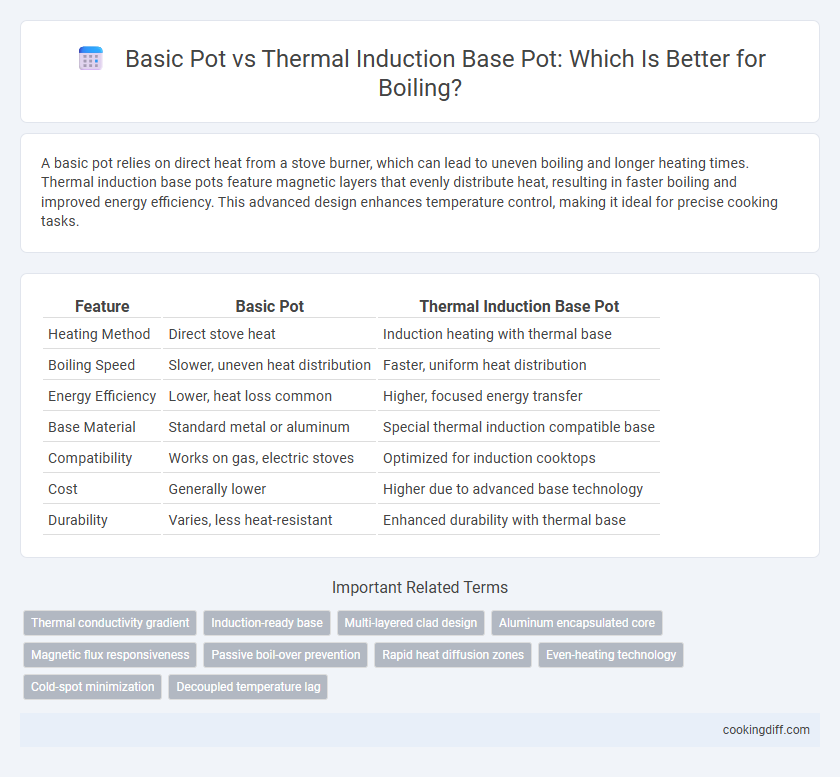

A basic pot relies on direct heat from a stove burner, which can lead to uneven boiling and longer heating times. Thermal induction base pots feature magnetic layers that evenly distribute heat, resulting in faster boiling and improved energy efficiency. This advanced design enhances temperature control, making it ideal for precise cooking tasks.

Table of Comparison

| Feature | Basic Pot | Thermal Induction Base Pot |

|---|---|---|

| Heating Method | Direct stove heat | Induction heating with thermal base |

| Boiling Speed | Slower, uneven heat distribution | Faster, uniform heat distribution |

| Energy Efficiency | Lower, heat loss common | Higher, focused energy transfer |

| Base Material | Standard metal or aluminum | Special thermal induction compatible base |

| Compatibility | Works on gas, electric stoves | Optimized for induction cooktops |

| Cost | Generally lower | Higher due to advanced base technology |

| Durability | Varies, less heat-resistant | Enhanced durability with thermal base |

Introduction to Boiling: Pot Basics

Boiling efficiency depends significantly on the pot's base material and design. Basic pots with traditional metal bases conduct heat comparably but often lose energy through uneven heat distribution. Thermal induction base pots enhance boiling speed and energy use by incorporating magnetic materials that optimize heat transfer directly to the pot's surface.

What is a Basic Pot?

A basic pot is typically made from materials like stainless steel, aluminum, or ceramic, and relies on direct heat transfer from the stove to boil water or cook food. Its efficiency depends on the pot's material and thickness, often resulting in uneven heating and longer boiling times compared to advanced cookware.

Basic pots lack specialized bases designed for induction cooktops, making them incompatible with thermal induction technology. This limitation affects energy consumption and cooking precision when compared to thermal induction base pots, which heat faster and more evenly.

Understanding Thermal Induction Base Pots

Thermal induction base pots use magnetic fields to generate heat directly within the pot's base, making them more energy-efficient for boiling compared to basic pots. These pots offer faster heating times and consistent temperature control, optimizing the boiling process for various cooking needs.

- Energy Efficiency - Thermal induction base pots convert up to 90% of energy into heat, reducing wasted energy compared to basic pots.

- Faster Boiling - Induction technology allows water to reach boiling point up to 3 times faster than traditional pots.

- Temperature Precision - Precise control minimizes overheating and maintains steady boiling without continuous manual adjustments.

Understanding the advantages of thermal induction base pots helps select cookware that enhances boiling performance while saving energy.

Heat Distribution Differences in Boiling

Basic pots often have uneven heat distribution, causing hotspots that can lead to inconsistent boiling and increased cooking time. Thermal induction base pots utilize magnetic fields to generate heat uniformly across the base, resulting in faster and more efficient boiling.

Heat distribution in thermal induction base pots ensures a consistent temperature, reducing the risk of food burning or sticking. The direct transfer of electromagnetic energy improves energy efficiency compared to traditional basic pots that rely on conduction from the stove. This consistent heating optimizes boiling performance, making thermal induction pots ideal for precise cooking tasks.

Energy Efficiency: Basic vs Thermal Induction Pots

Basic pots rely on direct heat transfer from the stove burner, often resulting in uneven heating and higher energy consumption during boiling. Thermal induction base pots feature magnetic bases that ensure rapid and uniform heat distribution, significantly reducing energy usage by targeting heat directly to the pot.

