Deep-frying poultry results in a crispy exterior but can lead to uneven cooking and oil absorption, potentially making the meat less juicy. Pressure-frying uses high pressure to cook the poultry faster, sealing in moisture and producing a tender, flavorful interior with less oil penetration. This method enhances food safety by reaching higher internal temperatures more quickly, reducing the risk of undercooked meat.

Table of Comparison

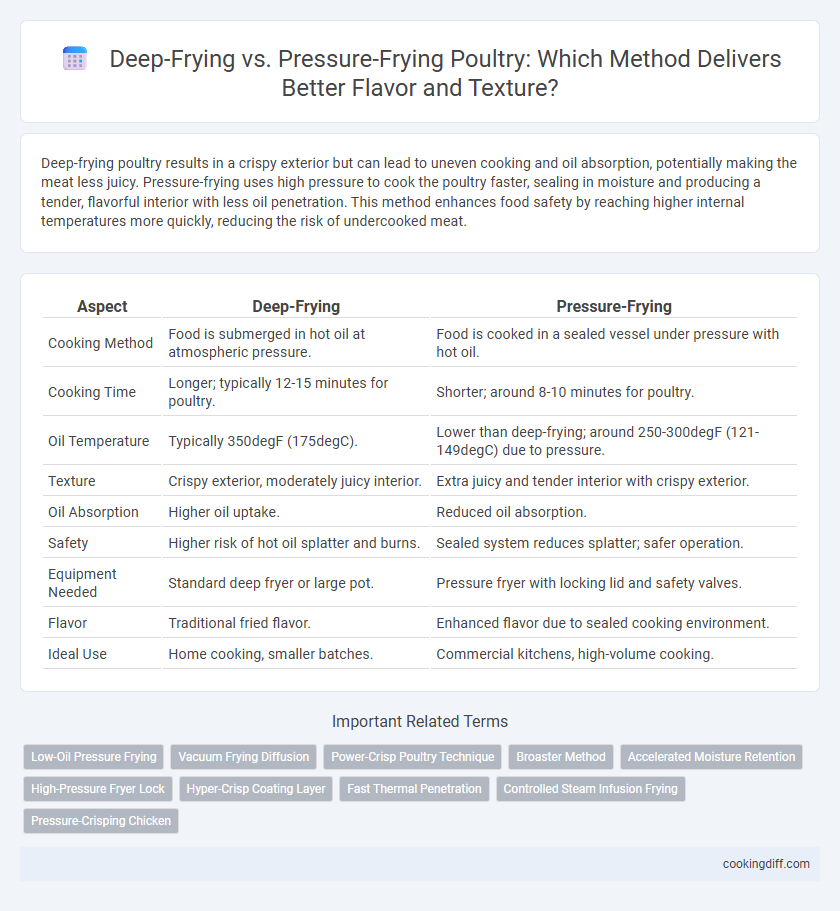

| Aspect | Deep-Frying | Pressure-Frying |

|---|---|---|

| Cooking Method | Food is submerged in hot oil at atmospheric pressure. | Food is cooked in a sealed vessel under pressure with hot oil. |

| Cooking Time | Longer; typically 12-15 minutes for poultry. | Shorter; around 8-10 minutes for poultry. |

| Oil Temperature | Typically 350degF (175degC). | Lower than deep-frying; around 250-300degF (121-149degC) due to pressure. |

| Texture | Crispy exterior, moderately juicy interior. | Extra juicy and tender interior with crispy exterior. |

| Oil Absorption | Higher oil uptake. | Reduced oil absorption. |

| Safety | Higher risk of hot oil splatter and burns. | Sealed system reduces splatter; safer operation. |

| Equipment Needed | Standard deep fryer or large pot. | Pressure fryer with locking lid and safety valves. |

| Flavor | Traditional fried flavor. | Enhanced flavor due to sealed cooking environment. |

| Ideal Use | Home cooking, smaller batches. | Commercial kitchens, high-volume cooking. |

Introduction to Poultry Frying Methods

What are the main differences between deep-frying and pressure-frying poultry? Deep-frying submerges poultry in hot oil at temperatures around 350-375degF, producing a crispy texture with a classic fried flavor. Pressure-frying uses a sealed vessel to cook poultry faster at slightly lower temperatures, resulting in juicier meat with a tender crust due to retained moisture and reduced oil absorption.

