Boiling rapidly heats ingredients, breaking down fibers and enhancing flavors through direct contact with water, while vacuum-sealing preserves freshness and locks in natural juices by removing air and preventing oxidation. Vacuum-sealing is ideal for marinating and slow cooking, maintaining texture and nutrients without overcooking, whereas boiling is best for quick softening and flavor infusion. Choosing between boiling and vacuum-sealing depends on the desired texture, flavor intensity, and nutrient retention in ingredient preparation.

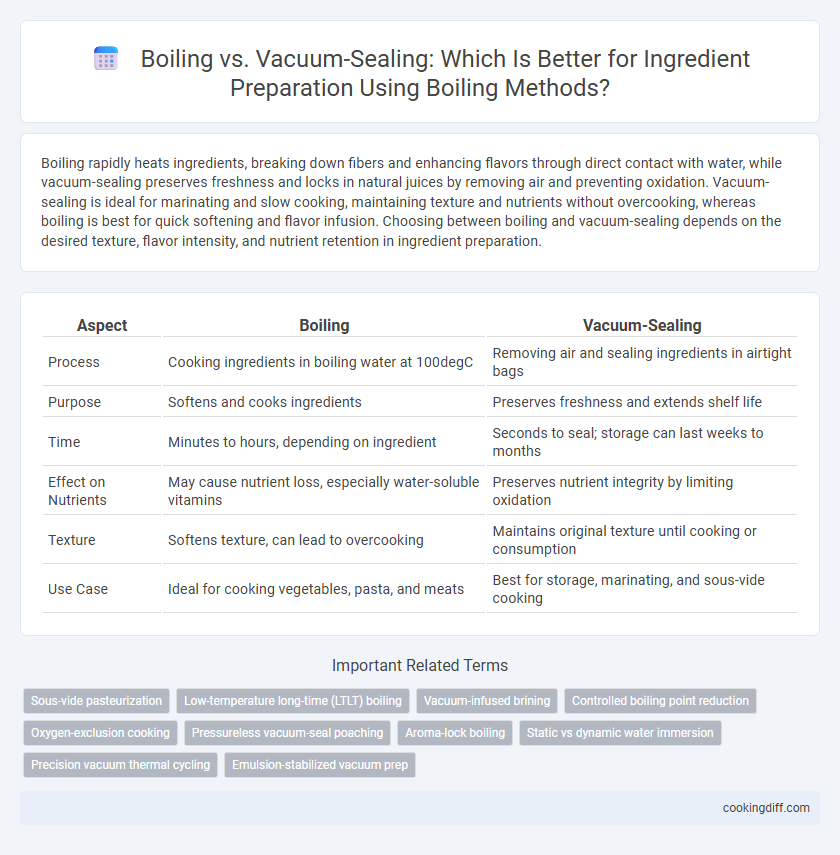

Table of Comparison

| Aspect | Boiling | Vacuum-Sealing |

|---|---|---|

| Process | Cooking ingredients in boiling water at 100degC | Removing air and sealing ingredients in airtight bags |

| Purpose | Softens and cooks ingredients | Preserves freshness and extends shelf life |

| Time | Minutes to hours, depending on ingredient | Seconds to seal; storage can last weeks to months |

| Effect on Nutrients | May cause nutrient loss, especially water-soluble vitamins | Preserves nutrient integrity by limiting oxidation |

| Texture | Softens texture, can lead to overcooking | Maintains original texture until cooking or consumption |

| Use Case | Ideal for cooking vegetables, pasta, and meats | Best for storage, marinating, and sous-vide cooking |

Introduction to Ingredient Preparation Methods

Boiling and vacuum-sealing are two fundamental methods for preparing ingredients, each impacting texture and flavor differently. Boiling uses high temperatures to cook ingredients in water, while vacuum-sealing preserves freshness by removing air and sealing ingredients airtight.

- Boiling - efficiently softens ingredients through heat and moisture, ideal for soups and stews.

- Vacuum-sealing - extends shelf life by preventing oxidation and preserving natural flavors.

- Preparation focus - boiling alters ingredient structure, whereas vacuum-sealing maintains raw state until cooking.

Choosing the appropriate preparation method depends on the desired outcome in texture, flavor, and preservation.

Understanding Boiling: Techniques and Benefits

Boiling involves heating ingredients in water at 100degC to soften textures and enhance flavors through heat-induced chemical changes. This method efficiently breaks down fibers and activates enzymes, improving digestibility and nutrient availability.

Vacuum-sealing preserves freshness by removing air to prevent oxidation, but boiling uniquely alters food properties via thermal processing. Techniques such as blanching or simmering control cooking intensity for desired texture and taste. Understanding boiling's role in ingredient preparation helps optimize flavor profiles and nutrient retention.

What is Vacuum-Sealing in Culinary Prep?

| Vacuum-sealing in culinary preparation involves removing air from packaging around ingredients, which slows oxidation and preserves freshness. |

| This method prevents microbial growth by creating a low-oxygen environment, extending shelf life compared to traditional boiling. |

| Vacuum-sealed ingredients maintain texture and flavor better as they are not exposed to high-temperature water that can break down cellular structures. |

Flavor Retention: Boiling vs Vacuum-Sealing

Boiling often leads to significant flavor loss as volatile compounds evaporate during the high-heat process. Vacuum-sealing preserves the natural flavors by minimizing air exposure and retaining aromatic compounds within the sealed environment. Studies show vacuum-sealing maintains up to 90% more flavor compared to traditional boiling methods.

Nutrient Preservation: Comparing Methods

Boiling often leads to significant nutrient loss, particularly water-soluble vitamins like vitamin C and B-complex, due to high temperatures and water exposure. In contrast, vacuum-sealing minimizes oxidation and nutrient degradation by reducing air exposure, preserving essential vitamins and antioxidants in ingredients.

