Traditional jars provide a simple and cost-effective option for fermenting pet food, allowing natural anaerobic fermentation through airtight sealing and consistent temperature control. Olor fermenters, designed specifically for pet food, offer advanced odor control and tailored airflow systems to minimize unpleasant smells during the fermentation process. Choosing between the two depends on the need for convenience and odor management versus budget and simplicity in fermenting pet food.

Table of Comparison

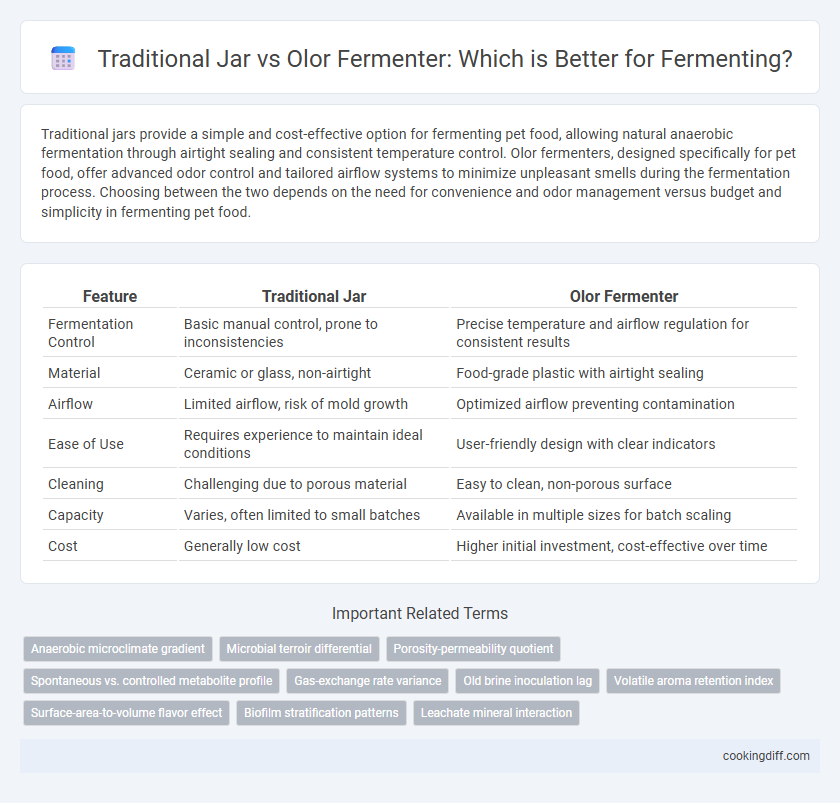

| Feature | Traditional Jar | Olor Fermenter |

|---|---|---|

| Fermentation Control | Basic manual control, prone to inconsistencies | Precise temperature and airflow regulation for consistent results |

| Material | Ceramic or glass, non-airtight | Food-grade plastic with airtight sealing |

| Airflow | Limited airflow, risk of mold growth | Optimized airflow preventing contamination |

| Ease of Use | Requires experience to maintain ideal conditions | User-friendly design with clear indicators |

| Cleaning | Challenging due to porous material | Easy to clean, non-porous surface |

| Capacity | Varies, often limited to small batches | Available in multiple sizes for batch scaling |

| Cost | Generally low cost | Higher initial investment, cost-effective over time |

Overview: Traditional Jars vs. Olor Fermenters

What are the key differences between traditional jars and Olor fermenters for fermenting? Traditional jars, commonly made of ceramic or glass, offer a simple, airtight environment ideal for slow fermentation processes. Olor fermenters incorporate advanced materials and design features that enhance airflow control and temperature stability, promoting faster and more consistent fermentation results.

Material Comparison: Clay, Glass, and Modern Plastics

Traditional jars crafted from clay offer natural breathability that enhances fermentation by allowing gases to escape while maintaining moisture balance. In contrast, glass fermenters provide a non-porous, inert surface that prevents contamination and allows for easy monitoring of the fermentation process.

Modern plastic fermenters, typically made from food-grade polypropylene or polyethylene, combine durability with lightweight convenience, though they may be prone to scratches that harbor bacteria. Clay's porous nature can influence microbial activity uniquely, whereas glass and plastic ensure consistent inert environments that preserve flavor profiles. Selecting the right material depends on balancing breathability, ease of cleaning, and fermentation control.

Fermentation Process Differences

Traditional jars retain temperature and limit oxygen exposure, promoting anaerobic fermentation essential for kimchi and sauerkraut. Olor fermenters offer controlled air circulation, enhancing aerobic fermentation for kombucha and sourdough starters.

- Oxygen Control - Traditional jars create an airtight environment to reduce oxygen, which encourages lactic acid bacteria growth.

- Airflow Regulation - Olor fermenters provide adjustable airflow to balance yeast and bacteria during fermentation.

- Temperature Stability - Traditional jars maintain stable internal temperature, fostering consistent fermentation rates.

Oxygen Flow Control and Airlock Mechanisms

Traditional jars rely on simple airlock mechanisms that limit oxygen exposure through water-sealed systems, which can lead to variable oxygen flow during fermentation. Olor fermenters integrate advanced oxygen flow control with precision airlock designs, ensuring consistent anaerobic environments to optimize microbial activity.

- Traditional Jar Airlock - Utilizes a basic water-seal that allows CO2 to escape while limiting oxygen ingress passively.

- Oxygen Flow Control - Olor fermenters adjust oxygen levels actively to maintain ideal conditions for fermentation without contamination.

