Sous vide cooking provides precise temperature control, allowing food to reach and maintain the exact temperature needed to eliminate harmful bacteria without overcooking, which enhances both safety and texture. In contrast, pasteurization-by-cooking relies on higher temperatures for shorter times, potentially compromising food quality while still achieving microbial safety. The controlled, low-temperature process of sous vide results in safer food with better retained nutrients and flavors compared to traditional pasteurization methods.

Table of Comparison

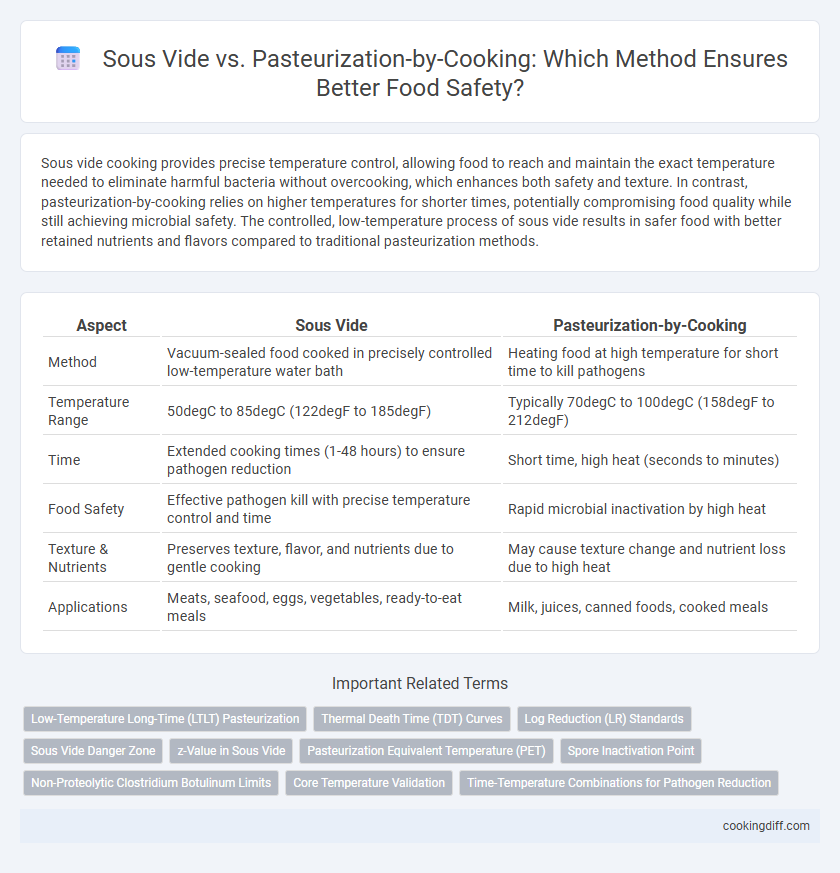

| Aspect | Sous Vide | Pasteurization-by-Cooking |

|---|---|---|

| Method | Vacuum-sealed food cooked in precisely controlled low-temperature water bath | Heating food at high temperature for short time to kill pathogens |

| Temperature Range | 50degC to 85degC (122degF to 185degF) | Typically 70degC to 100degC (158degF to 212degF) |

| Time | Extended cooking times (1-48 hours) to ensure pathogen reduction | Short time, high heat (seconds to minutes) |

| Food Safety | Effective pathogen kill with precise temperature control and time | Rapid microbial inactivation by high heat |

| Texture & Nutrients | Preserves texture, flavor, and nutrients due to gentle cooking | May cause texture change and nutrient loss due to high heat |

| Applications | Meats, seafood, eggs, vegetables, ready-to-eat meals | Milk, juices, canned foods, cooked meals |

Understanding Sous Vide: Precision Cooking Defined

Sous vide is a precision cooking method that cooks food at a controlled, low temperature for extended periods, ensuring even pasteurization while preserving texture and flavor. Unlike traditional pasteurization-by-cooking, which relies on high heat to destroy pathogens quickly, sous vide maintains a precise temperature range to safely eliminate harmful bacteria without overcooking. This approach enhances food safety and quality by combining microbiological safety standards with culinary excellence.

