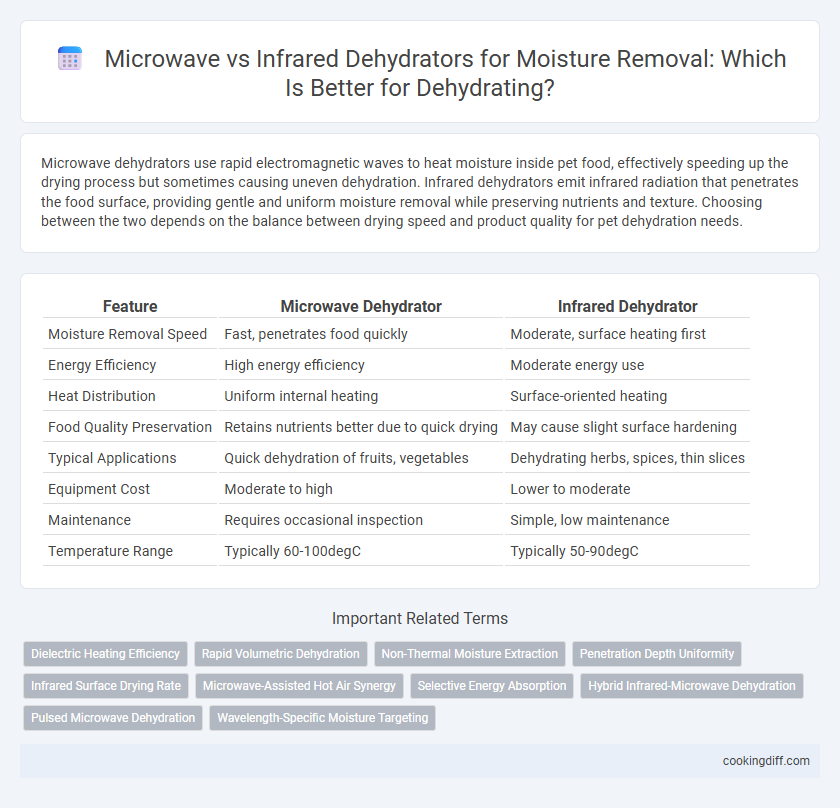

Microwave dehydrators use rapid electromagnetic waves to heat moisture inside pet food, effectively speeding up the drying process but sometimes causing uneven dehydration. Infrared dehydrators emit infrared radiation that penetrates the food surface, providing gentle and uniform moisture removal while preserving nutrients and texture. Choosing between the two depends on the balance between drying speed and product quality for pet dehydration needs.

Table of Comparison

| Feature | Microwave Dehydrator | Infrared Dehydrator |

|---|---|---|

| Moisture Removal Speed | Fast, penetrates food quickly | Moderate, surface heating first |

| Energy Efficiency | High energy efficiency | Moderate energy use |

| Heat Distribution | Uniform internal heating | Surface-oriented heating |

| Food Quality Preservation | Retains nutrients better due to quick drying | May cause slight surface hardening |

| Typical Applications | Quick dehydration of fruits, vegetables | Dehydrating herbs, spices, thin slices |

| Equipment Cost | Moderate to high | Lower to moderate |

| Maintenance | Requires occasional inspection | Simple, low maintenance |

| Temperature Range | Typically 60-100degC | Typically 50-90degC |

Introduction to Microwave and Infrared Dehydrators

Microwave dehydrators utilize electromagnetic waves at specific frequencies to rapidly heat and evaporate moisture from food by agitating water molecules at a molecular level. This technology enables faster drying times compared to conventional methods while maintaining nutrient retention.

Infrared dehydrators employ infrared radiation to transfer heat directly to the food surface, causing moisture to evaporate efficiently through conduction and radiation. Their precise temperature control and deep penetration make them ideal for uniform drying without overheating the product.

How Microwave Dehydrators Work

How do microwave dehydrators effectively remove moisture from food? Microwave dehydrators use electromagnetic waves to agitate water molecules within the food, generating heat from the inside out. This rapid internal heating accelerates moisture evaporation, resulting in faster dehydration compared to traditional methods.

How Infrared Dehydrators Work

Infrared dehydrators use radiant heat to penetrate food items, causing water molecules to vibrate and evaporate moisture efficiently. This method allows for uniform drying at lower temperatures compared to microwave dehydrators, preserving nutrient content and texture. Infrared waves target moisture directly, making the dehydration process faster and more energy-efficient.

Moisture Removal Efficiency: Microwave vs Infrared

Microwave dehydrators use electromagnetic waves to excite water molecules, resulting in rapid and uniform moisture removal with high energy efficiency. Infrared dehydrators rely on radiant heat to penetrate the surface, causing slower moisture evaporation that may lead to uneven drying and longer processing times. Studies show microwave dehydration can reduce drying time by up to 50% compared to infrared methods, enhancing overall moisture removal efficiency for food and pharmaceutical applications.

Nutrient Retention in Dehydrated Foods

Microwave dehydrators use rapid electromagnetic waves that penetrate food, significantly reducing drying time and better preserving heat-sensitive nutrients like vitamins C and B-complex. Infrared dehydrators rely on surface heating which may cause longer exposure to heat, potentially leading to greater nutrient degradation during moisture removal.

- Microwave Efficiency - Accelerates drying to minimize nutrient loss by reducing exposure time.

- Infrared Heat Penetration - Provides slower heat transfer, which can cause diminished retention of sensitive nutrients.

