Toasting enhances flavor by applying dry heat, causing sugars and proteins to break down and create rich, nutty aromas. Maillardization, a specific type of browning reaction between amino acids and reducing sugars, produces complex savory and caramelized flavors beyond simple toasting. Both processes deepen taste profiles, with Maillardization offering a more intense and varied flavor spectrum than basic toasting.

Table of Comparison

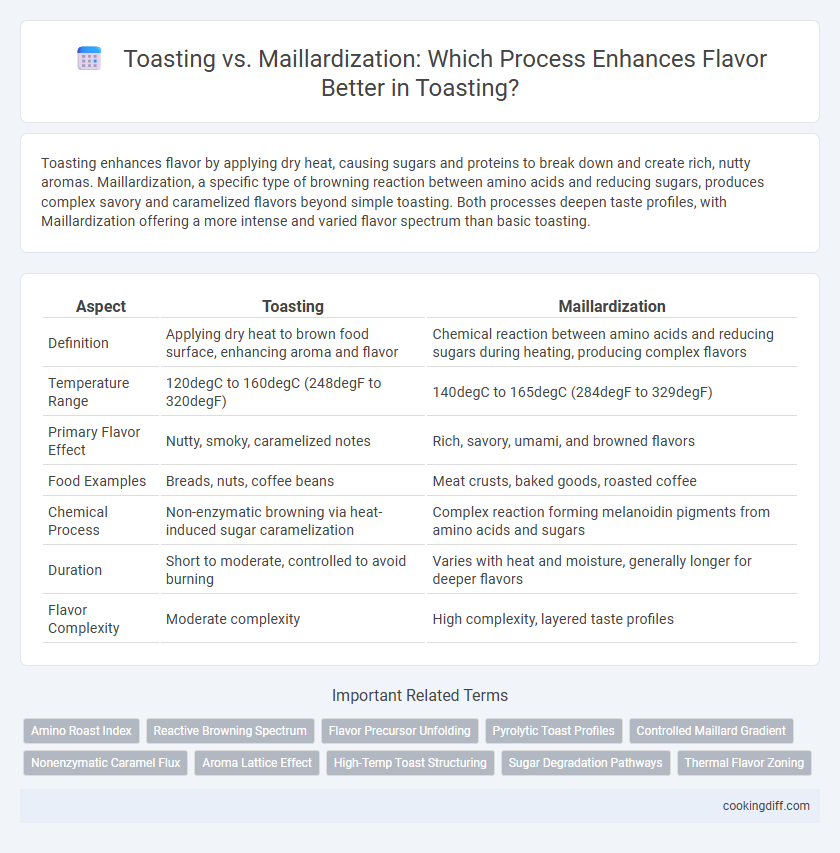

| Aspect | Toasting | Maillardization |

|---|---|---|

| Definition | Applying dry heat to brown food surface, enhancing aroma and flavor | Chemical reaction between amino acids and reducing sugars during heating, producing complex flavors |

| Temperature Range | 120degC to 160degC (248degF to 320degF) | 140degC to 165degC (284degF to 329degF) |

| Primary Flavor Effect | Nutty, smoky, caramelized notes | Rich, savory, umami, and browned flavors |

| Food Examples | Breads, nuts, coffee beans | Meat crusts, baked goods, roasted coffee |

| Chemical Process | Non-enzymatic browning via heat-induced sugar caramelization | Complex reaction forming melanoidin pigments from amino acids and sugars |

| Duration | Short to moderate, controlled to avoid burning | Varies with heat and moisture, generally longer for deeper flavors |

| Flavor Complexity | Moderate complexity | High complexity, layered taste profiles |

Understanding Toasting and Maillardization

Toasting involves the application of dry heat to food surfaces, resulting in caramelization that enhances sweetness and color, while Maillardization is a complex chemical reaction between amino acids and reducing sugars that produces rich, savory flavors and browned pigments. Understanding toasting is crucial for controlling the intensity of caramel notes, whereas Maillardization contributes deeper, more nuanced flavor profiles and aroma compounds. Both processes are essential in cooking techniques like baking and roasting, where balanced heat application optimizes taste and texture development.

