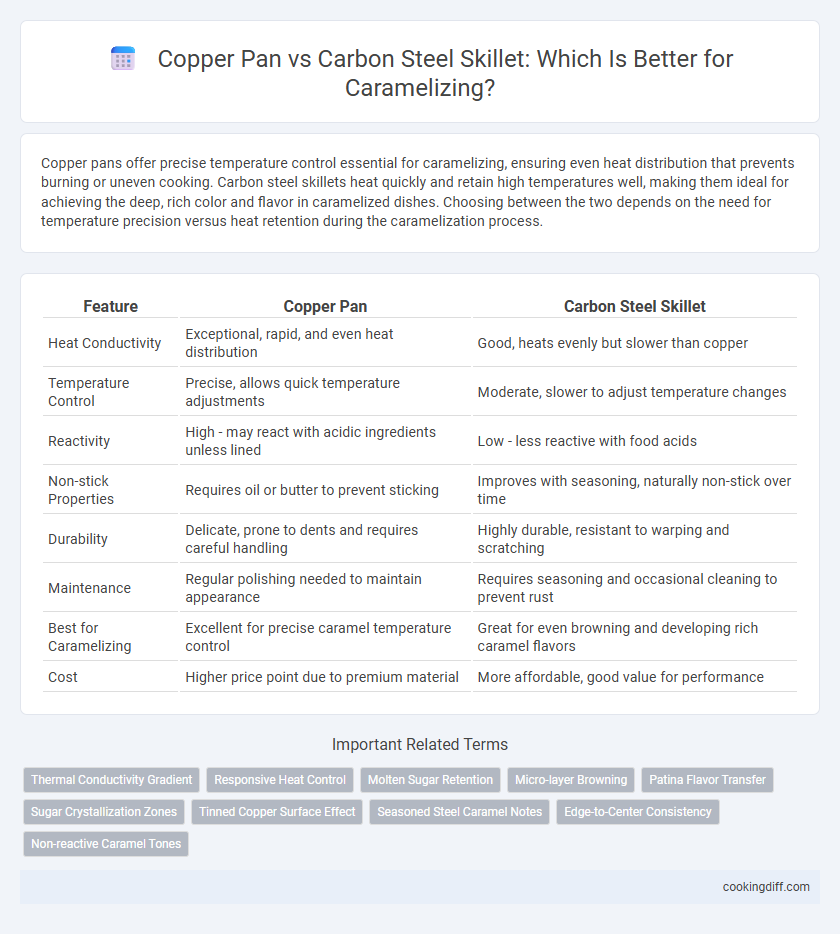

Copper pans offer precise temperature control essential for caramelizing, ensuring even heat distribution that prevents burning or uneven cooking. Carbon steel skillets heat quickly and retain high temperatures well, making them ideal for achieving the deep, rich color and flavor in caramelized dishes. Choosing between the two depends on the need for temperature precision versus heat retention during the caramelization process.

Table of Comparison

| Feature | Copper Pan | Carbon Steel Skillet |

|---|---|---|

| Heat Conductivity | Exceptional, rapid, and even heat distribution | Good, heats evenly but slower than copper |

| Temperature Control | Precise, allows quick temperature adjustments | Moderate, slower to adjust temperature changes |

| Reactivity | High - may react with acidic ingredients unless lined | Low - less reactive with food acids |

| Non-stick Properties | Requires oil or butter to prevent sticking | Improves with seasoning, naturally non-stick over time |

| Durability | Delicate, prone to dents and requires careful handling | Highly durable, resistant to warping and scratching |

| Maintenance | Regular polishing needed to maintain appearance | Requires seasoning and occasional cleaning to prevent rust |

| Best for Caramelizing | Excellent for precise caramel temperature control | Great for even browning and developing rich caramel flavors |

| Cost | Higher price point due to premium material | More affordable, good value for performance |

Introduction: The Science of Caramelization

Caramelization is the chemical process where sugars break down and develop rich flavors and brown hues at high temperatures. The choice between copper pans and carbon steel skillets affects heat conduction and temperature control essential for perfect caramelization.

- Copper Pan - Offers superior heat conductivity enabling precise temperature adjustments crucial for controlled caramelization.

- Carbon Steel Skillet - Provides excellent heat retention which helps maintain steady temperatures during the caramelization process.

- Temperature Sensitivity - Caramelization requires consistent heat between 320degF and 350degF to prevent burning or undercooking sugars.

Selecting the right pan balances heat responsiveness and retention to optimize caramelization outcomes.

Key Factors in Caramelizing: Heat Control and Reactivity

Copper pans offer superior heat control due to their excellent thermal conductivity, allowing precise temperature adjustments crucial for caramelizing sugar evenly without burning. Carbon steel skillets heat quickly and retain heat well but are more reactive, which can affect the flavor and color of delicate caramel. Choosing between copper and carbon steel depends on prioritizing consistent temperature management or a more robust, dynamic cooking surface.

Copper Pan Overview: Properties and Advantages

Copper pans offer exceptional thermal conductivity, allowing precise temperature control essential for perfect caramelization. Their rapid heat response helps prevent burning, making them ideal for delicate sugar work compared to carbon steel skillets.

- Superior Heat Conductivity - Copper distributes heat evenly and instantly, reducing hot spots during caramelization.

- Precise Temperature Control - Quick response to temperature changes enables better management of sugar's delicate caramelizing stages.

- Durability with Proper Care - Although reactive, copper pans last long when lined appropriately, preserving quality and performance.

Carbon Steel Skillet Overview: Features and Benefits

Carbon steel skillets heat quickly and evenly, providing precise temperature control essential for perfect caramelization. Their natural non-stick surface develops with seasoning, preventing sugar from sticking and burning during the process.