What is Deep-Frying Poultry?

Deep-frying poultry involves submerging the meat in hot oil at temperatures typically between 350degF and 375degF, resulting in a crispy exterior and juicy interior. This cooking method uses convection heat to rapidly cook the poultry, sealing in moisture and enhancing flavor through Maillard browning. Compared to pressure-frying, deep-frying does not use a sealed environment, which affects cooking time and texture but produces a distinct crunch and traditional fried taste.

What is Pressure-Frying Poultry?

| Cooking Method | Description |

|---|---|

| Pressure-Frying Poultry | A cooking technique that combines deep-frying with pressure cooking by frying poultry in a sealed pressure vessel. This method retains moisture, producing juicier and more tender meat compared to traditional deep-frying. Pressure-frying also reduces cooking time and enhances flavor infusion, making it a preferred choice for commercial poultry preparation. |

Key Differences Between Deep-Frying and Pressure-Frying

Deep-frying cooks poultry by submerging it in hot oil at temperatures around 350-375degF, creating a crispy exterior and juicy interior through rapid moisture evaporation. Pressure-frying combines frying with a sealed pressure cooker environment, raising the boiling point of water and allowing poultry to cook faster while retaining more moisture and flavor. Key differences include cooking time, with pressure-frying significantly reducing it, and texture, where pressure-fried poultry tends to be more tender and less greasy than traditional deep-fried poultry.

Cooking Time Comparison: Deep-Frying vs Pressure-Frying

Deep-frying poultry typically requires higher temperatures and longer cooking times, averaging 12 to 15 minutes at 350degF. Pressure-frying reduces cooking time by 25-30%, often completing in 8 to 10 minutes due to the pressurized environment.

Pressure-frying maintains moisture and tenderness by sealing in juices during the shorter cooking process. The elevated pressure raises the boiling point of water inside the meat, which accelerates cooking without over-drying. This method is commonly preferred in commercial kitchens for efficiency and consistent results.

Flavor and Texture: How Methods Affect Poultry

Deep-frying poultry produces a crispy, golden crust with a traditional fried flavor, while pressure-frying locks in moisture and intensifies juiciness. Texture differences are notable as deep-frying yields a lighter, crunchier bite, whereas pressure-frying results in tender, succulent meat with a slightly thicker crust.

- Flavor Enhancement - Pressure-frying intensifies natural poultry flavors by cooking under pressure, preserving juices and aromas.

- Texture Contrast - Deep-frying creates a crisp exterior due to higher cooking temperatures and exposed hot oil contact.

- Moisture Retention - Pressure-frying significantly reduces moisture loss, maintaining juiciness compared to traditional deep-frying.

Choosing between deep-frying and pressure-frying depends on desired flavor profiles and textural preferences for poultry dishes.

Oil Absorption and Health Considerations

Deep-frying typically results in higher oil absorption in poultry compared to pressure-frying, which uses steam pressure to reduce oil uptake and cooking time. Health considerations favor pressure-frying due to lower fat content and decreased formation of harmful compounds like acrylamide.

- Oil Absorption Differences - Deep-frying allows prolonged exposure to hot oil, increasing fat penetration into the poultry's surface and interior.

- Reduced Cooking Time - Pressure-frying cooks poultry faster by combining high pressure and steam, limiting oil absorption and preserving moisture.

- Health Benefits - Lower oil uptake in pressure-frying reduces caloric content and minimizes toxic byproducts, promoting a healthier meal.

Equipment Needed for Each Frying Method

Deep-frying poultry requires a standard deep fryer or a heavy-duty pot with a thermometer to maintain consistent oil temperature. Pressure-frying involves specialized pressure fryers that combine deep frying with sealed, pressurized cooking for faster, juicier results.

- Deep fryer or heavy pot - Essential for holding and heating large quantities of oil at precise temperatures.

