Metal whisks provide superior heat resistance and durability when caramelizing, allowing for efficient stirring without melting or warping. Flat coil whisks excel in scraping the bottom of the pan, preventing caramel from burning by ensuring even heat distribution. Choosing between them depends on the caramelizing method: metal whisks offer robust control, while flat coil whisks enhance thorough mixing and prevent scorching.

Table of Comparison

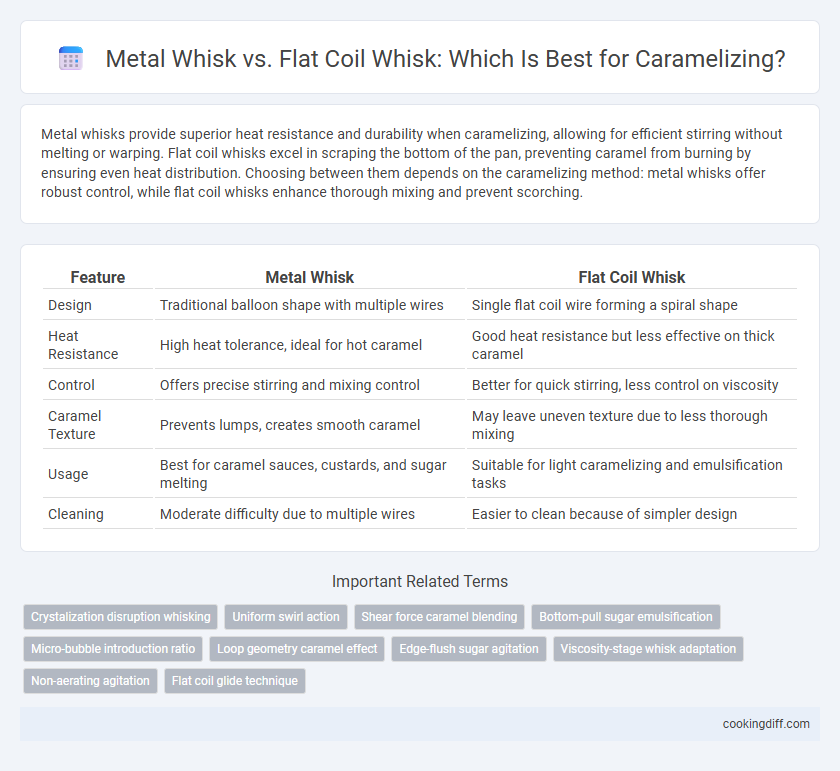

| Feature | Metal Whisk | Flat Coil Whisk |

|---|---|---|

| Design | Traditional balloon shape with multiple wires | Single flat coil wire forming a spiral shape |

| Heat Resistance | High heat tolerance, ideal for hot caramel | Good heat resistance but less effective on thick caramel |

| Control | Offers precise stirring and mixing control | Better for quick stirring, less control on viscosity |

| Caramel Texture | Prevents lumps, creates smooth caramel | May leave uneven texture due to less thorough mixing |

| Usage | Best for caramel sauces, custards, and sugar melting | Suitable for light caramelizing and emulsification tasks |

| Cleaning | Moderate difficulty due to multiple wires | Easier to clean because of simpler design |

Introduction to Whisks for Caramelizing

Choosing the right whisk is essential for effective caramelizing of sugar. Metal whisks and flat coil whisks offer distinct advantages in heat conduction and stirring efficiency.

- Metal Whisk - Provides excellent heat conduction, allowing quicker and more even caramelization.

- Flat Coil Whisk - Features a design that scrapes the pan's surface, preventing sugar from sticking and burning.

- Durability - Both types are made from stainless steel, ensuring resistance to high temperatures and long-lasting use.

Selecting between a metal whisk and a flat coil whisk depends on personal preference and caramelizing technique.

Understanding Caramelization: The Basics

Metal whisks, especially those with flat coil designs, offer superior control and heat distribution essential for precise caramelization. The flat coil whisk's increased surface area enhances the even mixing of sugars, preventing hot spots and ensuring smoother caramel development. Understanding these differences helps achieve the perfect caramel texture and color by allowing consistent stirring and temperature regulation during the caramelization process.

Metal Whisk Overview: Design and Function

| Metal Whisk Overview: Design and Function |

| The metal whisk, typically constructed from stainless steel, features a series of interconnected wires forming a balloon or flat coil shape designed for consistent stirring and aeration. Its rigid structure allows it to withstand high temperatures during caramelizing without warping or melting, making it ideal for preventing sugar crystallization. Unlike flat coil whisks, metal whisks provide efficient agitation by incorporating more surface area contact, ensuring uniform caramel formation and controlled heat distribution. |

Flat Coil Whisk Overview: Design and Function

The flat coil whisk features a distinctive design with tightly wound, flat metal coils that provide increased surface contact for efficient caramelizing. Its structure allows for rapid and even heat distribution, preventing sugar from crystallizing or burning during the caramelization process. This whisk's design ensures smooth stirring and superior control over the caramel's texture and consistency compared to a traditional metal whisk.

Mixing Efficiency: Metal vs Flat Coil Whisks

Metal whisks, with their rigid structure, provide superior mixing efficiency when caramelizing by evenly distributing heat and preventing sugar from burning. Their solid build allows for consistent stirring, essential for achieving the perfect caramel texture.