Science Behind Toasting: What Happens at Bread’s Surface

Toasting initiates a complex series of chemical reactions at the bread's surface, primarily involving the Maillard reaction and caramelization. These processes break down sugars and amino acids, producing a rich array of flavor compounds and a distinct browned color.

The Maillard reaction specifically contributes to the nutty, savory notes by forming melanoidins through amino acid and reducing sugar interactions. Meanwhile, caramelization deepens sweetness as sugar molecules decompose at higher temperatures, creating a multifaceted toasted flavor profile.

The Maillard Reaction: A Deeper Dive into Flavor Chemistry

The Maillard reaction is a complex chemical process that occurs between amino acids and reducing sugars when food is heated, producing distinctive flavors and aromas that are richer and more varied than simple toasting. This reaction typically begins at temperatures above 140degC (284degF) and is fundamental in creating the brown crust on grilled meats, toasted bread, and roasted coffee, contributing to their characteristic savory and umami notes.

Toasting primarily involves caramelization, where heat breaks down sugars to develop sweetness and a mild toasted flavor, but it lacks the depth and molecular complexity achieved through Maillardization. Understanding the Maillard reaction offers insight into how heat transforms food at a molecular level, enhancing flavor profiles beyond what toasting alone can achieve.

Key Differences Between Toasting and Maillardization

Toasting involves dry heat applied to food, primarily browning the surface and enhancing flavor through caramelization of sugars, while Maillardization is a chemical reaction between amino acids and reducing sugars that produces complex flavor compounds and browning. Both processes contribute to flavor development but differ in their underlying chemical mechanisms and results.

- Heat Source - Toasting uses direct dry heat, whereas Maillardization occurs through heat-induced chemical reactions between proteins and sugars.

- Flavor Complexity - Maillardization generates more complex, savory flavors compared to the sweeter, nuttier notes from toasting.

- Temperature Range - Toasting typically occurs at higher temperatures (above 150degC) that cause surface browning, while Maillard reactions start around 140degC and increase with heat.

How Toasting Enhances Flavor and Texture

Toasting enhances flavor by applying dry heat, which triggers caramelization of sugars, producing sweet and nutty notes that deepen food's taste profile. This process also dries the surface, creating a crisp texture that contrasts with softer interiors.

Unlike Maillardization, which involves complex reactions between amino acids and reducing sugars resulting in browned, savory flavors, toasting primarily emphasizes caramelization-driven sweetness. Toasting intensifies aroma and flavor without requiring moisture or proteins, making it ideal for bread, nuts, and spices. The technique also alters texture by forming a crunchy exterior, enhancing mouthfeel and overall eating experience.

Maillardization’s Role in Complex Flavor Development

Maillardization plays a crucial role in developing complex flavors during toasting by triggering chemical reactions between amino acids and reducing sugars. This process creates a rich array of flavor compounds that go beyond the simpler caramel-like notes produced by basic toasting.

- Maillard Reaction - Initiates browning and flavor complexity by forming melanoidins through interactions between proteins and sugars.

- Flavor Development - Generates diverse savory, roasted, and nutty aromas enhancing the sensory profile of toasted foods.

- Comparison to Toasting - Unlike simple toasting, Maillardization contributes depth and sophistication to flavor rather than just surface browning.

Factors Affecting Toasting and Maillardization in Cooking

| Factor | Toasting | Maillardization |

|---|---|---|

| Temperature | Typically occurs at 120-160degC, promoting surface drying and browning. | Requires higher temperatures, usually between 140-165degC, to trigger reactions between amino acids and reducing sugars. |

| Moisture Content | Lower moisture enhances crispiness and caramelization of sugars during toasting. | Moderate moisture is necessary as Maillard reactions proceed faster with available water, but excess moisture inhibits browning. |

| Time | Shorter duration to prevent burning, optimized for flavor depth and texture. | Longer exposure favors complex flavor and color development through browning reactions. |

| pH Level | Has minimal direct effect on toasting but influences overall flavor perception. | Higher pH enhances Maillard reaction rates, intensifying browning and flavor complexity. |

| Substrate Composition | High carbohydrate content supports caramelization during toasting. | Presence of amino acids and reducing sugars are crucial for Maillard reaction progression. |

Comparing Culinary Results: Toasted vs Maillardized Foods

Toasting enhances flavor by applying dry heat that caramelizes surface sugars, producing a nutty and slightly sweet profile ideal for bread and nuts. Maillardization involves a complex chemical reaction between amino acids and reducing sugars at higher temperatures, generating rich, savory, and browned flavors in meats and roasted coffee. Comparing culinary results, toasting yields crisp textures with subtle caramel notes, while Maillardized foods develop deeper umami flavors and complex browning essential for gourmet dishes.