- Cooking thermometer - Ensures oil temperature remains steady between 325degF and 375degF for optimal frying.

- Pressure fryer - Designed to seal and pressurize the cooking chamber, allowing faster cooking and moisture retention.

Pros and Cons: Deep-Frying vs Pressure-Frying Poultry

Deep-frying poultry creates a crispy, golden exterior with a rich flavor, but it often results in higher oil absorption and uneven cooking. Pressure-frying cooks poultry faster and more evenly by using steam pressure, reducing oil absorption while maintaining moisture inside the meat.

Deep-frying requires careful temperature control to prevent undercooking or greasy texture, posing safety risks like oil splatters and fires. Pressure-frying uses specialized equipment, making it less accessible for home cooks but ideal for commercial kitchens aiming for tender, juicy poultry with consistent results.

Related Important Terms

Low-Oil Pressure Frying

Low-oil pressure frying for poultry combines the rapid cooking benefits of pressure frying with significantly reduced oil usage, enhancing health profiles while maintaining crispy textures and juicy interiors. This method decreases oil absorption by up to 50% compared to traditional deep-frying, offering a more efficient and eco-friendly solution without compromising flavor or cooking time.

Vacuum Frying Diffusion

Deep-frying poultry uses high-temperature oil immersion to create a crispy exterior but can result in uneven cooking and oil absorption. Vacuum frying diffusion reduces oxidation and moisture loss by lowering frying pressure, preserving flavor and nutrition more effectively than conventional deep or pressure frying methods.

Power-Crisp Poultry Technique

The Power-Crisp Poultry Technique combines pressure frying's rapid cooking and moisture retention with deep-frying's ability to create a golden, crispy crust, resulting in poultry that is juicier and more flavorful compared to traditional deep-frying alone. This method reduces cooking time by up to 25% while enhancing texture and preserving natural juices, making it a preferred choice for commercial poultry preparation.

Broaster Method

The Broaster Method combines deep-frying with pressure cooking, resulting in poultry that cooks faster while retaining juiciness and developing a crispy exterior, unlike traditional deep-frying which can lead to drier meat. Pressure-frying reduces oil absorption and enhances flavor by maintaining a sealed cooking environment, making it superior for achieving tender, flavorful poultry.

Accelerated Moisture Retention

Pressure-frying significantly accelerates moisture retention in poultry by combining high heat with increased pressure, which traps steam inside the meat, resulting in juicier and more tender meat compared to traditional deep-frying. This method reduces cooking time and prevents excessive moisture loss, enhancing flavor and texture while maintaining a crispy exterior.

High-Pressure Fryer Lock

The High-Pressure Fryer Lock ensures safety by preventing the opening of the pressure fryer during operation, maintaining optimal cooking conditions for poultry and reducing the risk of burns or accidents. This feature enhances the efficiency of pressure-frying compared to traditional deep-frying by locking in moisture and flavor while achieving faster, more consistent results.

Hyper-Crisp Coating Layer

Pressure-frying creates a thicker, hyper-crisp coating layer on poultry by sealing moisture within while rapidly frying under high pressure, resulting in a juicier interior and crunchier exterior compared to traditional deep-frying. The high-pressure environment reduces oil absorption and enhances the Maillard reaction, producing a golden-brown crust with superior texture and flavor retention.

Fast Thermal Penetration

Pressure-frying offers faster thermal penetration than traditional deep-frying, significantly reducing cooking time while maintaining juiciness in poultry. The sealed environment at elevated pressure raises the boiling point of water, allowing heat to transfer more rapidly and evenly throughout the meat.

Controlled Steam Infusion Frying

Controlled Steam Infusion Frying enhances traditional deep-frying by combining pressurized steam with hot oil, resulting in faster cooking times and juicier, tender poultry compared to standard deep-frying methods. This technique reduces oil absorption and improves texture, offering a healthier and more efficient alternative to conventional pressure-frying without compromising flavor or crispiness.

Deep-frying vs Pressure-frying for poultry. Infographic

cookingdiff.com

cookingdiff.com