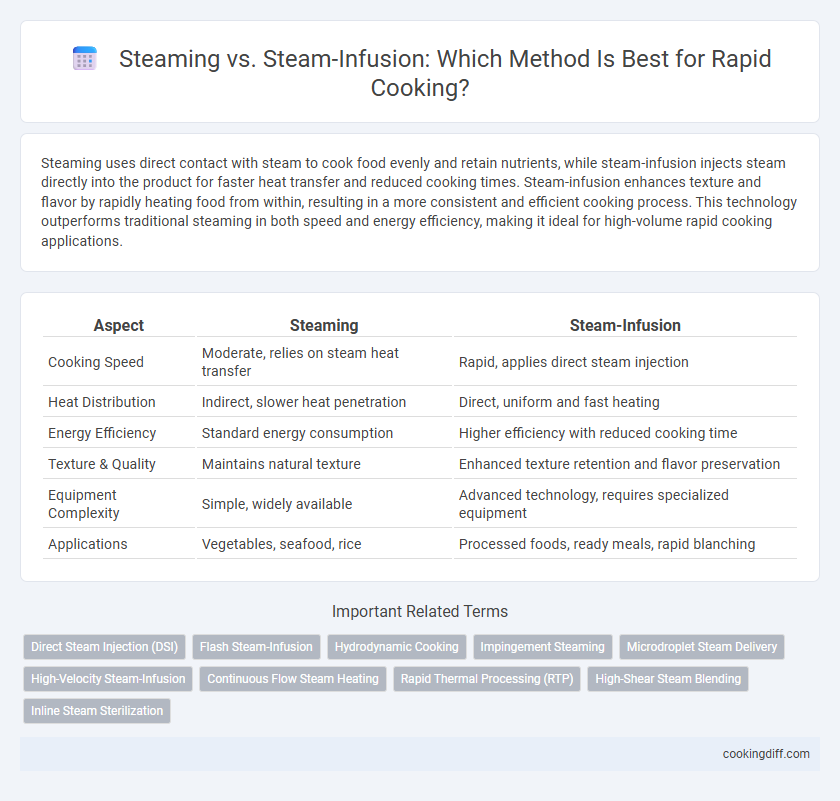

Table of Comparison

| Aspect | Steaming | Steam-Infusion |

|---|---|---|

| Cooking Speed | Moderate, relies on steam heat transfer | Rapid, applies direct steam injection |

| Heat Distribution | Indirect, slower heat penetration | Direct, uniform and fast heating |

| Energy Efficiency | Standard energy consumption | Higher efficiency with reduced cooking time |

| Texture & Quality | Maintains natural texture | Enhanced texture retention and flavor preservation |

| Equipment Complexity | Simple, widely available | Advanced technology, requires specialized equipment |

| Applications | Vegetables, seafood, rice | Processed foods, ready meals, rapid blanching |

Understanding Traditional Steaming in Cooking

Traditional steaming involves cooking food by exposing it to steam vapor at temperatures typically around 100degC, preserving nutrients and texture. This method relies on direct contact with steam, ensuring even heat distribution and minimal nutrient loss.

In contrast, steam-infusion technology rapidly cooks food by injecting steam directly into the product, reducing cooking time significantly. Understanding traditional steaming helps highlight the benefits of controlled, gentle heat in maintaining food quality during preparation.

What is Steam-Infusion? A Modern Approach

Steam-infusion is a modern cooking technique that utilizes high-velocity steam to rapidly cook food by directly injecting steam into the ingredients, enhancing heat transfer and reducing cooking time compared to traditional steaming. This method preserves flavor, texture, and nutrient content more effectively by minimizing water contact and exposure to high temperatures. Food producers in commercial kitchens prefer steam-infusion for its efficiency and ability to deliver consistent, high-quality results in rapid cooking processes.

Comparing Cooking Speeds: Steaming vs Steam-Infusion

How does the cooking speed of traditional steaming compare to steam-infusion methods? Traditional steaming typically takes longer as it relies on indirect heat transfer through steam, whereas steam-infusion uses high-velocity steam to penetrate food faster, significantly reducing cooking times. Steam-infusion can cut cooking times by up to 50%, optimizing efficiency in commercial kitchens and food processing.

Nutritional Retention: Which Method Wins?

Steaming preserves nutrients effectively by cooking food at lower temperatures and minimizing water contact, which prevents leaching of vitamins and minerals. Steam-infusion uses higher pressure and temperature, potentially causing slight nutrient degradation but offering faster cooking times.

Studies show traditional steaming maintains higher levels of water-soluble vitamins such as vitamin C and B-complex compared to steam-infusion. However, steam-infusion excels in nutrient retention for certain minerals due to shorter cooking durations. Choosing between these methods depends on balancing nutrient preservation with cooking speed requirements.

Energy Efficiency: Steam-Infusion vs Standard Steaming

Steam-infusion technology significantly reduces energy consumption compared to standard steaming by directly injecting steam into the food, leading to faster heat transfer. This rapid cooking method minimizes heat loss and shortens cooking times, enhancing overall energy efficiency.

- Reduced Energy Usage - Steam-infusion delivers steam directly into the product, reducing wasted energy typically lost in standard steaming processes.

- Faster Cooking Times - Accelerated heat transfer during steam-infusion decreases cooking duration, lowering total energy demands.

