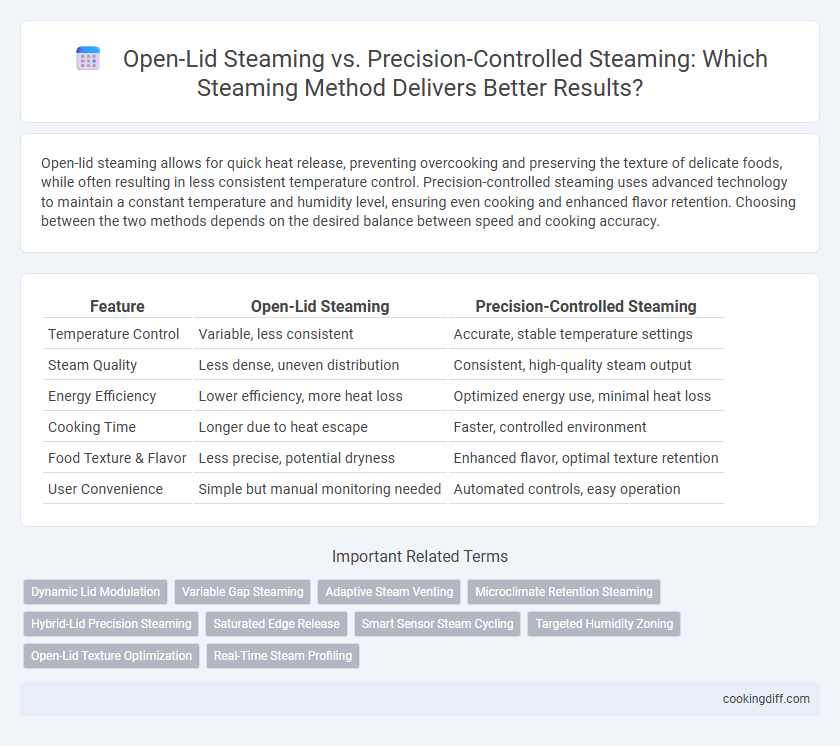

Open-lid steaming allows for quick heat release, preventing overcooking and preserving the texture of delicate foods, while often resulting in less consistent temperature control. Precision-controlled steaming uses advanced technology to maintain a constant temperature and humidity level, ensuring even cooking and enhanced flavor retention. Choosing between the two methods depends on the desired balance between speed and cooking accuracy.

Table of Comparison

| Feature | Open-Lid Steaming | Precision-Controlled Steaming |

|---|---|---|

| Temperature Control | Variable, less consistent | Accurate, stable temperature settings |

| Steam Quality | Less dense, uneven distribution | Consistent, high-quality steam output |

| Energy Efficiency | Lower efficiency, more heat loss | Optimized energy use, minimal heat loss |

| Cooking Time | Longer due to heat escape | Faster, controlled environment |

| Food Texture & Flavor | Less precise, potential dryness | Enhanced flavor, optimal texture retention |

| User Convenience | Simple but manual monitoring needed | Automated controls, easy operation |

Introduction to Steaming Methods

Open-lid steaming involves releasing steam with the lid removed, offering a traditional method for gently cooking food by direct exposure to steam. This technique facilitates quick moisture release but may lead to inconsistent temperature control during the cooking process.

Precision-controlled steaming utilizes advanced technology to regulate steam temperature and pressure for consistent and even cooking results. This method enhances nutrient retention and texture by maintaining optimal steaming conditions throughout the process.

What is Open-Lid Steaming?

Open-lid steaming is a traditional cooking method where the lid is removed to allow steam to escape, often resulting in less consistent heat and moisture retention. This technique is commonly used for quick steaming but may lead to uneven cooking compared to precision-controlled steaming.

- Heat Loss - Open-lid steaming causes heat and steam to escape, reducing cooking efficiency.

- Moisture Control - The method offers limited control over moisture retention, which can impact food texture.

- Cooking Speed - It generally cooks foods faster but with less precision in temperature regulation.

Overview of Precision-Controlled Steaming

| Precision-Controlled Steaming Overview |

| Precision-Controlled Steaming utilizes advanced temperature sensors and automated steam regulation to maintain optimal heat for uniform cooking. This method enhances food texture and flavor consistency by preventing over-steaming or under-steaming. Precision control improves energy efficiency and reduces cooking time compared to traditional open-lid steaming techniques. |

Key Differences Between Open-Lid and Precision-Controlled Steaming

Open-lid steaming involves releasing steam by lifting the lid, offering quick access but causing inconsistent temperature control. Precision-controlled steaming maintains a sealed environment, ensuring stable steam temperature and uniform cooking results throughout the process.

Open-lid steaming is ideal for rapid adjustments and short cooking durations, while precision-controlled steaming excels in delicate recipes requiring exact humidity and heat levels. This method reduces energy waste and preserves the texture and flavor of steamed ingredients more effectively.

Impact on Food Texture and Flavor

Open-lid steaming allows moisture to escape, often resulting in softer textures but milder flavors due to reduced steam retention. Precision-controlled steaming maintains consistent temperature and humidity, enhancing the food's texture firmness and intensifying its natural flavors.

Open-lid steaming is suitable for delicate foods that benefit from gentle cooking but may compromise on flavor depth. Precision-controlled steaming ensures even heat distribution, which preserves nutritional content and boosts flavor concentration. This method is ideal for complex dishes requiring precise texture and rich taste profiles.