- Airlock Mechanisms - Advanced seals in olor fermenters reduce air exchange variability compared to traditional jar systems.

Optimized oxygen management in olor fermenters results in more reliable fermentation outcomes and reduced spoilage risk.

Flavor and Aroma Impacts

Traditional jars often enhance fermentation by promoting more consistent microbial activity, which can deepen the flavor and aroma profiles. Olor fermenters, designed with advanced air circulation, tend to produce brighter and more complex aroma notes during fermentation.

- Traditional jar retains heat effectively - This steady temperature results in richer, earthier flavors in fermented products.

- Olor fermenter improves oxygen flow - Enhanced oxygen levels stimulate diverse microbial communities, producing vibrant and layered aromas.

- Material composition influences taste - Ceramic in traditional jars imparts subtle mineral notes, whereas odorless materials in olor fermenters allow pure flavor expression.

Ease of Use and Maintenance

| Traditional Jar | Simple design ensures ease of use with minimal moving parts; requires frequent cleaning to prevent residue build-up and maintain fermentation quality. |

| Olor Fermenter | Engineered for user-friendly operation with features like airtight seals and easy-pour spouts; maintenance is streamlined with detachable components designed for thorough cleaning. |

Batch Size and Storage Capacity

Traditional jars typically hold smaller batch sizes, ranging from 1 to 5 gallons, making them suitable for home fermentation projects. Olor fermenters offer larger storage capacity, often exceeding 20 gallons, ideal for commercial or large-scale fermentation. The increased capacity of olor fermenters allows for consistent environmental control and efficient batch processing, enhancing fermentation quality and scalability.

Cost Considerations and Lifespan

Traditional fermentation jars typically cost less upfront, making them accessible for beginners and small-scale fermenters. Their simple design requires minimal maintenance, but frequent replacements may be necessary due to potential breakage or wear over time.

Olor fermenters often involve a higher initial investment, reflecting their advanced materials and robust construction. These fermenters boast extended lifespan and durability, which can reduce long-term costs despite the initial price difference.

Traditional vs. Moden Aesthetic & Cultural Values

Traditional jars used for fermenting reflect deep-rooted cultural heritage and artisanal craftsmanship, often featuring rustic designs that emphasize connection to ancestral methods. Modern olor fermenters offer sleek, minimalist aesthetics that appeal to contemporary tastes while integrating advanced materials for durability and efficiency. The contrast between traditional and modern fermenting vessels highlights evolving preferences balancing historical authenticity with modern functionality and style.

Related Important Terms

Anaerobic microclimate gradient

Traditional jars create a relatively uniform anaerobic environment that supports consistent fermentation but may limit oxygen gradient complexity. Olor fermenters establish a more dynamic anaerobic microclimate gradient, enhancing microbial diversity and promoting more nuanced fermentation profiles.

Microbial terroir differential

Traditional jars harbor diverse native microbial communities shaped by local environmental factors, creating a unique microbial terroir that influences fermentation profiles and flavors. Olor fermenters, designed with controlled aeration and materials, tend to select for specific microbial populations, resulting in more consistent but less regionally distinctive fermentation outcomes.

Porosity-permeability quotient

Traditional jars exhibit a low porosity-permeability quotient, limiting gas exchange and slowing fermentation rates, while olor fermenters are engineered with higher porosity materials that enhance airflow and microbial activity. This optimized porosity-permeability balance in olor fermenters results in more consistent fermentation outcomes and accelerated breakdown of organic substrates.

Spontaneous vs. controlled metabolite profile

Traditional jars support spontaneous fermentation by allowing natural microbes to develop a diverse metabolite profile, leading to complex and unique flavors. Olor fermenters offer controlled environments that regulate temperature and aeration, producing consistent and predictable metabolite profiles for standardized fermentation outcomes.

Gas-exchange rate variance

Traditional jars offer limited gas-exchange rates due to their airtight seals, often causing slower fermentation and potential off-flavors from gas buildup. Olor fermenters are designed with enhanced airflow systems that facilitate optimal gas exchange, promoting faster fermentation and consistent flavor development.

Old brine inoculation lag

Traditional jars often experience a longer old brine inoculation lag due to limited oxygen exchange and inconsistent microbial contact, which can slow fermentation startup. Olor fermenters optimize airflow and maintain stable microbial environments, significantly reducing lag time by enhancing inoculation efficiency and accelerating the fermentation process.

Volatile aroma retention index

Traditional jars often exhibit a lower volatile aroma retention index due to limited sealing capabilities, leading to the loss of key aromatic compounds during fermentation. In contrast, Olor fermenters provide enhanced airtight conditions, significantly preserving the volatile aroma profile crucial for high-quality fermented products.

Surface-area-to-volume flavor effect

Traditional jars provide a higher surface-area-to-volume ratio, promoting faster fermentation and more complex flavor development due to increased oxygen exposure. Olor fermenters, with their lower surface-area-to-volume ratio, yield a slower fermentation process that enhances depth and mellowness in the final taste profile.

Biofilm stratification patterns

Traditional jars for fermenting typically exhibit uneven biofilm stratification patterns due to limited airflow and surface area, which can result in inconsistent microbial activity. Olor fermenters, designed with enhanced ventilation and optimized geometry, promote uniform biofilm development, improving fermentation efficiency and flavor complexity.

Traditional jar vs olor fermenter for fermenting. Infographic

cookingdiff.com

cookingdiff.com