- Improved Thermal Efficiency - The controlled steam environment in steam-infusion systems maintains consistent temperatures, optimizing energy use compared to conventional steamers.

Flavor and Texture Differences Explained

| Steaming | Preserves natural flavors by cooking food gently with direct steam, resulting in a tender texture. Nutrient retention is high, enhancing both taste and mouthfeel. Ideal for vegetables and delicate proteins to maintain structural integrity. |

| Steam-Infusion | Uses pressurized steam to infuse flavors rapidly, achieving a more intense taste profile. The rapid heat transfer creates a unique texture that is often crispier or more evenly cooked. Suitable for foods requiring quick cooking without sacrificing moisture. |

Equipment Needed for Steaming and Steam-Infusion

Steaming requires basic equipment such as a pot with a lid, a steaming basket, and a heat source to produce steam. These tools are readily available and easy to use for cooking vegetables, fish, and other foods evenly with moist heat.

Steam-infusion equipment involves specialized machinery that injects high-pressure steam directly into food, enabling rapid cooking and enhanced flavor retention. This method requires investment in industrial-grade steam injectors and precise temperature controls to optimize cooking efficiency.

Versatility in the Kitchen: Applications of Both Methods

Steaming offers broad culinary versatility, suitable for vegetables, seafood, and delicate proteins, preserving nutrients and texture. Steam-infusion provides rapid heat transfer ideal for uniform cooking of dense foods and flavor infusion in broths and sauces.

- Steaming excels in gentle cooking - It retains moisture and nutrients, making it perfect for health-conscious meal preparation.

- Steam-infusion speeds up cooking times - High-pressure steam penetrates foods quickly, enhancing kitchen efficiency.

- Both methods support diverse cuisines - They adapt seamlessly for use in Asian, Western, and modernist cooking techniques.

Cost Considerations for Home and Commercial Use

Steaming offers a cost-effective solution for home kitchens with minimal upfront investment, while steam-infusion systems require higher initial costs but provide faster cooking times that can reduce energy expenses commercially. The choice between these methods depends on balancing equipment costs with operational savings in both domestic and business environments.

- Steaming equipment cost - Typically lower for home use, making it accessible for everyday cooking.

- Steam-infusion initial investment - Higher due to advanced technology and specialized machinery, suited for commercial kitchens.

- Energy efficiency - Steam-infusion can reduce cooking time significantly, lowering energy costs over time.

Home users prioritize affordability, whereas commercial operations focus on long-term cost efficiency and productivity.

Related Important Terms

Direct Steam Injection (DSI)

Direct Steam Injection (DSI) accelerates cooking by injecting steam directly into the food, ensuring rapid heat transfer and uniform temperature distribution, resulting in shorter cooking times compared to traditional steam-infused methods. This technique enhances moisture retention and nutrient preservation while reducing energy consumption, making it highly efficient for industrial and commercial food processing applications.

Flash Steam-Infusion

Flash Steam-Infusion accelerates cooking by directly injecting pressurized steam into food, resulting in faster heat transfer and reduced cooking times compared to traditional steaming methods. This technique enhances flavor retention and nutrient preservation due to its rapid and even cooking process.

Hydrodynamic Cooking

Hydrodynamic cooking using steam-infusion accelerates heat transfer by directly injecting steam into food, enabling rapid cooking with enhanced flavor retention and nutrient preservation compared to conventional steaming. This technique reduces cooking time and energy consumption while promoting uniform heat distribution through dynamic steam flow.

Impingement Steaming

Impingement steaming accelerates rapid cooking by directing high-velocity steam jets directly onto food surfaces, enhancing heat transfer and reducing cooking time compared to traditional steam-infusion methods. This technique ensures consistent texture and flavor retention by minimizing moisture loss and promoting uniform cooking throughout the product.

Microdroplet Steam Delivery

Microdroplet steam delivery enhances steaming by dispersing fine steam droplets directly onto food surfaces, accelerating heat transfer compared to traditional steam infusion methods. This rapid cooking technique improves texture retention and nutrient preservation while reducing overall cooking time.

High-Velocity Steam-Infusion

High-velocity steam-infusion uses powerful steam jets to rapidly penetrate food, reducing cooking times by up to 50% compared to traditional steaming while preserving nutrient density and texture. This method enhances heat transfer efficiency, enabling uniform cooking and energy savings in commercial kitchens.

Continuous Flow Steam Heating

Continuous flow steam heating enhances rapid cooking by delivering precise and uniform steam infusion, significantly reducing cooking time compared to traditional steaming methods. This technique ensures consistent heat distribution, improving product quality and energy efficiency in industrial food processing.

Rapid Thermal Processing (RTP)

Rapid Thermal Processing (RTP) leverages steam-infusion to achieve faster and more uniform heat transfer compared to conventional steaming, significantly reducing cooking times while preserving food quality. Steam-infusion systems circulate high-temperature steam directly through the product, enhancing heat penetration and accelerating thermal processing efficiency.

High-Shear Steam Blending

High-shear steam blending accelerates cooking by combining intense steam pressure with mechanical agitation, enhancing heat transfer and reducing cooking time compared to traditional steaming. This method ensures uniform temperature distribution and improved texture retention during rapid cooking processes.

Steaming vs Steam-Infusion for rapid cooking. Infographic

cookingdiff.com

cookingdiff.com