Compared to copper pans, carbon steel offers superior heat retention and durability, making it ideal for repeated caramelizing tasks. Its lightweight nature and versatility also allow seamless transition from stovetop to oven for recipes requiring varied cooking techniques.

Heat Conductivity: Copper vs Carbon Steel for Even Browning

| Material | Heat Conductivity | Effect on Caramelizing |

| Copper Pan | Highest thermal conductivity (approx. 401 W/mK) | Allows rapid, even browning by quickly distributing heat, minimizing hot spots and preventing sugar from burning during caramelization. |

| Carbon Steel Skillet | Moderate thermal conductivity (approx. 54 W/mK) | Heats more gradually and less evenly than copper, which may cause uneven caramelization and requires careful heat management for even browning. |

Reactivity with Sugars and Food Acids

Copper pans offer superior heat conductivity and precise temperature control, minimizing hot spots that can burn sugars during caramelization. Their low reactivity with food acids preserves the pure flavor of caramel without imparting metallic tastes.

Carbon steel skillets, while also providing good heat retention, react slightly more with acidic ingredients, which can influence the caramel's flavor and color. This reactivity may cause uneven caramelization and requires careful seasoning to maintain a non-stick surface and reduce off-flavors.

Durability and Ease of Maintenance

Copper pans offer superior heat conductivity, making them ideal for precise caramelizing but require regular polishing to maintain their appearance and prevent tarnish. Carbon steel skillets are highly durable, developing a natural non-stick patina over time that simplifies maintenance and enhances caramelization.

The durability of carbon steel makes it resistant to warping and chipping, which is beneficial for frequent caramelizing tasks. Copper pans, though less durable, provide unmatched temperature control crucial for achieving the perfect caramel consistency. Both materials require specific care, with carbon steel needing seasoning and copper demanding gentle cleaning to preserve functionality and longevity.

User Experience: Handling and Weight

Copper pans offer superior heat conductivity and precise temperature control, enhancing the caramelizing process but tend to be heavier, which may affect user comfort during extended cooking. Carbon steel skillets are lighter and develop a natural non-stick patina over time, making them easier to handle and ideal for frequent use. The choice between these materials depends on balancing the need for temperature responsiveness with ease of maneuverability in the kitchen.

Price Comparison and Value for Money

Which offers better value for money when caramelizing, a copper pan or a carbon steel skillet? Copper pans typically come with a higher price tag due to superior heat conductivity, providing precise temperature control essential for perfect caramelization. Carbon steel skillets offer a more affordable option with good heat retention, making them a cost-effective choice for home cooks seeking reliable performance.

Related Important Terms

Thermal Conductivity Gradient

Copper pans exhibit superior thermal conductivity, enabling rapid and even heat distribution essential for precise caramelizing, while carbon steel skillets have a lower thermal conductivity gradient that may cause uneven heating and increased risk of scorching. The high thermal conductivity of copper allows for better temperature control and consistent caramelization results compared to carbon steel.

Responsive Heat Control

Copper pans provide superior responsive heat control during caramelizing due to their excellent thermal conductivity, allowing precise temperature adjustments that prevent sugar from burning. Carbon steel skillets heat quickly but retain heat longer, which can lead to uneven caramelization and requires more careful temperature management.

Molten Sugar Retention

Copper pans provide superior thermal conductivity, enabling precise temperature control that prevents sugar from burning during caramelization, while their smooth surface promotes even molten sugar retention. Carbon steel skillets, though durable and responsive, tend to develop seasoning layers that may cause uneven caramel adhesion and less consistent molten sugar retention compared to copper.

Micro-layer Browning

Copper pans offer superior thermal conductivity, allowing precise temperature control essential for even micro-layer browning during caramelizing, while carbon steel skillets provide excellent heat retention that helps maintain consistent browning without hot spots. The choice between copper and carbon steel affects the caramelization's depth and uniformity, with copper enabling quicker adjustments and carbon steel delivering sustained heat for gradual, controlled micro-layer browning.

Patina Flavor Transfer

Carbon steel skillets develop a natural patina that enhances flavor transfer during caramelizing, creating a richer, more complex taste profile as the seasoned surface interacts with sugars. Copper pans, while excellent for precise temperature control, lack this seasoning buildup, resulting in less flavor infusion compared to the evolving patina of carbon steel.

Sugar Crystallization Zones

Copper pans offer superior temperature control for caramelizing sugar, minimizing sugar crystallization zones due to their rapid heat conductivity and even heat distribution. In contrast, carbon steel skillets can develop hot spots that increase the risk of uneven caramelization and unwanted sugar crystallization, making copper the preferred choice for precision caramel work.

Tinned Copper Surface Effect

Tinned copper pans offer exceptional thermal conductivity for precise temperature control during caramelizing, preventing hotspots that can cause uneven browning. The tin coating provides a non-reactive surface that protects the copper from acidity in caramelizing sugars, ensuring a pure, clean flavor and easy cleanup.

Seasoned Steel Caramel Notes

A seasoned carbon steel skillet offers superior heat retention and an even sear crucial for developing deep caramelized notes without burning, thanks to its natural non-stick patina that intensifies flavors over time. Copper pans provide precise temperature control but lack the seasoning layer that enhances caramel complexity, making carbon steel the preferred choice for rich, nuanced caramelization.

Edge-to-Center Consistency

Copper pans provide superior edge-to-center heat consistency for caramelizing due to their exceptional thermal conductivity, allowing precise temperature control and uniform browning. Carbon steel skillets, while excellent at heat retention, often develop hot spots, resulting in uneven caramelization, especially towards the edges.

Copper Pan vs Carbon Steel Skillet for caramelizing. Infographic

cookingdiff.com

cookingdiff.com