Boiling stocks extracts flavors quickly but can cause volatile compounds to dissipate, potentially resulting in a less nuanced taste. Vacuum infusion preserves delicate aromas and subtle flavors by gently drawing liquids into ingredients without heat-induced evaporation. Comparing both methods, vacuum infusion offers a more controlled extraction process, enhancing complexity while maintaining clarity in stock preparation.

Table of Comparison

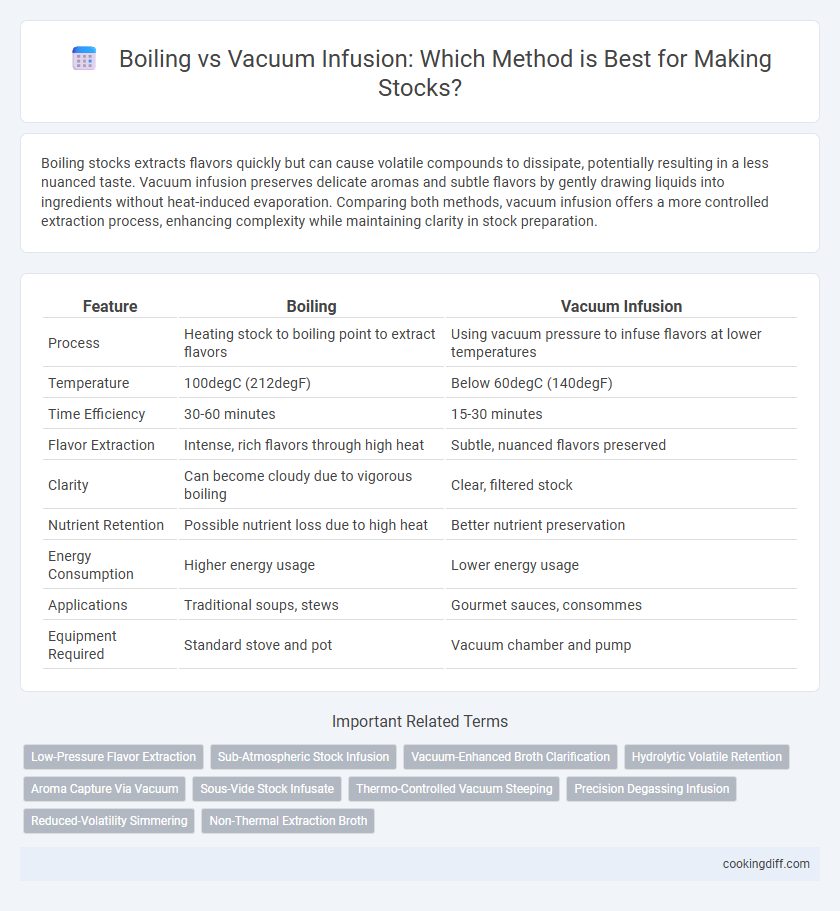

| Feature | Boiling | Vacuum Infusion |

|---|---|---|

| Process | Heating stock to boiling point to extract flavors | Using vacuum pressure to infuse flavors at lower temperatures |

| Temperature | 100degC (212degF) | Below 60degC (140degF) |

| Time Efficiency | 30-60 minutes | 15-30 minutes |

| Flavor Extraction | Intense, rich flavors through high heat | Subtle, nuanced flavors preserved |

| Clarity | Can become cloudy due to vigorous boiling | Clear, filtered stock |

| Nutrient Retention | Possible nutrient loss due to high heat | Better nutrient preservation |

| Energy Consumption | Higher energy usage | Lower energy usage |

| Applications | Traditional soups, stews | Gourmet sauces, consommes |

| Equipment Required | Standard stove and pot | Vacuum chamber and pump |

Understanding Boiling: Traditional Stock-Making

What are the key differences between boiling and vacuum infusion in traditional stock-making methods? Boiling involves simmering ingredients at 100degC to extract flavors and nutrients through heat and agitation, resulting in a rich, concentrated broth. Vacuum infusion uses low pressure to draw flavors out at lower temperatures, preserving delicate aromas but requiring specialized equipment.

Introduction to Vacuum Infusion in Stock Preparation

Vacuum infusion in stock preparation utilizes reduced pressure to gently extract flavors and nutrients, preserving delicate compounds that might degrade under high heat. This method enhances clarity and depth of flavor without the vigorous agitation typical of boiling. Employing vacuum infusion can produce cleaner, more nuanced stocks ideal for gourmet culinary applications.

Temperature Control: Boiling vs Vacuum Infusion

Boiling maintains a constant temperature of 100degC at sea level, ensuring rapid extraction but risking the loss of volatile flavors in stocks. Vacuum infusion operates at lower temperatures by reducing pressure, preserving delicate aromas and achieving infusion without overheating.

- Boiling temperature consistency - Boiling stocks consistently reach 100degC, which accelerates flavor extraction but can degrade sensitive compounds.

- Vacuum infusion temperature control - Vacuum infusion lowers the boiling point, allowing stock to be cooked at temperatures between 60degC and 80degC, preserving nuanced flavors.

- Flavor preservation - Lower temperatures in vacuum infusion minimize flavor loss compared to the harsher thermal environment of boiling.

Flavor Extraction Efficiency Compared

Boiling extracts flavor compounds from stocks by applying high heat, which rapidly breaks down ingredients but may cause some volatile aromatics to dissipate. Vacuum infusion operates at lower temperatures, enhancing flavor extraction efficiency by preserving delicate volatile compounds and facilitating deeper penetration of flavors.

Studies indicate vacuum infusion retains up to 30% more aromatic molecules compared to traditional boiling, resulting in richer and more complex stock profiles. This method also reduces cooking time and energy consumption while maximizing extraction of gelatin, amino acids, and essential oils crucial for robust stocks.