Control Over Cooking Time and Temperature

Open-Lid Steaming offers less precise control over cooking time and temperature, often resulting in uneven cooking. Precision-Controlled Steaming uses digital settings to maintain exact temperatures and timing for optimal results.

- Open-Lid Steaming - Heat escapes continuously, causing fluctuations in temperature and requiring manual timing adjustments.

- Precision-Controlled Steaming - Advanced sensors and timers ensure consistent heat delivery and optimal cooking duration.

- Cooking Outcome - Precision-controlled methods produce uniformly cooked food with better texture and nutrient retention.

Energy Efficiency Comparison

Open-lid steaming results in higher energy consumption due to constant heat loss and evaporation, reducing overall efficiency. Precision-controlled steaming systems maintain optimal temperature and pressure, minimizing energy waste by sealing in steam and adjusting power output automatically. Studies show precision-controlled steaming can reduce energy use by up to 30% compared to traditional open-lid methods, highlighting its environmental and cost-saving benefits.

Suitability for Different Ingredients

Open-lid steaming offers flexibility for a variety of ingredients, allowing for easy adjustments in cooking time and moisture levels, making it ideal for vegetables and delicate foods that require less precise heat. Precision-controlled steaming provides consistent temperature and humidity, ensuring uniform cooking ideal for sensitive ingredients like seafood and dumplings that demand exact conditions. The choice between these methods depends on the ingredient's texture and cooking requirements, with precision control favored for complex recipes and open-lid suited for quick, adaptable steaming tasks.

Pros and Cons of Each Steaming Approach

Open-lid steaming allows easy access and quick monitoring but risks heat loss and inconsistent steam distribution. Precision-controlled steaming offers consistent temperature regulation and efficient steam usage but requires more advanced equipment and setup.

- Open-lid steaming - provides flexibility in cooking but can lead to unevenly cooked food due to steam escaping.

- Precision-controlled steaming - ensures evenly cooked dishes by maintaining constant steam levels for optimal texture.

- Equipment complexity - Open-lid steaming uses simple pots, while precision steaming demands specialized, often costly machinery.

Choosing between these methods depends on balancing convenience with cooking consistency and equipment availability.

Related Important Terms

Dynamic Lid Modulation

Open-Lid Steaming enables rapid heat dissipation by lifting the lid slightly, preventing overcooking but risking moisture loss, while Precision-Controlled Steaming uses dynamic lid modulation to maintain optimal steam pressure and temperature, ensuring consistent texture and nutrient retention. Dynamic Lid Modulation adjusts steam flow in real-time, balancing internal humidity and preventing condensation buildup for superior cooking accuracy.

Variable Gap Steaming

Variable Gap Steaming offers enhanced precision by adjusting the distance between the lid and the steaming surface, allowing for optimized heat and moisture control compared to traditional open-lid methods. This technique minimizes temperature fluctuations and ensures uniform cooking, improving texture and flavor retention in steamed foods.

Adaptive Steam Venting

Open-lid steaming relies on natural steam escape, which may cause inconsistent heat distribution and longer cooking times, while precision-controlled steaming utilizes adaptive steam venting to regulate moisture levels and temperature with exceptional accuracy. This approach optimizes texture and flavor retention by dynamically adjusting steam release, ensuring uniform cooking and enhanced food quality.

Microclimate Retention Steaming

Open-Lid Steaming allows for some heat and moisture to escape, resulting in less effective microclimate retention around the food, which can affect texture and flavor consistency. Precision-Controlled Steaming maintains a sealed environment with regulated temperature and humidity, enhancing microclimate retention to preserve moisture, nutrients, and achieve uniform cooking results.

Hybrid-Lid Precision Steaming

Hybrid-Lid Precision Steaming combines the advantages of open-lid steaming with precision-controlled temperature and humidity settings, ensuring optimal texture and nutrient retention in steamed foods. This method uses a specialized lid design to maintain consistent steam distribution, enhancing flavor infusion and reducing cooking time compared to traditional open-lid or standard precision steaming techniques.

Saturated Edge Release

Open-lid steaming enhances saturated edge release by allowing steam to escape, preventing over-saturation and maintaining precise moisture levels at the food's edges. Precision-controlled steaming ensures consistent saturated edge release by tightly regulating temperature and steam pressure, resulting in uniform texture and flavor without edge sogginess.

Smart Sensor Steam Cycling

Smart Sensor Steam Cycling enhances Precision-Controlled Steaming by automatically adjusting steam levels for optimal texture and flavor, unlike Open-Lid Steaming which relies on manual timing and inconsistent heat distribution. This technology ensures consistent cooking results, improved nutrient retention, and energy efficiency through precise steam modulation.

Targeted Humidity Zoning

Open-Lid Steaming allows for broad humidity dispersion but lacks precise control over moisture levels, resulting in inconsistent texture outcomes. Precision-Controlled Steaming employs targeted humidity zoning to deliver specific moisture concentrations, ensuring uniform cooking and optimized food texture.

Open-Lid Texture Optimization

Open-Lid Steaming enhances texture by allowing excess moisture to escape, producing a tender yet firm consistency ideal for delicate foods like vegetables. Unlike Precision-Controlled Steaming, which regulates temperature and timing for uniformity, Open-Lid Steaming focuses on natural evaporation to achieve optimal crispness and avoid sogginess.

Open-Lid Steaming vs Precision-Controlled Steaming for Steaming Infographic

cookingdiff.com

cookingdiff.com