Classic oil filters rely on manual filtration through mesh screens or paper filters, which can be time-consuming and less efficient at removing fine particles from deep-frying oil. Gravity oil filtration systems use natural sedimentation, allowing heavier particles to settle at the bottom, resulting in clearer oil and extended usability without constant manual intervention. Choosing gravity filtration improves oil lifespan and frying quality by maintaining cleaner oil for prolonged cooking periods.

Table of Comparison

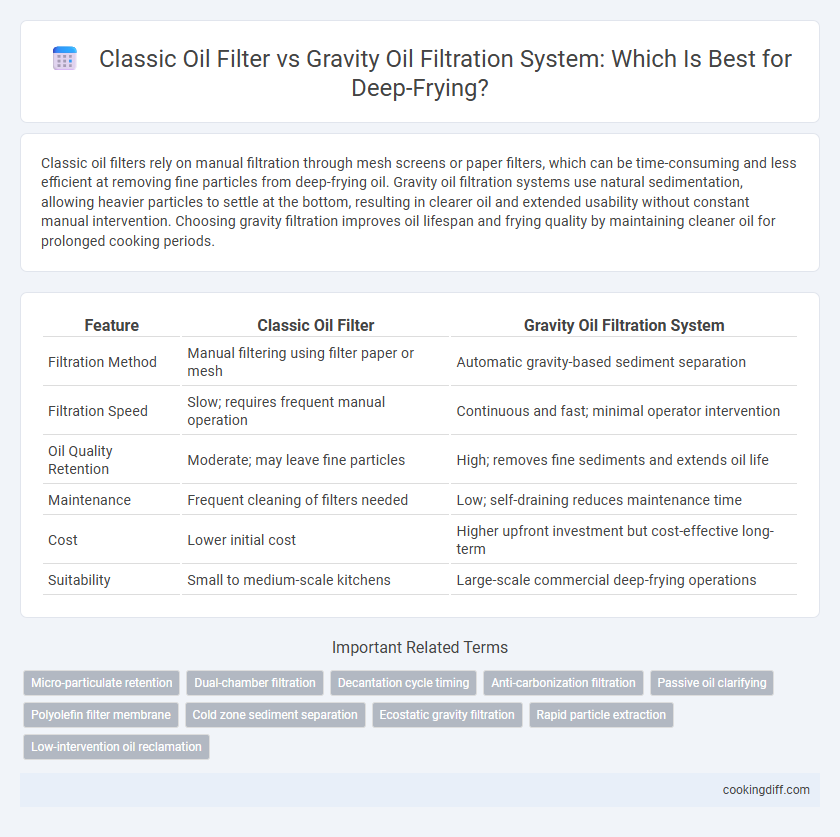

| Feature | Classic Oil Filter | Gravity Oil Filtration System |

|---|---|---|

| Filtration Method | Manual filtering using filter paper or mesh | Automatic gravity-based sediment separation |

| Filtration Speed | Slow; requires frequent manual operation | Continuous and fast; minimal operator intervention |

| Oil Quality Retention | Moderate; may leave fine particles | High; removes fine sediments and extends oil life |

| Maintenance | Frequent cleaning of filters needed | Low; self-draining reduces maintenance time |

| Cost | Lower initial cost | Higher upfront investment but cost-effective long-term |

| Suitability | Small to medium-scale kitchens | Large-scale commercial deep-frying operations |

Introduction to Oil Filtration in Deep-Frying

Oil filtration is essential in deep-frying to extend oil life and maintain food quality by removing particles and impurities. Two common methods include classic oil filters and gravity oil filtration systems, each with distinct mechanisms and efficiency levels.

Classic oil filters use mechanical means such as mesh screens and paper filters to trap debris, requiring manual operation and frequent cleaning. Gravity oil filtration systems rely on natural sedimentation and gravity to separate solid residues from the oil, offering a slower but low-maintenance approach. Selecting the appropriate filtration system depends on factors like frying volume, desired maintenance frequency, and oil quality goals.

Overview of Classic Oil Filters

Classic oil filters for deep-frying typically use a paper or mesh filter to remove food particles from hot oil, maintaining oil quality and extending its usable life. These filters require manual replacement or cleaning and are often integrated into fryer units for immediate filtration after cooking. While effective in removing larger debris, classic oil filters may not capture finer impurities, potentially affecting the oil's flavor and frying performance over time.

Understanding Gravity Oil Filtration Systems

How does a gravity oil filtration system improve oil quality in deep-frying compared to classic oil filters? Gravity oil filtration systems use natural sedimentation to separate food particles and impurities from cooking oil without requiring pumps or electricity. This method reduces oil degradation and extends its usability by filtering out fine debris more effectively than traditional mesh or paper filters.

Key Differences Between Classic and Gravity Filtration

Classic oil filters use mechanical pressure to push oil through fine mesh screens, effectively removing large particles but often missing finer impurities. Gravity oil filtration systems rely on natural sedimentation, allowing heavier food debris to settle before oil passes through filters, resulting in gentler oil treatment and extended oil life. The key difference lies in filtration method: classic systems apply force for quick filtering, while gravity systems emphasize slow, thorough purification, enhancing oil quality in deep-frying operations.

Filtration Efficiency and Oil Clarity

The gravity oil filtration system offers superior filtration efficiency by allowing particles to settle naturally, resulting in clearer oil compared to the classic oil filter. Classic oil filters tend to clog faster, reducing oil clarity and requiring more frequent replacements.

- Filtration Efficiency - Gravity systems use sedimentation to trap fine particles, enhancing oil longevity.

- Oil Clarity - Gravity filtration produces visibly clearer oil, improving food taste and appearance.

