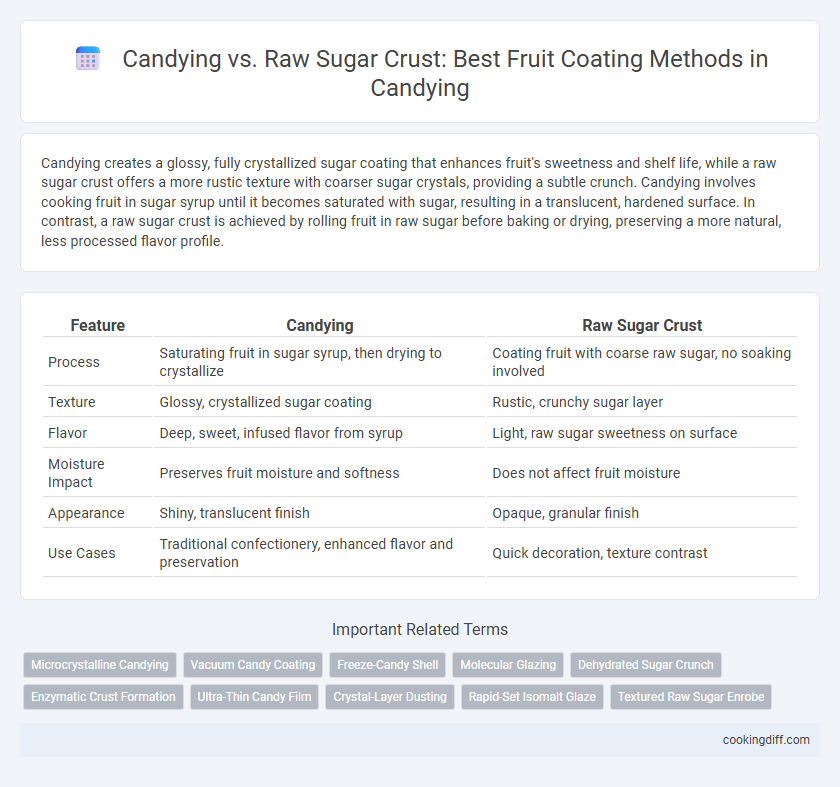

Candying creates a glossy, fully crystallized sugar coating that enhances fruit's sweetness and shelf life, while a raw sugar crust offers a more rustic texture with coarser sugar crystals, providing a subtle crunch. Candying involves cooking fruit in sugar syrup until it becomes saturated with sugar, resulting in a translucent, hardened surface. In contrast, a raw sugar crust is achieved by rolling fruit in raw sugar before baking or drying, preserving a more natural, less processed flavor profile.

Table of Comparison

| Feature | Candying | Raw Sugar Crust |

|---|---|---|

| Process | Saturating fruit in sugar syrup, then drying to crystallize | Coating fruit with coarse raw sugar, no soaking involved |

| Texture | Glossy, crystallized sugar coating | Rustic, crunchy sugar layer |

| Flavor | Deep, sweet, infused flavor from syrup | Light, raw sugar sweetness on surface |

| Moisture Impact | Preserves fruit moisture and softness | Does not affect fruit moisture |

| Appearance | Shiny, translucent finish | Opaque, granular finish |

| Use Cases | Traditional confectionery, enhanced flavor and preservation | Quick decoration, texture contrast |

Introduction to Fruit Coatings

Fruit coatings enhance the texture and flavor of fresh and preserved fruits, offering protection and improved shelf life. Candying involves saturating fruit with sugar syrup, creating a sweet, glossy layer that intensifies flavor and provides a chewy texture.

Raw sugar crust fruit coatings form a coarse, crunchy shell using unrefined sugar crystals, contrasting with the smooth, transparent finish of candying. These coatings act as natural preservatives by reducing moisture loss and inhibiting microbial growth. Both methods are essential in artisanal confectionery for balancing sweetness and texture while showcasing the fruit's natural qualities.