Vacuum-sealing also slows enzymatic activity and microbial growth without heat, maintaining nutrient integrity better than boiling. This method is especially beneficial for delicate ingredients where nutrient preservation is critical for flavor and nutritional value.

Texture and Consistency: Impact of Preparation Techniques

Boiling ingredients typically results in a softer texture and can cause some loss of moisture, affecting consistency. Vacuum-sealing preserves texture by minimizing oxidation and retaining juices, leading to more uniform consistency in prepared ingredients.

- Boiling softens ingredients - This method breaks down cell walls, resulting in a tender but sometimes mushy texture.

- Vacuum-sealing retains moisture - By sealing ingredients airtight, it prevents moisture loss and maintains firmness.

- Impact on consistency - Boiling can dilute flavors and create variable texture, while vacuum-sealing ensures consistent texture and flavor retention.

Safety and Shelf Life: Which Method Wins?

Boiling effectively eliminates harmful bacteria by reaching high temperatures, enhancing ingredient safety but may degrade some nutrients. Vacuum-sealing extends shelf life by removing air, which slows oxidation and microbial growth without heat exposure, preserving freshness longer.

- Boiling Safety - High temperatures during boiling ensure bacteria and pathogens are destroyed, reducing foodborne illness risks.

- Vacuum-Sealing Shelf Life - Removing oxygen inhibits spoilage organisms, significantly prolonging storage time of ingredients.

- Nutrient Preservation - Vacuum-sealing maintains nutritional quality better than boiling, which can cause nutrient loss through heat.

Equipment and Cost Considerations

Boiling requires basic kitchen equipment such as pots and stoves, which are widely available and cost-effective for most households. In contrast, vacuum-sealing demands specialized machines and vacuum bags, resulting in higher upfront investment and maintenance expenses.

Boiling incurs minimal ongoing costs, primarily energy consumption, while vacuum-sealing involves recurring expenses for replacement bags and potential machine servicing. The choice between methods depends on budget constraints and long-term usage goals in ingredient preparation.

Environmental Impact: Boiling and Vacuum-Sealing

How does the environmental impact of boiling compare to vacuum-sealing in ingredient preparation? Boiling consumes significant energy due to prolonged heating, contributing to higher carbon emissions. Vacuum-sealing uses minimal energy for sealing and allows longer preservation, reducing food waste and overall environmental footprint.

Related Important Terms

Sous-vide pasteurization

Boiling rapidly heats ingredients to a high temperature, but sous-vide pasteurization using vacuum-sealing precisely controls temperature and time, ensuring even cooking and enhanced flavor retention while effectively eliminating pathogens. Vacuum-sealing prevents moisture loss and oxidation, maintaining ingredient texture and nutritional quality compared to the harsher, less controlled boiling method.

Low-temperature long-time (LTLT) boiling

Low-temperature long-time (LTLT) boiling gently heats ingredients at temperatures typically between 60-85degC, preserving texture, flavor, and nutrients better than traditional boiling methods. Vacuum-sealing complements LTLT boiling by minimizing oxidation and moisture loss, enhancing ingredient consistency and extending shelf life during preparation.

Vacuum-infused brining

Vacuum-infused brining enhances flavor penetration and reduces marination time by using a vacuum chamber to open ingredient pores and infuse brine more effectively compared to traditional boiling methods. This technique preserves texture and nutrients, resulting in juicier, more evenly seasoned ingredients without the risk of overcooking.

Controlled boiling point reduction

Controlled boiling point reduction in vacuum-sealing allows precise temperature management by lowering the boiling point of water, which preserves nutrients and flavors better than traditional boiling methods. This technique enhances ingredient preparation by minimizing thermal degradation and accelerating cooking times under reduced pressure conditions.

Oxygen-exclusion cooking

Boiling rapidly heats ingredients in water at 100degC, promoting nutrient loss and oxidation, whereas vacuum-sealing removes oxygen, significantly reducing oxidative degradation and preserving flavor and nutrients during cooking. Oxygen-exclusion cooking via vacuum-sealing extends ingredient shelf life and maintains texture by minimizing microbial growth compared to traditional boiling methods.

Pressureless vacuum-seal poaching

Pressureless vacuum-seal poaching preserves the natural flavors and nutrients of ingredients by cooking them gently at low temperatures without added pressure, unlike boiling which often results in nutrient loss and flavor dilution. This method enhances texture and moisture retention while maintaining the ingredient's integrity through precise temperature control in a sealed environment.

Aroma-lock boiling

Aroma-lock boiling preserves the natural flavors and aromas of ingredients by boiling them in a sealed environment that traps volatile compounds, enhancing taste intensity. Unlike vacuum-sealing, which removes air before storage, aroma-lock boiling actively maintains aroma integrity during cooking, resulting in richer, more flavorful dishes.

Static vs dynamic water immersion

Boiling involves dynamic water immersion where high-temperature water rapidly transfers heat to ingredients, accelerating cooking and nutrient breakdown. Vacuum-sealing uses static water immersion at controlled lower temperatures, preserving flavor and texture by minimizing oxidation and moisture loss during ingredient preparation.

Precision vacuum thermal cycling

Precision vacuum thermal cycling leverages controlled vacuum environments to precisely regulate ingredient temperature and moisture levels, reducing oxidation and preserving nutrient integrity compared to traditional boiling methods. This technique ensures uniform ingredient preparation by alternating vacuum pressure and temperature cycles, enhancing flavor extraction and texture without the nutrient loss typical of boiling.

Boiling vs Vacuum-sealing for ingredient preparation. Infographic

cookingdiff.com

cookingdiff.com