- Maintenance Frequency - Classic filters clog quickly, increasing downtime for cleaning and replacement.

Impact on Food Flavor and Quality

Classic oil filters often leave behind fine particles and food residues, which can negatively affect the flavor and quality of deep-fried foods. Gravity oil filtration systems provide a more thorough cleaning, preserving the oil's integrity and enhancing the taste and crispiness of fried items.

- Oil Purity Retention - Gravity filtration removes more impurities, maintaining oil clarity and reducing off-flavors.

- Flavor Consistency - Cleaner oil from gravity filtration prevents flavor transfer between batches.

- Food Texture Enhancement - Reduced residue leads to a crisper, more consistent texture in fried foods.

Cost Analysis: Classic vs Gravity Filtration

The initial investment for classic oil filters averages $1,200, while gravity oil filtration systems cost approximately $800, offering a more budget-friendly option for small to medium-sized operations. Classic filters incur higher maintenance expenses, around $300 annually, due to the need for regular cartridge replacements and mechanical upkeep.

Gravity filtration systems reduce operational costs by minimizing filter media usage, resulting in annual expenses near $150, thus extending oil life and decreasing waste disposal fees. Over a five-year period, businesses can save up to 40% with gravity systems compared to classic oil filter setups, making them a cost-effective choice for deep-frying processes.

Maintenance and Usability Comparison

Classic oil filters require frequent manual cleaning to maintain performance, increasing downtime during busy frying operations. Gravity oil filtration systems offer a more automated, gravity-driven process that reduces operator effort and extends filter life.

- Maintenance Frequency - Classic filters need daily cleaning, while gravity systems allow longer intervals between maintenance.

- User Effort - Classic filters demand hands-on involvement, whereas gravity systems minimize labor through passive filtration.

- Durability - Gravity filtration units typically have sturdier components designed for continuous use, improving reliability in commercial kitchens.

Choosing a gravity oil filtration system enhances operational efficiency by simplifying maintenance and boosting usability over traditional classic oil filters.

Energy Consumption and Environmental Impact

Classic oil filters for deep-frying typically consume more energy due to the need for repeated heating and pumping cycles, increasing overall utility costs. Gravity oil filtration systems operate passively using gravitational force, significantly reducing energy consumption by eliminating the use of electric pumps and motors.

From an environmental perspective, gravity filtration minimizes waste by extending oil life and reducing the frequency of disposal, lowering the environmental footprint. Conventional filters often produce more residual waste and require higher electricity usage, contributing to increased carbon emissions and resource depletion.

Related Important Terms

Micro-particulate retention

Classic oil filters rely on fine mesh screens to trap large food particles but often allow micro-particulates to remain suspended in the oil, leading to quicker degradation and off-flavors. Gravity oil filtration systems utilize sedimentation principles to more effectively capture micro-particulates, improving oil clarity and extending its usable lifespan in deep-frying applications.

Dual-chamber filtration

Dual-chamber filtration systems in deep-frying utilize a segmented design where one chamber holds used oil while the second filters out food particles, enhancing oil clarity and extending usability compared to classic oil filters that rely mainly on mesh screens. This approach reduces oil oxidation and improves flavor retention by effectively separating debris and impurities, making it ideal for high-volume or commercial frying operations.

Decantation cycle timing

The decantation cycle timing in a classic oil filter typically ranges from 30 to 60 minutes, allowing sediment to settle before filtration begins, whereas a gravity oil filtration system relies on a slower, continuous process that can take several hours for effective separation. Optimizing cycle timing in gravity filtration enhances oil clarity and longevity by minimizing residual particulate matter compared to the relatively faster but less thorough classic method.

Anti-carbonization filtration

Classic oil filters use fine mesh screens that physically trap food particles but often allow smaller carbonized residues to remain, reducing oil life and increasing carbon buildup. Gravity oil filtration systems employ sedimentation and fine filtration technology to effectively remove microscopic carbonized particles, enhancing oil clarity and extending frying oil usability by minimizing anti-carbonization buildup.

Passive oil clarifying

A gravity oil filtration system uses passive oil clarifying by allowing suspended particles to settle naturally over time, reducing the need for constant manual intervention common in classic oil filters. This method prolongs oil life by minimizing oxidation and maintaining oil quality without extensive mechanical filtration.

Polyolefin filter membrane

Polyolefin filter membranes in gravity oil filtration systems offer superior oil clarity and extended frying life compared to classic oil filters by effectively removing fine particulates and impurities. This advanced filtration improves oil quality, reduces turnover frequency, and enhances food taste and safety in deep-frying operations.

Cold zone sediment separation

Classic oil filters rely on manual filtering that often leaves fine particles in the oil's cold zone, reducing oil lifespan and frying quality. Gravity oil filtration systems enhance cold zone sediment separation by allowing heavier particles to settle naturally, resulting in cleaner oil and extended filter intervals in deep-frying operations.

Ecostatic gravity filtration

The Ecostatic gravity oil filtration system offers superior oil clarity and extends frying oil life by efficiently removing fine particles and food debris compared to classic oil filters that rely on manual or mechanical pressure. This gravity-driven method reduces labor costs, energy consumption, and minimizes oil waste, optimizing operational sustainability for deep-frying applications.

Rapid particle extraction

Classic oil filters rely on mesh screens or cartridges to trap particles, which can slow down the filtration process and reduce efficiency during deep-frying. Gravity oil filtration systems enable rapid particle extraction by allowing oil to flow naturally through finer filtration media, resulting in cleaner oil and extended frying life.

Classic oil filter vs gravity oil filtration system for deep-frying. Infographic

cookingdiff.com

cookingdiff.com