What is Candying?

Candying is a preservation method that involves soaking fruit in sugar syrup until it becomes saturated with sugar, creating a sweet, translucent coating. This process not only extends the fruit's shelf life but also enhances its flavor and texture by replacing water content with sugar. Unlike a raw sugar crust, which simply coats the fruit's exterior, candying penetrates the fruit, ensuring a uniform and long-lasting sweetness.

Understanding Raw Sugar Crust

Raw sugar crust acts as a protective barrier on fruit, preserving moisture and enhancing texture without significantly altering the fruit's natural flavor. This crust forms when raw sugar crystals absorb fruit juices and harden during the drying process, creating a rustic, crunchy coating.

Unlike candying, which involves soaking fruit in sugar syrup to infuse sweetness thoroughly, raw sugar crust relies on the granulated sugar's physical properties for preservation. Understanding this distinction helps in achieving desired texture and appearance in fruit coatings for culinary applications.

Key Differences: Candying vs Raw Sugar Crust

What are the key differences between candying and a raw sugar crust for fruit coatings? Candying involves immersing fruit in a sugar syrup to create a translucent, flavorful glaze, while raw sugar crust coats fruit with coarse sugar crystals for a crunchy texture. Candying preserves the fruit's moisture, whereas raw sugar crust adds a contrasting exterior crunch without altering the internal texture.

Flavor Profiles: Candying vs Raw Sugar Crust

Candying fruit infuses it with a rich, concentrated sweetness and complex caramelized notes, enhancing its natural flavors through slow cooking in sugar syrup. Raw sugar crust creates a textured, crunchy exterior with a more straightforward, molasses-like sweetness that contrasts with the fruit's juiciness. Flavor profiles differ as candying deepens aromatic qualities, while raw sugar crust offers an intense, rustic sweetness and tactile contrast.

Texture and Mouthfeel Comparison

Candying fruit creates a smooth, glossy coating that offers a soft and chewy texture, enhancing the overall mouthfeel. Raw sugar crust, by contrast, provides a coarse, crunchy exterior that adds a contrasting crisp bite to the fruit.

- Candying texture - Produces a tender, pliable surface that melds with the fruit's natural softness.

- Raw sugar crust texture - Forms a granular, firm layer that introduces a crunchy sensation.

- Mouthfeel impact - Candying yields a cohesive chewiness, while raw sugar crust enhances contrast through crispness.

The choice between candying and raw sugar crust depends on the desired sensory experience and textural preference for fruit coatings.

Shelf Life and Preservation Effects

Candying preserves fruit by infusing it with sugar, significantly extending shelf life through moisture removal and microbial inhibition. Raw sugar crust offers a protective barrier but provides comparatively less preservation and a shorter shelf life.

- Candying extends shelf life - High sugar concentration reduces water activity, preventing microbial growth and spoilage.

- Raw sugar crust offers limited preservation - Acts as a moisture barrier but does not deeply penetrate the fruit to inhibit microbes effectively.

- Candying enhances storage stability - The crystallized sugar matrix preserves texture and flavor longer than raw sugar coatings.

Best Fruits for Candying and Sugar Crust

Candying fruit involves simmering it in sugar syrup to create a translucent, sweet coating that preserves texture and enhances flavor, making citrus peel, cherries, and ginger ideal candidates due to their firm structure. Raw sugar crust, which uses coarse raw sugar crystals for a crunchy exterior, works best with fruits like pears, apples, and strawberries that hold shape well under less invasive coating methods.

Fruits with high water content like watermelon or berries with delicate skins are less suitable for candying or sugar crust as they can become soggy or lose form. Choosing fruits with a balance of firmness and natural sweetness ensures optimal results when applying either candying or raw sugar crust techniques for delicious, aesthetically pleasing treats.

