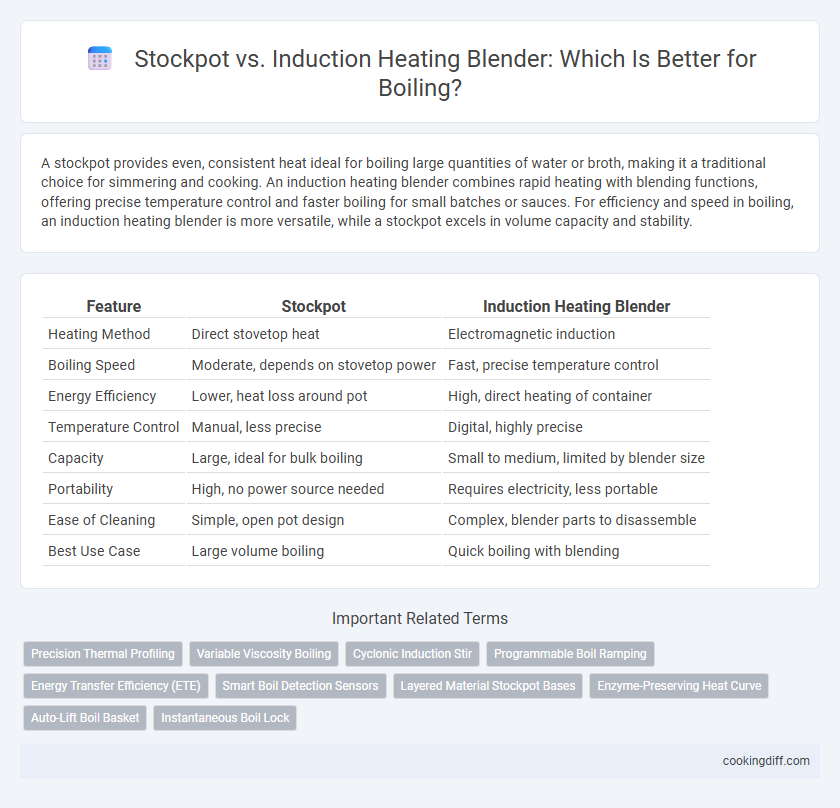

A stockpot provides even, consistent heat ideal for boiling large quantities of water or broth, making it a traditional choice for simmering and cooking. An induction heating blender combines rapid heating with blending functions, offering precise temperature control and faster boiling for small batches or sauces. For efficiency and speed in boiling, an induction heating blender is more versatile, while a stockpot excels in volume capacity and stability.

Table of Comparison

| Feature | Stockpot | Induction Heating Blender |

|---|---|---|

| Heating Method | Direct stovetop heat | Electromagnetic induction |

| Boiling Speed | Moderate, depends on stovetop power | Fast, precise temperature control |

| Energy Efficiency | Lower, heat loss around pot | High, direct heating of container |

| Temperature Control | Manual, less precise | Digital, highly precise |

| Capacity | Large, ideal for bulk boiling | Small to medium, limited by blender size |

| Portability | High, no power source needed | Requires electricity, less portable |

| Ease of Cleaning | Simple, open pot design | Complex, blender parts to disassemble |

| Best Use Case | Large volume boiling | Quick boiling with blending |

Introduction to Boiling: Stockpot vs Induction Heating Blender

Boiling is a fundamental cooking process where liquid reaches 100degC, causing vigorous bubbling and steam release. Traditional stockpots excel in boiling large quantities efficiently on gas or electric stovetops.

Induction heating blenders offer precise temperature control and rapid heating, making them ideal for small-batch boiling tasks. Unlike stockpots, induction blenders combine boiling with blending, streamlining preparation of soups and sauces. Energy efficiency and safety features in induction devices enhance cooking convenience and reduce heat loss during boiling.

How Stockpots Work for Boiling

Stockpots are designed with thick, heavy bottoms that provide even heat distribution, making them ideal for boiling large quantities of water or liquids. Their construction, often from stainless steel or aluminum, allows for efficient heat retention and helps maintain a consistent temperature throughout the boiling process. Unlike induction heating blenders, stockpots rely on direct flame or electric stove heat, which offers more precise control over boiling intensity for recipes requiring extended simmering or rapid boiling.

Induction Heating Blenders: Technology and Functionality

Induction heating blenders utilize electromagnetic fields to generate heat directly within the container, enabling rapid and precise temperature control for boiling liquids. This technology minimizes heat loss and enhances energy efficiency compared to traditional stockpots that rely on external heating sources.

The induction heating system allows for seamless temperature adjustments, which is ideal for delicate boiling processes such as making sauces or infusions. Functionality includes integrated sensors that monitor temperature and blending speed to prevent scorching and ensure uniform heat distribution.

Boiling Speed: Stockpot Compared to Induction Blender

Stockpots generally take longer to reach boiling point compared to induction heating blenders, which use electromagnetic energy for faster heat transfer. The induction blender's rapid heating reduces overall boiling time, enhancing efficiency in cooking processes.

- Stockpot boiling speed - Traditional stockpots rely on conduction through the pot material, resulting in slower heat-up times.

- Induction blender heating - Induction blenders generate heat directly in the cookware, enabling quicker boiling.

- Energy efficiency - Induction heating minimizes heat loss, leading to faster and more energy-efficient boiling compared to stockpots.

Temperature Control and Consistency

Stockpots provide reliable boiling with consistent heat distribution but lack precise temperature control compared to induction heating blenders. Induction heating blenders offer rapid temperature adjustments, ensuring exact boiling points and uniform heat for delicate recipes.

- Temperature Precision - Induction heating blenders allow for accurate temperature settings, essential for controlled boiling processes.