What Is Pasteurization-by-Cooking?

Pasteurization-by-cooking is a food safety process that involves heating food to a specific temperature for a set duration to eliminate harmful pathogens. This method ensures microbial safety while preserving the food's texture and flavor.

Unlike traditional pasteurization targeting liquids, pasteurization-by-cooking applies precise temperature controls for solid foods. It is commonly used in conjunction with sous vide techniques to achieve optimal safety and quality.

Food Safety Fundamentals: A Comparative Overview

Sous vide cooking maintains precise temperature control, ensuring pathogenic bacteria are effectively destroyed while preserving food texture and nutrients. Pasteurization-by-cooking relies on higher temperatures for shorter durations, which can sometimes compromise food quality despite ensuring safety. Both methods target food safety by reducing microbial load, but sous vide offers enhanced consistency and retention of culinary attributes.

Temperature Control: Sous Vide vs Pasteurization

| Method | Temperature Range | Precision | Food Safety Impact |

|---|---|---|---|

| Sous Vide | 50degC to 85degC (122degF to 185degF) | Highly precise temperature control within +-0.1degC | Ensures consistent pasteurization by maintaining exact temperatures for extended times, reducing bacterial risks |

| Pasteurization-by-Cooking | Typically above 70degC (158degF) | Less precise temperature regulation, often fluctuating | Relies on higher temperatures applied briefly, potentially causing uneven microbial reduction |

Time and Heat: Achieving Pathogen Reduction

Sous vide cooking uses precise low temperatures over extended times to reduce pathogens effectively while preserving food quality. Pasteurization-by-cooking relies on higher temperatures for shorter durations but may compromise texture and flavor.

Time and heat are critical factors in achieving pathogen reduction, with sous vide allowing a controlled environment that maintains consistent temperatures between 55degC and 60degC for several hours to inactivate bacteria safely. Pasteurization typically employs temperatures above 70degC for a few minutes, rapidly killing pathogens but risking overcooking. The extended low-temperature process of sous vide ensures even heat penetration, improving microbial safety without denaturing proteins extensively.

Nutrient Retention and Texture: Impact on Food Quality

Sous vide cooking preserves nutrients and texture more effectively than traditional pasteurization-by-cooking methods by using precise, low-temperature water baths. This technique maintains food quality by preventing overcooking and nutrient degradation typically caused by high heat.

- Nutrient Retention - Sous vide reduces nutrient loss by cooking food at controlled temperatures, minimizing exposure to excessive heat that destroys vitamins and minerals.

- Texture Preservation - The gentle heat in sous vide prevents protein denaturation and moisture loss, resulting in tender, juicy textures unlike the firmer textures from pasteurization-by-cooking.

- Consistent Quality - Vacuum-sealed bags in sous vide ensure even heat distribution, enhancing uniformity and food safety without compromising texture or nutritional value.

Risks and Safety in Sous Vide Methods

Sous vide cooking offers precise temperature control that can effectively eliminate pathogens when done correctly, but it requires strict adherence to time and temperature guidelines to prevent bacterial growth. Unlike traditional pasteurization-by-cooking, sous vide uses lower temperatures for longer periods, which may increase the risk if standards are not met.

- Bacterial Growth Risk - Prolonged exposure to temperatures between 40degF and 140degF can encourage harmful bacteria such as Clostridium botulinum to proliferate if vacuum sealing is incomplete.

- Temperature Control Importance - Maintaining accurate sous vide temperatures typically above 131degF for sufficient time ensures safe pasteurization by destroying most pathogens.

- Vacuum Seal Integrity - Inadequate sealing can introduce oxygen and contaminants, increasing the likelihood of spoilage or foodborne illness despite proper cooking temperatures.

Regulatory Guidelines for Food Pasteurization

Sous vide cooking adheres to strict regulatory guidelines for food pasteurization, ensuring that food is heated to precise temperatures for specific time durations to eliminate harmful pathogens. Regulatory bodies such as the USDA provide time-temperature tables that validate sous vide processes for safe pasteurization of meat, poultry, and seafood.

