Using a basting brush for roasting allows precise application of marinades or oils, ensuring even coating on the pet's surface for enhanced flavor and moisture retention. An oil sprayer provides a fine, uniform mist that helps to avoid over-saturating the meat while promoting a crispy, golden exterior. Choosing between them depends on the desired level of control and texture during the roasting process.

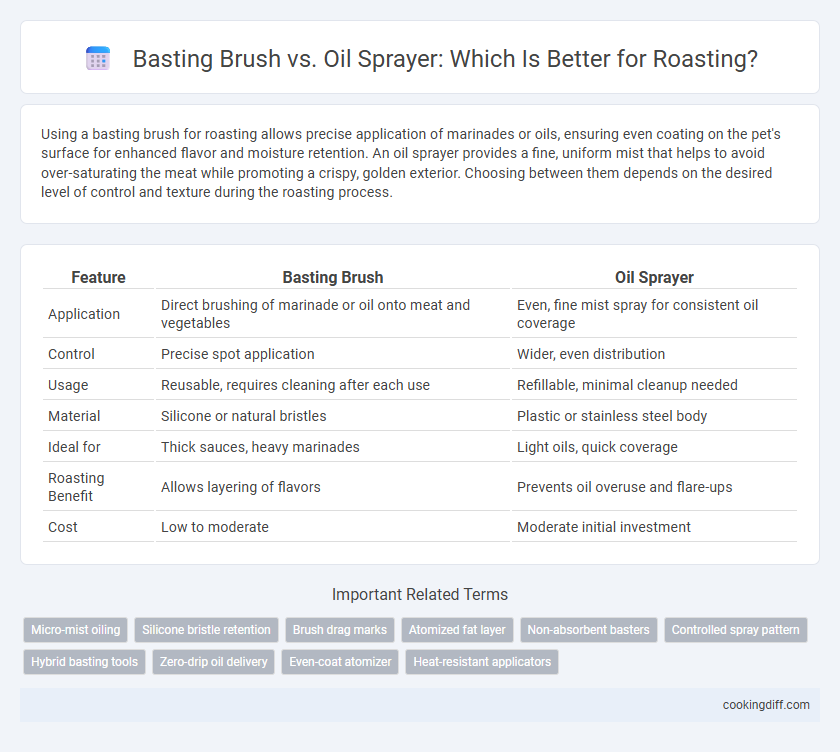

Table of Comparison

| Feature | Basting Brush | Oil Sprayer |

|---|---|---|

| Application | Direct brushing of marinade or oil onto meat and vegetables | Even, fine mist spray for consistent oil coverage |

| Control | Precise spot application | Wider, even distribution |

| Usage | Reusable, requires cleaning after each use | Refillable, minimal cleanup needed |

| Material | Silicone or natural bristles | Plastic or stainless steel body |

| Ideal for | Thick sauces, heavy marinades | Light oils, quick coverage |

| Roasting Benefit | Allows layering of flavors | Prevents oil overuse and flare-ups |

| Cost | Low to moderate | Moderate initial investment |

Introduction to Roasting Essentials

The basting brush allows precise application of marinades, oils, or butter directly onto meat, enhancing flavor and moisture during roasting. Its bristles hold sauces well, providing controlled coverage and preventing excessive dripping.

Oil sprayers evenly distribute a fine mist of oil over the roasting surface, promoting uniform browning and a crisp exterior without adding too much fat. They are especially useful for large cuts or vegetables, ensuring consistent roasting results.

What is a Basting Brush?

A basting brush is a kitchen tool designed to apply sauces, oils, or marinades evenly onto food during roasting, ensuring enhanced flavor and moisture retention. Typically made with silicone or natural bristles, it allows for precise control over the application process.

Unlike an oil sprayer that distributes a fine mist, a basting brush can deposit thicker coatings or glazes without excessive dripping. This makes it ideal for tasks like spreading melted butter, barbecue sauce, or herb-infused oils on meats and vegetables while roasting.

What is an Oil Sprayer?

What is an oil sprayer and how does it differ from a basting brush for roasting? An oil sprayer is a kitchen tool designed to evenly distribute fine misted oil over food, ensuring a light and consistent coating. Unlike a basting brush that can apply uneven layers and absorb excess oil, an oil sprayer allows better control and reduces oil waste during roasting.

How Basting Brushes Enhance Roasting

Basting brushes are essential for evenly coating meats and vegetables with marinades or melted butter, ensuring rich flavor and a moist texture during roasting. Their soft bristles allow precise application, preventing glaze pooling and promoting uniform browning.

The ability of basting brushes to absorb and distribute liquids enhances caramelization and prevents drying out, which oil sprayers may not achieve as effectively. Sprayers provide a fine mist suitable for light oiling but lack the control needed for thorough, targeted basting. This precision makes basting brushes superior for maintaining juiciness and developing deep, savory crusts on roasted dishes.

