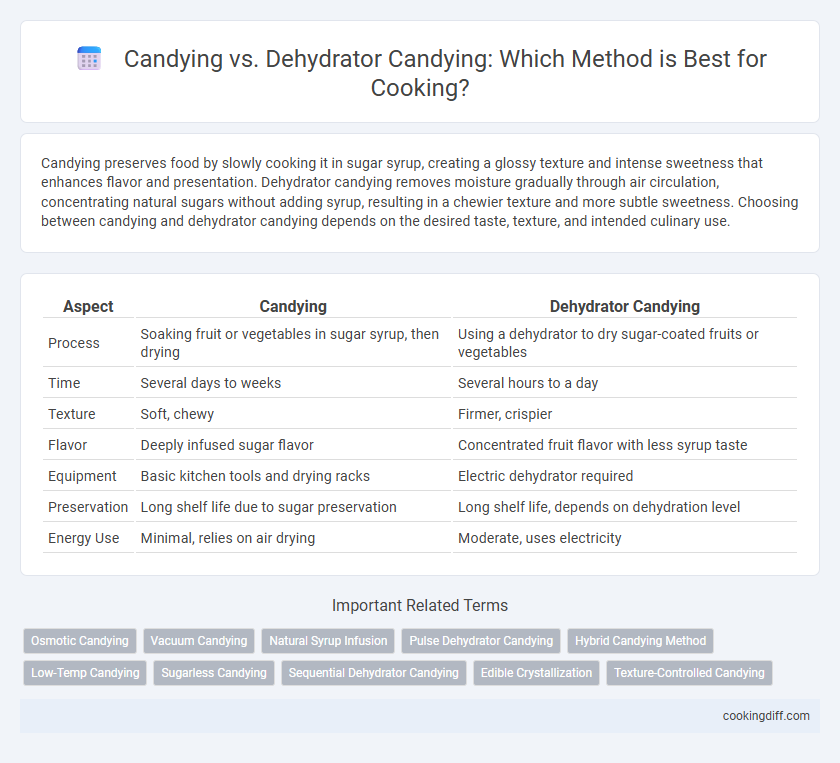

Candying preserves food by slowly cooking it in sugar syrup, creating a glossy texture and intense sweetness that enhances flavor and presentation. Dehydrator candying removes moisture gradually through air circulation, concentrating natural sugars without adding syrup, resulting in a chewier texture and more subtle sweetness. Choosing between candying and dehydrator candying depends on the desired taste, texture, and intended culinary use.

Table of Comparison

| Aspect | Candying | Dehydrator Candying |

|---|---|---|

| Process | Soaking fruit or vegetables in sugar syrup, then drying | Using a dehydrator to dry sugar-coated fruits or vegetables |

| Time | Several days to weeks | Several hours to a day |

| Texture | Soft, chewy | Firmer, crispier |

| Flavor | Deeply infused sugar flavor | Concentrated fruit flavor with less syrup taste |

| Equipment | Basic kitchen tools and drying racks | Electric dehydrator required |

| Preservation | Long shelf life due to sugar preservation | Long shelf life, depends on dehydration level |

| Energy Use | Minimal, relies on air drying | Moderate, uses electricity |

Introduction to Candying and Dehydrator Candying

Candying is a traditional cooking method that involves soaking fruits in sugar syrup to preserve and sweeten them, enhancing flavor and texture. Dehydrator candying, on the other hand, utilizes controlled low heat to remove moisture while infusing sweetness without boiling.

- Candying Technique - Involves simmering fruits in sugar syrup to achieve preservation and sweetness through sugar infusion.

- Dehydrator Candying - Uses low-temperature airflow to dry fruits gradually while coating them with sugar for a chewy texture.

- Flavor and Texture - Candying results in soft, translucent fruits, whereas dehydrator candying produces slightly firmer, more textured pieces.

Both methods preserve fruits but differ significantly in process and final texture, catering to diverse culinary preferences.

History and Origins of Traditional Candying

Traditional candying dates back to ancient civilizations, where sugar preservation methods were developed to extend the shelf life of fruits and vegetables. Early examples of candying can be traced to medieval Europe and the Middle East, where the technique was prized for both culinary and medicinal purposes.

The use of a dehydrator for candying is a modern adaptation that allows for more controlled moisture removal and consistent texture. While traditional candying relies on simmering and slow drying, dehydrators offer a convenient alternative that enhances efficiency without sacrificing flavor.

Overview of the Dehydrator Candying Process

The dehydrator candying process involves slowly drying fruits or vegetables at low temperatures to preserve natural flavors and sugars while achieving a chewy texture. Unlike traditional candying, this method reduces moisture content without submerging the produce in sugary syrup, resulting in a healthier and less sticky treat. Dehydrators offer precise temperature control, improving consistency and extending shelf life for homemade candied products.

Key Differences Between Traditional and Dehydrator Candying

Candying preserves fruits by soaking them in sugar syrup, creating a sweet, glossy coating, while dehydrator candying removes moisture through heat circulation, intensifying natural flavors and firmness. The two methods differ significantly in texture, time required, and moisture retention.

- Texture Variation - Traditional candying results in a soft, syrup-infused texture, whereas dehydrator candying produces a chewier, drier product.

- Processing Time - Candying typically requires several hours to days for syrup absorption, while dehydrator candying is faster, often completed within hours.

- Moisture Retention - Traditional candying maintains higher moisture content, contrasting with dehydration's focus on removing water to extend shelf life.