- Heat Distribution - Stockpots ensure even heat across large volumes, reducing hotspots during prolonged boiling.

- Consistency - Induction blenders maintain steady temperatures with real-time adjustments, preventing temperature fluctuations.

Choosing between the two depends on the need for precise temperature control versus volume capacity and heat consistency.

Energy Efficiency in Boiling: A Comparative Analysis

| Appliance | Energy Efficiency in Boiling | Key Features |

|---|---|---|

| Stockpot | Moderate efficiency; heat loss occurs due to indirect heating on gas or electric stovetops. | Large capacity, suitable for boiling large volumes, but slower to reach boiling point and retains heat less efficiently. |

| Induction Heating Blender | High efficiency; direct electromagnetic heating reduces energy wastage and quickly achieves boiling. | Rapid temperature control, precise heat application, and compact design optimize energy use for boiling smaller volumes. |

Safety Features: Stockpot vs Induction Heating Blender

Which option offers better safety features for boiling, a stockpot or an induction heating blender? Induction heating blenders provide precise temperature control and automatic shut-off functions to prevent overheating and burns. Stockpots, while generally sturdy, lack these advanced safety mechanisms, relying more on user vigilance during boiling.

Cleaning and Maintenance Differences

Stockpots made from stainless steel or enamel-coated materials generally require simple cleaning with warm soapy water and occasional descaling to maintain their surface integrity. In contrast, induction heating blenders feature non-stick or glass jars that need gentle hand washing or dishwasher-safe cleaning to avoid damaging sensitive components.

Stockpots often withstand abrasive scrubbing and metal utensils without damage, making them durable and low-maintenance for boiling tasks. Induction heating blenders require careful maintenance of electrical parts and heating coils, with strict adherence to manufacturer cleaning instructions to prevent malfunction or reduced efficiency.

Practical Applications: Best Uses for Each Method

Stockpots provide consistent, even heat ideal for simmering large quantities of soups and stews, while induction heating blenders offer rapid temperature control suited for precise boiling and blending tasks. Each method serves distinct practical purposes in culinary preparation depending on the volume and temperature sensitivity of the ingredients.

- Stockpot for Large Volumes - Optimal for boiling large batches due to its capacity and uniform heat distribution.

- Induction Heating Blender for Speed - Delivers quick temperature adjustments, making it efficient for fast boiling and blending.

- Heat Sensitivity Control - Induction heating blenders allow precise control perfect for delicate sauces or emulsions.

Related Important Terms

Precision Thermal Profiling

Stockpots provide broad, consistent heat distribution ideal for boiling large volumes, yet their thermal profile lacks the precise temperature control found in induction heating blenders. Induction heating blenders enable exact thermal profiling by rapidly adjusting heat levels, ensuring precise boiling points and reducing the risk of overheating or undercooking liquids.

Variable Viscosity Boiling

Stockpots provide uniform heat distribution essential for boiling liquids with variable viscosity, ensuring consistent temperature gradients and preventing hotspots during prolonged simmering. Induction heating blenders offer rapid temperature adjustments and precise control, ideal for variable viscosity boiling processes requiring quick viscosity changes and thorough mixing.

Cyclonic Induction Stir

The Cyclonic Induction Stir in induction heating blenders offers precise temperature control and rapid, uniform boiling compared to traditional stockpots, minimizing hotspots and scorching. This technology enhances energy efficiency and reduces cooking time while maintaining consistent boiling results in various liquid preparations.

Programmable Boil Ramping

A stockpot offers direct, consistent heat ideal for simmering and boiling large volumes of liquid, while an induction heating blender with programmable boil ramping provides precise temperature control and gradual heat increases to prevent scorching and ensure uniform heating. Programmable boil ramping technology in induction blenders enhances efficiency by automatically adjusting heat levels, optimizing cooking times, and preserving nutritional content during boiling processes.

Energy Transfer Efficiency (ETE)

Stockpots typically have lower Energy Transfer Efficiency (ETE) due to heat loss around the pot's sides and bottom, whereas induction heating blenders transfer energy directly to the cooking vessel through electromagnetic fields, achieving ETE values up to 90%. Induction technology minimizes wasted heat, resulting in faster boiling times and reduced energy consumption compared to conventional stockpots on gas or electric stoves.

Smart Boil Detection Sensors

Stockpots equipped with smart boil detection sensors provide precise temperature control, preventing overflows and ensuring efficient boiling without constant monitoring. Induction heating blenders with integrated sensors offer rapid heating and automatic shut-off features, optimizing energy use and enhancing safety during boiling processes.

Layered Material Stockpot Bases

Layered material stockpot bases, often composed of aluminum and stainless steel, provide superior heat distribution and retention compared to induction heating blenders, ensuring even boiling without hotspots. This construction enhances energy efficiency and maintains consistent temperatures, making stockpots ideal for prolonged boiling tasks.

Enzyme-Preserving Heat Curve

Stockpots provide consistent, gradual heating that closely follows an enzyme-preserving heat curve ideal for boiling delicate ingredients, maintaining nutritional integrity. In contrast, induction heating blenders deliver rapid, uneven heat spikes that can degrade enzymes, potentially diminishing the health benefits of boiled foods.

Auto-Lift Boil Basket

The Auto-Lift Boil Basket in stockpots provides precise control over boiling by allowing easy immersion and removal of ingredients without compromising safety or temperature stability. Induction heating blenders offer rapid, energy-efficient boiling but often lack the specialized boil basket feature, making stockpots with Auto-Lift Boil Baskets ideal for tasks requiring consistent and controlled boiling.

Stockpot vs Induction heating blender for boiling. Infographic

cookingdiff.com

cookingdiff.com