Practical Tips for Home Cooks: Maximizing Flavor with Each Technique

Toasting enhances food flavor by gently browning ingredients and releasing their natural oils, while Maillardization creates complex savory notes through a chemical reaction between amino acids and reducing sugars. Both methods deepen taste profiles but require different temperature controls to avoid burning or underdevelopment.

- Use medium heat for toasting - Apply moderate heat to evenly brown without charring and maintain ingredient texture.

- Preheat pans for Maillardization - Ensure surfaces are hot enough to trigger the Maillard reaction quickly and create rich flavors.

- Monitor time closely - Adjust toasting and browning times to optimize flavor development based on ingredient moisture and thickness.

Implementing precise heat management and timing allows home cooks to maximize flavor through both toasting and Maillardization techniques.

Related Important Terms

Amino Roast Index

The Amino Roast Index quantifies flavor development by measuring Maillard reaction products during toasting, highlighting the balance between caramelization and amino acid interactions. Toasting enhances flavor complexity beyond simple browning by optimizing Maillardization, resulting in richer, more savory taste profiles.

Reactive Browning Spectrum

Toasting primarily engages the Maillard reaction within the reactive browning spectrum, where amino acids and reducing sugars interact to develop complex, savory flavors and browned colors. Unlike caramelization, which involves only sugars, toasting balances Maillardization and mild caramelization, enhancing flavor depth through protein-sugar reactions.

Flavor Precursor Unfolding

Toasting enhances flavor by promoting the unfolding of flavor precursors such as amino acids and sugars, creating unique aromatic compounds through controlled thermal degradation. Maillardization involves complex reactions between reducing sugars and amino acids at higher temperatures, generating a broader spectrum of flavor and browning compounds essential for depth and richness in food profiles.

Pyrolytic Toast Profiles

Pyrolytic toast profiles develop unique, intense flavors through thermal decomposition, differing from Maillardization's amino acid-sugar reactions by creating deeper, smoky, and caramelized notes. This distinction highlights toasting's ability to generate complex, bold flavor layers that enhance foods beyond the typically nutty and savory Maillard flavors.

Controlled Maillard Gradient

Toasting develops flavor primarily through caramelization and controlled Maillard gradients, which precisely regulate temperature and moisture to enhance complex, savory notes without burning. The controlled Maillard gradient allows for a gradual development of amino acid and sugar reactions, creating richer, more nuanced flavors compared to traditional Maillardization methods that often lack this level of precision.

Nonenzymatic Caramel Flux

Toasting enhances flavor through the Nonenzymatic Caramel Flux, intensifying sweetness and complexity without the protein reactions typical of Maillardization. Unlike Maillardization, which produces savory and umami notes via amino acid-sugar interactions, toasting primarily drives caramelization, yielding rich, nutty, and deep caramel flavors.

Aroma Lattice Effect

Toasting enhances flavor by promoting the Aroma Lattice Effect, which organizes volatile compounds into complex aromatic networks, distinct from the chemical transformations in Maillardization that mainly generate browning and savory notes. This lattice effect intensifies specific aroma profiles, creating a richer sensory experience compared to the broader flavor development in Maillard reactions.

High-Temp Toast Structuring

High-temp toasting enhances flavor by creating a complex crust through thermal decomposition and caramelization, producing distinct roasted notes and a crunchy texture. This process contrasts with Maillardization, which primarily forms flavor through amino acid-sugar reactions at lower temperatures, emphasizing savory and nutty aromas.

Sugar Degradation Pathways

Toasting primarily induces sugar degradation through caramelization, breaking down sugars at high temperatures and creating distinct sweet, nutty flavors. Maillardization involves sugar reacting with amino acids, producing complex savory and roasted notes via advanced glycation end products that differ from the pure sugar breakdown in caramelization.

Toasting vs Maillardization for flavor. Infographic

cookingdiff.com

cookingdiff.com