Pasteurization-by-cooking requires compliance with FDA and USDA standards that specify minimum internal temperatures and holding times to confirm microbial safety. Sous vide achieves these standards by maintaining consistent temperature control, minimizing the risk of underprocessing compared to traditional methods.

Home vs Commercial Applications: Choosing the Right Method

Which method offers better food safety for home cooks and commercial kitchens: sous vide or pasteurization-by-cooking? Sous vide provides precise temperature control, making it ideal for consistent results in both home and commercial settings. Pasteurization-by-cooking is often faster but may lack the uniformity in temperature essential for thorough pathogen elimination in critical applications.

Related Important Terms

Low-Temperature Long-Time (LTLT) Pasteurization

Sous vide employs precise Low-Temperature Long-Time (LTLT) pasteurization, maintaining food at specific temperatures (typically 54-60degC) for extended periods to effectively eliminate pathogens while preserving texture and flavor. Unlike traditional high-temperature pasteurization-by-cooking, LTLT sous vide ensures uniform heat distribution and consistent microbial inactivation, enhancing both safety and quality in vacuum-sealed food.

Thermal Death Time (TDT) Curves

Thermal Death Time (TDT) curves illustrate the precise time-temperature combinations necessary to inactivate pathogens in food, making sous vide a controlled method that ensures safety with lower temperatures over extended periods. Unlike traditional pasteurization-by-cooking, sous vide leverages these TDT curves to optimize microbial kill while preserving food quality by preventing overcooking.

Log Reduction (LR) Standards

Sous vide cooking achieves precise Log Reduction (LR) standards by maintaining consistent low temperatures over extended periods, effectively reducing pathogens such as Listeria monocytogenes and Salmonella spp. Pasteurization-by-cooking typically relies on higher temperatures for shorter durations, often targeting lower LR thresholds, which can impact texture and moisture retention compared to sous vide methods.

Sous Vide Danger Zone

Sous vide cooking maintains food in a temperature range typically between 130degF and 140degF, which falls within the bacterial danger zone if not properly controlled, unlike traditional pasteurization that rapidly heats food to higher temperatures to kill pathogens. Precise temperature control and extended cooking times in sous vide are critical to ensuring food safety by effectively reducing harmful microorganisms without compromising texture and flavor.

z-Value in Sous Vide

Sous vide cooking relies on precise temperature control and extended time to achieve pathogen reduction, utilizing specific z-values to determine the thermal resistance of microorganisms and optimize food safety. Unlike traditional pasteurization-by-cooking methods, sous vide adjusts processing temperatures and durations based on exact z-values, ensuring effective microbial inactivation while preserving food quality.

Pasteurization Equivalent Temperature (PET)

Sous vide cooking achieves precise Pasteurization Equivalent Temperature (PET) control by maintaining consistent low temperatures over extended times, effectively eliminating pathogens while preserving food quality. In contrast, traditional pasteurization-by-cooking relies on higher temperatures for shorter durations, which can compromise texture and flavor despite achieving microbial safety.

Spore Inactivation Point

Sous vide cooking achieves precise temperature control, typically between 55degC and 65degC, which effectively pasteurizes food by inactivating most vegetative pathogens but does not reliably inactivate spores such as Clostridium botulinum. Pasteurization-by-cooking requires higher temperatures, often exceeding 70degC to 121degC under pressure, to reach the spore inactivation point necessary for safe long-term storage and prevention of spore germination and toxin formation.

Non-Proteolytic Clostridium Botulinum Limits

Sous vide cooking maintains precise low temperatures that effectively inhibit Non-Proteolytic Clostridium Botulinum spores, unlike traditional pasteurization-by-cooking which may require higher temperatures to ensure safety. Controlled sous vide conditions combined with proper time-temperature parameters reduce botulinum toxin risk while preserving food quality.

Core Temperature Validation

Sous vide cooking achieves food safety by precisely maintaining core temperatures, ensuring pathogens are effectively controlled through extended heat exposure at lower temperatures. In comparison, pasteurization-by-cooking relies on higher temperatures for shorter times, requiring rigorous core temperature validation to confirm that the entire product reaches the necessary heat to eliminate harmful microorganisms.

Sous vide vs pasteurization-by-cooking for food safety. Infographic

cookingdiff.com

cookingdiff.com