Standard lids for pressure-cooking provide a secure, airtight seal essential for maintaining high pressure and ensuring efficient cooking times, while glass lids offer the advantage of visibility to monitor the pet's food without releasing steam or pressure. Glass lids often lack the pressure-sealing capability, making them best suited for slow cooking or simmering rather than true pressure-cooking. Choosing between a standard lid and a glass lid depends on whether the primary need is high-pressure cooking efficiency or the ability to visually check the pet's meal during the process.

Table of Comparison

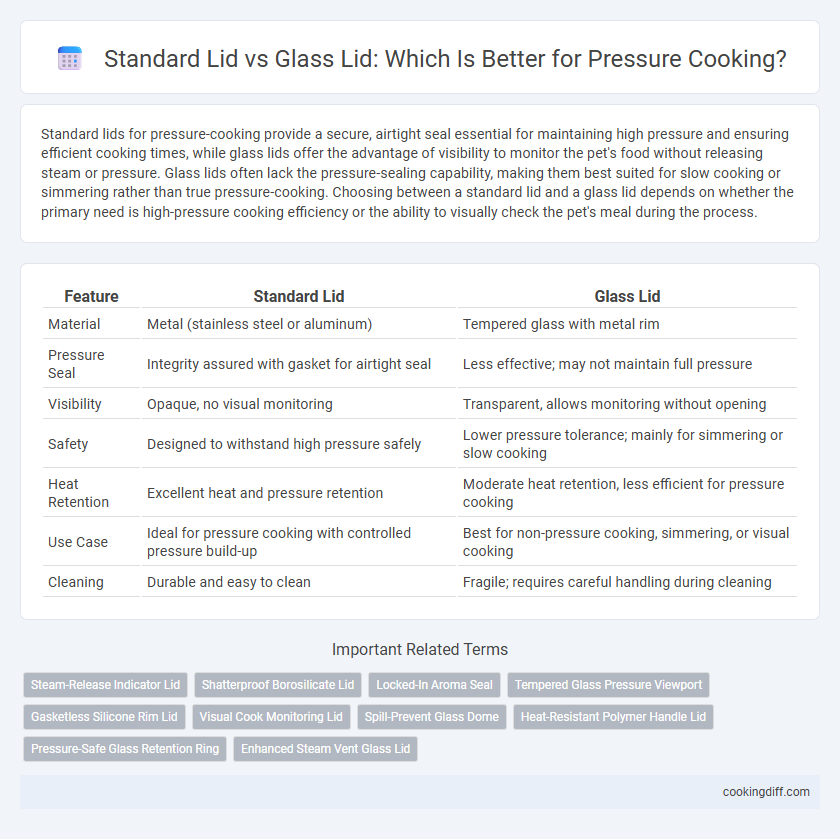

| Feature | Standard Lid | Glass Lid |

|---|---|---|

| Material | Metal (stainless steel or aluminum) | Tempered glass with metal rim |

| Pressure Seal | Integrity assured with gasket for airtight seal | Less effective; may not maintain full pressure |

| Visibility | Opaque, no visual monitoring | Transparent, allows monitoring without opening |

| Safety | Designed to withstand high pressure safely | Lower pressure tolerance; mainly for simmering or slow cooking |

| Heat Retention | Excellent heat and pressure retention | Moderate heat retention, less efficient for pressure cooking |

| Use Case | Ideal for pressure cooking with controlled pressure build-up | Best for non-pressure cooking, simmering, or visual cooking |

| Cleaning | Durable and easy to clean | Fragile; requires careful handling during cleaning |

Standard vs Glass Lids: A Pressure-Cooking Overview

Standard lids for pressure cookers are designed to create a tight seal necessary for maintaining high-pressure steam, ensuring faster cooking times and efficient energy use. Glass lids, while allowing visibility of the cooking process, typically cannot withstand the high pressures required and are better suited for simmering or low-pressure cooking. Choosing between standard and glass lids depends on the cooking method: pressure cooking requires a standard lid for safety and optimal performance, whereas glass lids offer convenience for monitoring during non-pressure cooking tasks.

Material Composition: Metal Standard Lids vs Glass Lids

Standard pressure-cooking lids are typically made from durable metal alloys designed to withstand high temperatures and pressures. Glass lids, however, feature tempered glass with metal rims, allowing visibility while maintaining strength.

- Metal durability - Metal lids provide excellent heat resistance and ensure a secure seal necessary for maintaining pressure.

- Visibility advantage - Glass lids allow cooks to monitor the cooking process without releasing steam or pressure.

- Safety and maintenance - Metal lids generally require less careful handling than glass and are less prone to damage from drops or impacts.

Safety Features: Which Lid Keeps You Safer?

Standard lids for pressure cookers typically feature locking mechanisms and pressure release valves that prevent accidental opening under high pressure, enhancing user safety. Glass lids, while allowing visual monitoring, usually lack secure locking systems and pressure gauges, making them less reliable for pressure-cooking safety. Choosing a pressure cooker with a standard lid ensures better protection against pressure-related accidents and steam burns.

Visibility During Cooking: The Transparency Advantage

How does visibility during cooking differ between a standard lid and a glass lid in pressure-cooking? A glass lid offers clear transparency, allowing for easy monitoring of the cooking process without interrupting heat and pressure. Standard lids require lifting to check food, which can result in heat loss and longer cooking times.

Steam Retention and Pressure Integrity Comparison

Standard lids on pressure cookers are engineered to maintain optimal steam retention and ensure maximum pressure integrity during cooking. Glass lids, while offering visibility, typically sacrifice some steam retention and pressure stability, making them less suitable for high-pressure cooking.