- Nutrient Preservation - Microwave dehydration tends to maintain higher levels of antioxidants and enzymes compared to infrared methods.

Selecting a microwave dehydrator enhances nutritional quality in dried foods by optimizing moisture removal and nutrient retention.

Energy Consumption and Operating Costs

Microwave dehydrators typically consume less energy due to faster moisture removal, reducing overall operating time and costs. Their efficient heating mechanism targets water molecules directly, leading to lower electricity usage compared to traditional methods.

Infrared dehydrators use radiant heat to remove moisture, which can result in higher energy consumption and longer drying cycles. Operating costs tend to increase with infrared units because of prolonged usage and less targeted energy application.

Drying Time Comparison

Microwave dehydrators significantly reduce drying time by using high-frequency waves to rapidly remove moisture from food. Infrared dehydrators rely on radiant heat, resulting in a slower but more uniform drying process.

Microwave dehydration can cut drying time by up to 70% compared to infrared methods, making it ideal for quick moisture removal. Infrared dehydrators require longer exposure, often extending the drying period to preserve texture and nutrients. Choosing between the two depends on balancing speed and quality in the dehydration process.

Impact on Food Texture and Flavor

| Microwave dehydrators rapidly remove moisture by agitating water molecules, preserving food texture with minimal shrinkage and retaining vibrant flavors due to short exposure times. |

| Infrared dehydrators use radiant heat to gently evaporate moisture, often enhancing food texture by maintaining surface crispness and intensifying natural flavors through slow, even drying. |

| Microwave drying can sometimes cause uneven texture if not carefully controlled, whereas infrared drying tends to produce more uniform results but requires longer drying periods. |

Suitability for Different Food Types

Microwave dehydrators excel in rapidly removing moisture from high-water-content fruits and vegetables, preserving nutrients and texture. Infrared dehydrators provide more uniform drying, making them ideal for dense or thicker food items like meats and herbs.

- Microwave dehydrators - Best suited for foods with high moisture due to quick heat penetration and efficient evaporation.

- Infrared dehydrators - Provide consistent surface heating, ideal for dense foods requiring gradual moisture removal.

- Food versatility - Infrared units handle a broader range of textures, while microwaves are optimized for delicate, moisture-rich produce.

Related Important Terms

Dielectric Heating Efficiency

Microwave dehydrators exhibit superior dielectric heating efficiency by directly energizing water molecules within the food, resulting in faster and more uniform moisture removal compared to infrared dehydrators that rely on surface heating. This targeted energy absorption minimizes drying time and preserves nutritional quality through reduced thermal gradients.

Rapid Volumetric Dehydration

Microwave dehydrators achieve rapid volumetric dehydration by using dielectric heating to uniformly remove moisture from food at a molecular level, significantly reducing drying time compared to surface-heating infrared dehydrators. Infrared dehydrators rely on radiant heat that penetrates food surfaces, leading to slower moisture removal and potential uneven drying due to limited internal heat distribution.

Non-Thermal Moisture Extraction

Microwave dehydrators utilize electromagnetic waves to agitate water molecules, enabling faster and more energy-efficient moisture removal without raising the product's temperature, preserving nutritional and sensory qualities. Infrared dehydrators rely on radiant heat to evaporate moisture, which may cause slight thermal effects, making microwave technology superior for non-thermal moisture extraction in delicate food products.

Penetration Depth Uniformity

Microwave dehydrators offer deeper penetration depth by using electromagnetic waves that excite water molecules throughout the material uniformly, leading to faster and more consistent moisture removal. Infrared dehydrators primarily heat the surface, resulting in less uniform moisture reduction and potential uneven drying in thicker samples.

Infrared Surface Drying Rate

Infrared dehydrators achieve faster surface drying rates by directly heating moisture molecules through radiant energy, enhancing water vaporization efficiency compared to microwaves that volumetrically heat the material. This focused surface heating in infrared systems results in quicker moisture removal, improved texture preservation, and reduced overall drying times.

Microwave-Assisted Hot Air Synergy

Microwave-assisted hot air synergy in dehydrators combines rapid moisture evaporation from microwave energy with uniform heat distribution from hot air, significantly reducing drying time and preserving nutrient quality compared to infrared methods. This hybrid approach enhances energy efficiency and prevents surface hardening, making it ideal for moisture removal in heat-sensitive food products.

Selective Energy Absorption

Microwave dehydrators utilize selective energy absorption by targeting water molecules directly, enabling rapid internal moisture removal with minimal heat damage to the product. In contrast, infrared dehydrators apply radiant heat absorbed primarily by the surface, resulting in slower moisture evaporation but better preservation of texture and nutrients.

Hybrid Infrared-Microwave Dehydration

Hybrid infrared-microwave dehydration combines the rapid heating of microwave energy with the surface drying efficiency of infrared radiation, enhancing moisture removal while preserving nutritional quality and texture. This synergistic method reduces drying time significantly compared to traditional dehydrators and improves energy efficiency by targeting both internal and surface moisture simultaneously.

Pulsed Microwave Dehydration

Pulsed microwave dehydration offers rapid and uniform moisture removal by generating volumetric heating, which significantly reduces drying time compared to infrared dehydrators relying on surface heat transfer. This method enhances energy efficiency and preserves product quality by minimizing thermal degradation and preventing surface overheating inherent in infrared dehydration processes.

Microwave vs Infrared dehydrator for moisture removal. Infographic

cookingdiff.com

cookingdiff.com