Flat coil whisks offer quicker incorporation of air and smoother mixing but may struggle with thicker caramel due to less surface contact and flexibility. These whisks are better suited for lighter blends, while metal whisks excel in managing the viscous nature of caramel during cooking.

Control and Precision During Caramelizing

Metal whisks provide superior control during caramelizing by distributing heat evenly, preventing scorching. Flat coil whisks offer precision in stirring, allowing for smooth, consistent caramel texture without over-agitating the mixture.

- Even Heat Distribution - Metal whisks conduct heat effectively, reducing hot spots in caramel.

- Precision Stirring - Flat coil whisks facilitate gentle, targeted mixing for uniform caramelization.

- Enhanced Control - Both whisks aid in steady temperature management, crucial for perfect caramel results.

Heat Resistance and Durability Comparison

Metal whisks generally offer superior heat resistance compared to flat coil whisks, making them more suitable for high-temperature caramelizing tasks. Their durability often surpasses that of flat coil whisks, which may deform or degrade under intense heat.

- Metal Whisk Heat Resistance - Metal whisks withstand higher temperatures without warping, ideal for caramelizing sugar at elevated heat levels.

- Flat Coil Whisk Heat Limitations - Flat coil whisks tend to have lower heat resistance, risking damage during prolonged exposure to caramelizing temperatures.

- Durability Comparison - Metal whisks generally maintain structural integrity longer, providing consistent performance in caramelizing processes.

Cleaning and Maintenance Considerations

Metal whisks, especially those with flat coils, tend to trap caramel in tight crevices, making cleaning more challenging. Flat coil whisks require thorough scrubbing to remove hardened caramel residues effectively.

Metal whisks are durable and withstand high temperatures during caramelizing, but their intricate designs can complicate maintenance. Flat coil whisks offer better control in caramel mixing but often demand soaking and meticulous cleaning to avoid buildup. Choosing a whisk with smooth, easily accessible wires reduces cleaning time and extends the tool's lifespan.

Recommended Uses: When to Choose Each Whisk

The metal whisk is ideal for caramelizing sauces and custards, as its sturdy construction allows efficient mixing without scratching non-stick surfaces. It excels in incorporating air into mixtures, helping to achieve smooth, even caramel textures.

The flat coil whisk is recommended for delicate caramel sauces where gentle stirring is required to prevent crystallization. Its design allows for scraping the sides of pans, ensuring even caramelization and preventing burning.

Related Important Terms

Crystalization disruption whisking

A metal whisk with thin, flexible wires is more effective at disrupting sugar crystallization during caramelizing, as it rapidly incorporates air and breaks up sugar clumps. Flat coil whisks, while sturdy, apply less precise agitation, making them less efficient for preventing grainy textures in caramel.

Uniform swirl action

A flat coil whisk provides a more uniform swirl action during caramelizing, ensuring even heat distribution and preventing hot spots that can cause burning. Metal whisks with balloon shapes may create inconsistent mixing, leading to uneven caramel textures and potential crystallization.

Shear force caramel blending

Metal whisks generate higher shear force during caramel blending compared to flat coil whisks, promoting faster sugar dissolution and uniform caramel texture. The rigid structure of metal whisks enables more effective agitation, reducing crystallization risks and enhancing caramelization consistency.

Bottom-pull sugar emulsification

Metal whisks with flat coils excel in bottom-pull sugar emulsification during caramelizing by efficiently reaching the pan's surface, ensuring uniform heat distribution and preventing crystallization. Their design agitates sugar at the base, promoting smooth caramel with consistent color and texture compared to standard balloon whisks.

Micro-bubble introduction ratio

Metal whisks introduce micro-bubbles at varying rates during caramelizing, with flat coil whisks generating a higher micro-bubble introduction ratio than standard metal whisks, enhancing even heat distribution and smoother caramel texture. The increased aeration from flat coil whisks reduces crystallization risk, promoting a consistent and glossy caramel finish.

Loop geometry caramel effect

The loop geometry of a metal whisk facilitates even heat distribution and efficient mixing during caramelizing, enhancing the smoothness and consistency of the caramel. In contrast, a flat coil whisk's design limits proper aeration and heat exposure, resulting in uneven caramel texture and potential crystal formation.

Edge-flush sugar agitation

A metal whisk with edge-flush wires ensures thorough sugar agitation during caramelizing, preventing uneven heating and crystallization. In contrast, a flat coil whisk might leave gaps that allow sugar to settle and overcook, compromising texture and consistency.

Viscosity-stage whisk adaptation

Metal whisks excel in caramelizing due to their durability and heat resistance, effectively managing high-viscosity mixtures without warping, while flat coil whisks offer superior surface contact for smoother incorporation of sugar crystals at the early stages. Choosing a whisk tailored to the viscosity stage of caramel, such as a metal whisk for thickened caramel and a flat coil for initial melting, ensures optimal texture and consistency.

Non-aerating agitation

A metal whisk with flat coils is ideal for caramelizing due to its efficient non-aerating agitation, allowing gentle stirring that prevents air incorporation and ensures smooth, even caramel formation. Unlike balloon whisks, the flat coil design minimizes splashing and facilitates precise control over sugar crystallization during the caramelization process.

Metal whisk vs flat coil whisk for caramelizing. Infographic

cookingdiff.com

cookingdiff.com