- Standard lid steam retention - Designed with secure sealing mechanisms to trap steam efficiently and prevent pressure loss.

- Glass lid pressure integrity - May struggle to maintain consistent pressure due to less robust sealing compared to metal lids.

- Pressure cooking performance - Standard lids facilitate faster cooking times by preserving internal pressure effectively, unlike glass lids.

Durability and Lifespan: Standard Lid vs Glass Lid

Standard lids for pressure cookers are typically crafted from stainless steel, offering superior durability and resistance to high pressure compared to glass lids. Glass lids, while convenient for monitoring cooking progress, often have a shorter lifespan due to their susceptibility to cracking or breaking under intense heat and pressure.

Stainless steel standard lids can withstand repeated use over many years without warping or corrosion, making them ideal for frequent pressure cooking. Glass lids are more prone to damage from thermal shock and require careful handling to maintain their integrity. Choosing a standard lid ensures long-term reliability and safety during high-pressure cooking sessions.

Cleaning and Maintenance Differences

| Aspect | Standard Lid | Glass Lid |

|---|---|---|

| Cleaning | Typically requires thorough scrubbing to remove food residues and steam build-up. Sealing rings may need individual cleaning or replacement to maintain pressure efficiency. | Easy to clean due to smooth, non-porous surface; visibility allows users to spot dirt or residue quickly. Usually dishwasher safe, simplifying maintenance. |

| Maintenance | Regular inspection of valves and gasket seals is necessary to ensure safety and proper function. Parts may need occasional replacement due to wear and tear from high pressure use. | Less frequent internal maintenance; however, glass lids are more prone to chips or cracks, requiring careful handling. Gaskets and seals might not be as critical as in standard lids due to different cooking methods. |

Compatibility with Modern Pressure Cookers

Standard lids are designed specifically for pressure-sealing and safety, ensuring compatibility with modern pressure cookers' locking mechanisms. Glass lids offer visibility but often lack the pressure-sealing features required for safe pressure cooking on contemporary models.

- Sealing Efficiency - Standard lids provide airtight seals essential for pressure buildup, whereas glass lids typically do not.

- Safety Mechanisms - Modern pressure cookers incorporate locking features compatible only with standard lids to prevent accidents.

- Usage Versatility - Glass lids are suitable for slow cooking or steaming but not for pressure cooking in advanced appliances.

Choosing a lid compatible with your pressure cooker's design ensures safe and optimal cooking performance.

Price and Value Considerations

Standard pressure cooker lids generally cost less than glass lids, making them a budget-friendly choice for most users. Their robust construction ensures a secure seal essential for high-pressure cooking, providing reliability without extra expense.

Glass lids, while pricier, offer the advantage of visibility, allowing cooks to monitor food without releasing pressure. This feature enhances convenience and can be seen as added value despite the higher initial investment.

Related Important Terms

Steam-Release Indicator Lid

The steam-release indicator lid ensures safety by visibly signaling when pressure has been properly released, unlike standard lids or glass lids that lack this feature. This lid type enhances pressure-cooking control and prevents accidental opening, improving overall kitchen safety and efficiency.

Shatterproof Borosilicate Lid

Shatterproof borosilicate lids offer superior durability and heat resistance compared to standard glass lids, minimizing the risk of breakage during pressure cooking. These lids provide clear visibility of the cooking process while ensuring safety and maintaining consistent pressure inside the cooker.

Locked-In Aroma Seal

A standard lid for pressure-cooking features a locked-in aroma seal that preserves flavors and moisture by creating an airtight environment, enhancing the dish's taste and texture. In contrast, a glass lid lacks this airtight seal, resulting in less effective pressure buildup and potential aroma loss during cooking.

Tempered Glass Pressure Viewport

Tempered glass pressure viewports in glass lids enable real-time monitoring of cooking progress without releasing steam, enhancing safety and precision during pressure cooking. Standard lids, typically solid metal, provide a secure seal for maintaining high pressure but lack visibility, requiring lid removal to check food status.

Gasketless Silicone Rim Lid

The gasketless silicone rim lid offers an innovative alternative to standard lids and glass lids in pressure cooking by eliminating the need for a traditional rubber gasket, thereby reducing wear and tear and simplifying maintenance. Its airtight seal ensures consistent pressure levels, enhancing cooking efficiency while allowing visual monitoring similar to glass lids without compromising safety.

Visual Cook Monitoring Lid

A glass lid for pressure-cooking allows clear visual monitoring of the cooking process without releasing steam or pressure, enhancing safety and convenience. In contrast, a standard lid seals tightly but obscures the view, requiring reliance on pressure indicators and timers to gauge progress.

Spill-Prevent Glass Dome

The Spill-Prevent Glass Dome lid offers clear visibility during pressure-cooking, allowing you to monitor food progress without releasing steam and compromising cooking pressure. Unlike standard lids, the spill-prevent feature minimizes messes by securely containing boiling liquids and preventing accidental spills inside the cooker.

Heat-Resistant Polymer Handle Lid

Heat-resistant polymer handle lids for pressure cookers offer enhanced durability and safety compared to standard glass lids, as they withstand high temperatures without cracking or warping. These lids provide a secure grip and improved heat insulation, ensuring safe handling during intense pressure-cooking processes.

Pressure-Safe Glass Retention Ring

A pressure-safe glass retention ring in pressure-cooking lids provides visibility without compromising safety, maintaining a secure seal under high pressure unlike standard glass lids lacking this feature. Standard lids typically rely on metal or silicone sealing rings designed specifically to withstand intense pressure, ensuring consistent performance and safety during cooking cycles.

Standard lid vs Glass lid for pressure-cooking. Infographic

cookingdiff.com

cookingdiff.com