Nutrient Retention: Which Method Wins?

Vacuum infusion preserves more vitamins and minerals in stocks compared to traditional boiling, which often causes nutrient loss through evaporation and heat degradation. This method enhances nutrient retention by infusing ingredients under reduced pressure, minimizing exposure to high temperatures and oxygen.

- Nutrient Preservation - Vacuum infusion retains up to 30% more vitamins like vitamin C and B-complex compared to boiling.

- Flavor Concentration - Reduced oxidation during vacuum infusion maintains delicate flavors and essential oils in the stock.

- Health Benefits - Stocks made with vacuum infusion contain higher antioxidant levels, contributing to better health outcomes.

Texture and Clarity of Stock: A Side-by-Side Analysis

Boiling stock results in a cloudy appearance due to vigorous agitation that breaks down collagen and fat, negatively impacting clarity. The texture tends to be gelatinous but less refined, as prolonged high heat can cause proteins to coagulate unevenly.

Vacuum infusion preserves clarity by gently extracting flavors at lower temperatures, minimizing fat emulsification and particulate disturbance. This method produces a smoother texture with a cleaner mouthfeel, enhancing the overall quality of the stock.

Cooking Time: Speed and Convenience

| Boiling | Typically requires 30 to 90 minutes to extract flavors from stocks, depending on ingredients and volume. |

| Vacuum Infusion | Accelerates extraction process to as little as 30 minutes by enhancing flavor infusion under reduced pressure. |

| Speed and Convenience | Boiling is simple but time-consuming, while vacuum infusion offers faster cooking times with efficient flavor extraction, ideal for time-sensitive cooking environments. |

Equipment Needed: Accessibility and Practicality

Boiling requires minimal equipment, typically just a pot and heat source, making it highly accessible and practical for most kitchens. Vacuum infusion demands specialized apparatus such as vacuum chambers and pumps, which can be costly and less accessible for everyday users. The simplicity of boiling equipment often outweighs the precision benefits of vacuum infusion in stock preparation for home cooks.

Consistency of Results: Reliability in the Kitchen

Boiling stocks can lead to uneven extraction of flavors due to fluctuating temperatures, while vacuum infusion maintains a stable environment for consistent results. The reliability of vacuum infusion in controlling infusion parameters surpasses traditional boiling methods in the kitchen.

- Boiling causes variability - Rapid temperature changes can affect the consistency of the stock's flavor profile.

- Vacuum infusion controls flavor extraction - Precise pressure regulation ensures uniform infusion of ingredients.

- Reliability impacts kitchen efficiency - Consistent stock quality reduces trial-and-error in recipes, saving time and resources.

Vacuum infusion offers superior consistency and reliability over boiling for professional and home cooks seeking dependable stock results.

Related Important Terms

Low-Pressure Flavor Extraction

Boiling extracts flavors from stocks through high-temperature vaporization, which can degrade delicate aromatics and result in a less nuanced profile. Vacuum infusion uses low-pressure conditions to draw out flavors gently, preserving subtle compounds and enhancing the overall depth and clarity of the stock.

Sub-Atmospheric Stock Infusion

Sub-atmospheric stock infusion uses vacuum pressure to extract flavors efficiently at lower temperatures, preserving delicate aromatic compounds that traditional boiling can degrade. This method enhances clarity and depth in stocks by minimizing oxidation and nutrient loss associated with prolonged boiling.

Vacuum-Enhanced Broth Clarification

Vacuum infusion accelerates stock cooking by lowering boiling points, enabling efficient extraction of flavors and aromas without overcooking ingredients. This vacuum-enhanced broth clarification results in clearer, more intensely flavored stocks compared to traditional boiling methods.

Hydrolytic Volatile Retention

Boiling causes significant hydrolytic volatile loss in stocks due to prolonged exposure to high temperatures, which degrades delicate flavor compounds. Vacuum infusion preserves hydrolytic volatiles by reducing the boiling point and minimizing thermal degradation, resulting in richer, more aromatic stock profiles.

Aroma Capture Via Vacuum

Vacuum infusion effectively captures and preserves the volatile aromatic compounds in stocks by reducing atmospheric pressure, allowing extraction at lower temperatures than boiling. This method minimizes aroma loss and enhances flavor concentration, resulting in a richer, more fragrant stock.

Sous-Vide Stock Infusate

Sous-vide stock infusate maintains precise temperature control to extract deep flavors without overcooking, preserving delicate aromatics better than traditional boiling. Vacuum infusion enhances infusion efficiency by removing air pockets, allowing faster and more uniform flavor absorption compared to conventional boiling methods.

Thermo-Controlled Vacuum Steeping

Thermo-controlled vacuum steeping combines the benefits of boiling and vacuum infusion by precisely regulating temperature and pressure to extract maximum flavor and nutrients from stocks without overcooking. This method enhances the clarity and depth of the stock while preserving delicate aromas, outperforming traditional boiling which often leads to nutrient loss and cloudiness.

Precision Degassing Infusion

Precision Degassing Infusion outperforms traditional boiling by enabling controlled vacuum pressure to remove dissolved gases from stocks, enhancing clarity and flavor concentration. This method prevents oxidation and off-flavors commonly caused by the high temperatures of boiling, ensuring a purer and more refined infusion.

Reduced-Volatility Simmering

Boiling stock causes rapid evaporation and aggressive agitation, increasing volatility and altering flavor profiles, whereas vacuum infusion enables reduced-volatility simmering by lowering the boiling point, preserving delicate aromas and nutrients. This controlled, gentle extraction method results in clearer, more balanced stocks with enhanced depth and subtlety.

Boiling vs Vacuum Infusion for Stocks. Infographic

cookingdiff.com

cookingdiff.com