Culinary Applications and Presentation

| Culinary Applications | Candied fruit offers a glossy, flavorful coating ideal for pastries and confections, enhancing sweetness and texture. Raw sugar crust provides a crunchy exterior that adds a rustic appeal to baked goods and fruit toppings. Both methods preserve fruit but differ in sweetness intensity and texture, influencing recipe outcomes. |

| Presentation | Candied fruit creates vibrant, translucent surfaces that highlight natural colors and add eye-catching shine. Raw sugar crusts produce a coarse, crystalline finish offering a handcrafted, artisanal look. Visual contrast between smooth candying and coarse sugar crust elevates the aesthetic appeal of desserts and fruit displays. |

Related Important Terms

Microcrystalline Candying

Microcrystalline candying creates a fine, stable sugar crust on fruit surfaces, offering enhanced preservation and a smoother texture compared to raw sugar crusts, which tend to be coarser and less uniform. The microcrystalline structure promotes better moisture retention and prevents crystallization issues common with raw sugar coatings.

Vacuum Candy Coating

Vacuum candy coating ensures superior penetration and preservation of fruit texture compared to raw sugar crust, offering enhanced flavor retention and extended shelf life. This method reduces crystallization and moisture loss, resulting in a smoother, more uniform fruit coating ideal for high-quality confectionery products.

Freeze-Candy Shell

Freeze-candy shell forms an ultra-thin, crisp coating that preserves fruit texture and flavor better than traditional candying or raw sugar crust methods. This coating technique uses rapid freezing combined with a sugar glaze to provide a glossy, crack-resistant surface that extends shelf life without the heavy, granular residue of raw sugar crust.

Molecular Glazing

Candying involves molecular glazing that creates a protective, sweet crystalline layer on fruit surfaces, enhancing preservation and flavor intensity; raw sugar crusts provide a rustic coating but lack the uniform molecular structure and glass-like finish of candying techniques. Molecular glazing in candying chemically binds sugar molecules, forming a durable, transparent shield that maintains texture and inhibits moisture loss more effectively than coarse sugar coatings.

Dehydrated Sugar Crunch

Dehydrated sugar crunch offers a crisp, textured alternative to raw sugar crust in fruit coatings, enhancing both flavor retention and shelf life through effective moisture removal. Unlike raw sugar crust, candying with dehydrated sugar crunch creates a uniform, glossy finish that prevents fruit spoilage and maintains sweetness without adding excessive stickiness.

Enzymatic Crust Formation

Candying involves enzymatic crust formation, where natural enzymes in fruit interact with sugar to create a translucent, flavorful coating that enhances texture and preserves freshness. Unlike raw sugar crust, which is simply a crystalline sugar layer, enzymatic crust improves moisture retention and offers a superior balance of sweetness and fruit integrity.

Ultra-Thin Candy Film

Ultra-thin candy film in candying creates a delicate, glossy coating that enhances fruit appearance and flavor without the thick, grainy texture often found in raw sugar crusts. This refined layer preserves fruit moisture while providing a crisp bite, offering superior translucency and a smoother mouthfeel compared to traditional raw sugar coatings.

Crystal-Layer Dusting

Candying creates a glossy, thick crystal-layer dusting on fruit coatings, enhancing texture and visual appeal compared to raw sugar crust, which results in a coarser, less uniform surface. The crystalline structure in candying forms a durable, clear glaze that preserves fruit moisture, while raw sugar crust tends to absorb moisture and lose its sparkle over time.

Rapid-Set Isomalt Glaze

Rapid-Set Isomalt Glaze offers a crystal-clear, smooth coating ideal for candying fruit, creating a durable, non-sticky shell that contrasts with the coarse texture of raw sugar crusts. Unlike raw sugar, which can absorb moisture and soften over time, Isomalt glaze provides long-lasting shine and preserves fruit integrity.

Candying vs Raw Sugar Crust for fruit coatings. Infographic

cookingdiff.com

cookingdiff.com