Energy efficiency tests show thermal induction pots can boil water up to 50% faster than basic pots, translating to lower electricity or gas bills. This efficiency not only conserves energy but also minimizes heat loss, making thermal induction pots a more sustainable choice for everyday cooking.

Boiling Time Comparison: Which Heats Faster?

Thermal induction base pots significantly reduce boiling time due to their enhanced magnetic conductivity, which allows faster and more efficient heat transfer compared to basic pots with conventional metal bases. Basic pots typically rely on slower conduction and convection processes, leading to longer heating durations and increased energy consumption. Studies show that thermal induction base pots can boil water up to 30-40% faster, making them ideal for energy-saving and time-efficient cooking.

Durability and Maintenance Considerations

Basic pots often feature simpler materials that may warp or degrade over time with frequent boiling, while thermal induction base pots utilize advanced alloys enhancing resilience against heat damage. Maintenance for basic pots typically requires more frequent replacement due to wear, whereas thermal induction base pots offer easier cleaning and longer lifespan under consistent use.

- Durability - Thermal induction base pots resist warping and corrosion better than basic pots due to higher quality metal construction.

- Maintenance - Basic pots may require more vigilant care to avoid residual staining and damage from harsh cleaning methods.

- Longevity - Thermal induction base pots maintain structural integrity longer, reducing the need for frequent replacements.

Suitability for Different Heating Surfaces

Which pot base is more suitable for various heating surfaces, a basic pot or a thermal induction base pot? Basic pots perform well on open flame and electric coil stoves but may struggle with induction cooktops due to lack of magnetic compatibility. Thermal induction base pots are specifically designed to work efficiently on induction surfaces, providing faster and more even heat distribution across all types of stovetops.

Cost Effectiveness for Everyday Boiling

Basic pots are generally more affordable upfront, making them a cost-effective choice for everyday boiling tasks. Thermal induction base pots may have a higher initial cost but offer energy savings that reduce expenses over time.

- Initial Cost - Basic pots typically cost less at purchase, benefiting budget-conscious users.

- Energy Efficiency - Thermal induction base pots heat faster and use less energy, lowering utility bills.

- Long-Term Savings - The energy-efficient design of thermal induction pots can offset their higher price through reduced energy consumption during frequent boiling.

Related Important Terms

Thermal conductivity gradient

A thermal induction base pot features a specialized multi-layered construction that enhances thermal conductivity gradient, allowing rapid and even heat distribution during boiling compared to basic pots with single-layer bottoms. This advanced thermal design reduces energy consumption and prevents hotspots, ensuring consistent boiling performance and improved cooking efficiency.

Induction-ready base

Induction-ready base pots feature a magnetic stainless steel layer that ensures rapid and even heat distribution on induction cooktops, significantly reducing boiling time compared to basic pots with aluminum or non-magnetic bases. These thermal induction base pots also improve energy efficiency and maintain consistent temperature control, enhancing cooking performance for boiling tasks.

Multi-layered clad design

A basic pot typically features a single-layer base that offers uneven heat distribution, resulting in hotspots during boiling. In contrast, a thermal induction base pot utilizes a multi-layered clad design combining aluminum and stainless steel layers, ensuring rapid, uniform heat conduction and improved boiling efficiency.

Aluminum encapsulated core

Aluminum encapsulated core in thermal induction base pots ensures faster and more uniform heat distribution compared to basic pots, reducing boiling time and energy consumption. This core design enhances compatibility with induction cooktops, providing efficient temperature control and preventing hotspots during boiling.

Magnetic flux responsiveness

Thermal induction base pots are engineered with ferromagnetic materials that maximize magnetic flux responsiveness, ensuring rapid and even heat distribution during boiling. Basic pots lack this optimized magnetic base, resulting in slower heat transfer and less energy-efficient boiling performance.

Passive boil-over prevention

A thermal induction base pot offers superior passive boil-over prevention compared to a basic pot by providing rapid, even heat distribution that minimizes hotspots causing sudden boil-overs. The enhanced thermal conductivity and precise temperature control of induction bases reduce the risk of overflowing, improving safety and efficiency during boiling tasks.

Rapid heat diffusion zones

Thermal induction base pots feature specialized rapid heat diffusion zones composed of magnetic stainless steel layers that enable uniform and efficient heat distribution, significantly reducing boiling time compared to basic pots with standard aluminum or copper bases. These zones concentrate heat precisely at the pot's bottom, minimizing energy loss and enhancing overall thermal conductivity for faster and more consistent boiling performance.

Even-heating technology

Thermal induction base pots utilize advanced even-heating technology, distributing heat uniformly across the surface to prevent hotspots and ensure consistent boiling. In contrast, basic pots often have uneven heat distribution, leading to longer boiling times and potential burning at the base.

Cold-spot minimization

Thermal induction base pots significantly minimize cold spots by ensuring uniform heat distribution across the entire base, unlike basic pots that often have uneven heating leading to localized boiling inefficiencies. This optimized heat transfer enhances boiling performance, reduces energy consumption, and prevents food from sticking or burning.

Basic pot vs Thermal induction base pot for boiling. Infographic

cookingdiff.com

cookingdiff.com