Flavor and Texture Comparison

How does candying compare to dehydrator candying in terms of flavor and texture? Traditional candying infuses fruits with a rich, syrupy sweetness that enhances flavor complexity and results in a tender, chewy texture. Dehydrator candying, by removing moisture more efficiently, produces a concentrated flavor with a firmer, drier bite ideal for snacking or baking.

Nutritional Impact: Candying vs Dehydrator Candying

Candying fruits often involves soaking them in sugar syrup, which increases their calorie and sugar content significantly, impacting the nutritional value by adding empty calories. Dehydrator candying, on the other hand, removes water without adding sugar, preserving more of the fruit's natural nutrients and fiber while reducing sugar intake.

While traditional candying can lead to higher glycemic index foods, dehydrator candying maintains lower sugar levels and enhances vitamin retention, particularly vitamin C and antioxidants. Choosing dehydrator candying supports healthier snacking options by minimizing added sugars and maintaining more of the fruit's original nutrition.

Best Foods for Each Candying Method

| Method | Best Foods | Key Advantages |

|---|---|---|

| Candying | Citrus peels, ginger, cherries, pineapple | Preserves moisture and intensifies natural sweetness through sugar infusion. |

| Dehydrator Candying | Apples, bananas, mangoes, berries | Enhances shelf life and concentrates flavors by removing moisture more evenly. |

Equipment and Tools Needed

Candying requires stovetop equipment such as a heavy-bottomed saucepan to simmer sugar syrup and a slotted spoon for handling delicate fruit pieces. Dehydrator candying involves a food dehydrator to gently remove moisture over time, preserving texture without cooking in liquid.

- Stovetop saucepan - Essential for boiling sugar and fruit syrup in traditional candying.

- Slotted spoon - Used for lifting candied items from syrup while minimizing breakage.

- Food dehydrator - Provides controlled, low-temperature drying ideal for slow moisture removal in dehydrator candying.

Step-by-Step Guide: Traditional vs Dehydrator Candying

Traditional candying involves simmering fruit in a sugar syrup until it becomes translucent and infused with sweetness, requiring careful temperature control and gradual syrup thickening. Dehydrator candying uses a low-temperature dehydrator to slowly remove moisture from sugar-coated fruit, preserving flavor and texture with less active monitoring. Both methods necessitate precise timing and preparation, but dehydrator candying offers a more consistent drying process ideal for uniform batches.

Related Important Terms

Osmotic Candying

Osmotic candying uses a sugar solution to preserve and sweeten fruits by drawing out moisture without high heat, maintaining texture and flavor better than dehydrator candying, which relies on drying to remove moisture but can alter the fruit's natural taste. This process enhances shelf life and intensifies sweetness through controlled osmotic pressure, making it ideal for delicate fruits prone to damage in dehydrators.

Vacuum Candying

Vacuum candying enhances flavor infusion and reduces cooking time by extracting air and moisture under low pressure, preserving the fruit's natural texture and color more effectively than traditional dehydrator candying. Unlike dehydrator candying, which relies on slow moisture removal through heat, vacuum candying maintains higher nutrient retention and produces a tender, evenly candied product.

Natural Syrup Infusion

Candying preserves fruits by slowly infusing natural syrup, enhancing flavor and texture through a precise sugar absorption process. Dehydrator candying relies on controlled low heat to remove moisture, but lacks the rich natural syrup infusion that deepens taste and appearance.

Pulse Dehydrator Candying

Pulse dehydrator candying uses rapid bursts of hot air to efficiently remove moisture from fruit, preserving flavor and texture better than traditional candying methods. This technique accelerates dehydration while minimizing sugar absorption, resulting in a higher-quality, sweetened product with enhanced shelf life and nutritional retention.

Hybrid Candying Method

The hybrid candying method combines the meticulous sugar infusion of traditional candying with the efficient moisture removal of dehydration, resulting in fruit with enhanced flavor concentration and extended shelf life. This technique leverages controlled temperature and humidity settings to preserve texture while maximizing sugar penetration, outperforming standard dehydrator candying in sweetness and chewiness.

Low-Temp Candying

Low-temp candying preserves the natural texture and flavor of fruits by slowly infusing them with sugar syrup without reaching high temperatures that cause caramelization or hardness. Unlike dehydrator candying, which relies on consistent airflow and heat to remove moisture, low-temp candying maintains moisture balance, resulting in tender, flavorful candied fruits ideal for delicate culinary applications.

Sugarless Candying

Sugarless candying preserves natural fruit flavors and nutrients by using alternative sweeteners like erythritol or stevia, avoiding traditional sugar's high caloric content. Dehydrator candying enhances texture and shelf-life through controlled low heat, but sugarless methods require careful monitoring to prevent texture degradation or microbial growth.

Sequential Dehydrator Candying

Sequential dehydrator candying enhances traditional candying by gradually removing moisture through controlled heat and airflow, preserving flavor and texture more efficiently. This method optimizes sugar infusion and ensures even dehydration, resulting in consistent, high-quality candied fruits compared to conventional candying techniques.

Edible Crystallization

Candying creates edible crystallization by slowly infusing sugar syrup into fruit, resulting in a glossy, tender texture. Dehydrator candying relies on low heat and extended drying to evaporate moisture, promoting natural sugar crystallization while preserving flavor and structure.

Candying vs Dehydrator Candying for cooking. Infographic

cookingdiff.com

cookingdiff.com