Advantages of Using Oil Sprayers for Roasting

Oil sprayers provide an even and controlled distribution of oil, enhancing the roasting process by preventing uneven cooking and reducing excessive oil usage. They create a fine mist that can reach all surfaces of the food, ensuring a crispier texture and better caramelization. Using an oil sprayer also promotes healthier cooking by minimizing oil consumption and reducing calorie intake compared to traditional basting brushes.

Comparing Coverage: Brush vs Sprayer

Basting brushes provide targeted coverage, allowing for precise application of marinades or oils directly onto meat or vegetables during roasting. Oil sprayers distribute a fine, even mist over a larger surface area, ensuring uniform coverage and helping to reduce the amount of oil used. Choosing between a brush and a sprayer depends on the desired control and coverage: brushes excel in detailed basting while sprayers offer quick, consistent oil application.

Health Considerations: Oil Control and Usage

| Health Considerations: | Basting brushes allow precise control over oil application, minimizing excess fat absorption during roasting. Oil sprayers distribute a fine mist, promoting even coverage and reducing the overall amount of oil used, which supports healthier cooking. Selecting between these tools depends on the desired oil control level and preference for application uniformity to maintain health-conscious roasting. |

Ease of Cleaning and Maintenance

Basting brushes typically require thorough cleaning to remove oil and food residue from bristles, making maintenance more time-consuming. Oil sprayers feature simple, often dishwasher-safe components that allow for quicker and easier cleaning after roasting.

- Basting brush bristles trap residue - This makes it necessary to scrub multiple times to ensure hygienic use.

- Oil sprayer parts are detachable - Allowing for convenient rinsing and less buildup over time.

- Non-stick materials in sprayers simplify cleaning - Preventing oil from clinging to surfaces and reducing maintenance efforts.

Best Uses: When to Choose Brush or Sprayer

Basting brushes are ideal for applying thick marinades or sauces evenly during roasting, while oil sprayers excel at distributing a fine, uniform mist of oil for crispier results. Choosing between them depends on the desired texture and precision of oil or marinade application.

- Basting Brush for Thick Coatings - Perfect for spreading viscous sauces or butter without dripping, enhancing flavor layers.

- Oil Sprayer for Even Coverage - Delivers a consistent, thin layer of oil that promotes even roasting and browning.

- Precision vs. Volume Control - Brushes allow targeted application, sprayers provide broad, quick oil distribution.

Related Important Terms

Micro-mist oiling

A micro-mist oil sprayer evenly distributes a fine layer of oil over roasting surfaces, enhancing caramelization and preventing food from sticking without oversaturating. Unlike basting brushes, which can leave uneven oil patches and absorbed residues, micro-mist sprayers ensure consistent oil coverage, promoting uniform heat transfer and optimal browning.

Silicone bristle retention

Silicone basting brushes offer superior bristle retention during roasting compared to traditional oil sprayers, preventing bristle shedding and ensuring even application of marinades and oils. Their heat-resistant silicone bristles maintain shape and durability under high temperatures, enhancing efficiency and food safety.

Brush drag marks

Basting brushes can leave drag marks on meat surfaces, creating uneven textures that affect roasting appearance and moisture retention. Oil sprayers apply a fine, uniform mist that enhances browning without disrupting the meat's natural surface, ensuring consistent roasting results.

Atomized fat layer

A basting brush applies fat in thicker, uneven layers that can lead to inconsistent roasting results, while an oil sprayer creates a fine, atomized fat layer ensuring even coverage and enhanced caramelization. The atomized mist from sprayers promotes uniform heat distribution and better moisture retention for perfectly roasted dishes.

Non-absorbent basters

Non-absorbent basting brushes retain and distribute marinade evenly without soaking up excess oil, ensuring consistent flavor and moisture during roasting. Oil sprayers provide a fine, uniform coating that enhances browning while reducing waste and preventing greasy buildup on roasted foods.

Controlled spray pattern

Basting brushes offer precise control for evenly coating roasting meats with marinades or oils, allowing targeted application to specific areas. Oil sprayers deliver a fine, uniform mist that covers large surfaces quickly but may lack the pinpoint accuracy needed for detailed basting tasks.

Hybrid basting tools

Hybrid basting tools combine the precision of a basting brush with the even distribution of an oil sprayer, enhancing flavor and moisture retention during roasting. These versatile tools allow controlled application of marinades and oils, reducing waste while ensuring consistent coverage for perfectly roasted dishes.

Zero-drip oil delivery

A basting brush offers precise control but can cause uneven oil application and drip messes, whereas an oil sprayer provides a zero-drip oil delivery system ensuring even coverage and minimal waste during roasting. This efficient spraying method enhances flavor infusion and maintains a cleaner cooking environment.

Even-coat atomizer

An even-coat atomizer, like an oil sprayer, ensures uniform oil distribution across the roasting surface, preventing hot spots and promoting consistent browning. In contrast, a basting brush can leave uneven patches due to bristle absorption and inconsistent application, affecting roasting quality.

Basting brush vs Oil sprayer for roasting. Infographic

cookingdiff.com

cookingdiff.com