Blanching involves briefly boiling vegetables to inactivate enzymes and preserve color, texture, and nutrients, followed by immediate cooling, which slows down cooking and prevents further softening. Shock chilling rapidly cools blanched vegetables using ice water or cold air to quickly reduce temperature and inhibit microbial growth. While blanching primarily prepares vegetables for freezing by halting enzymatic activity, shock chilling focuses on rapid temperature reduction to maintain freshness and safety in post-blanching processing.

Table of Comparison

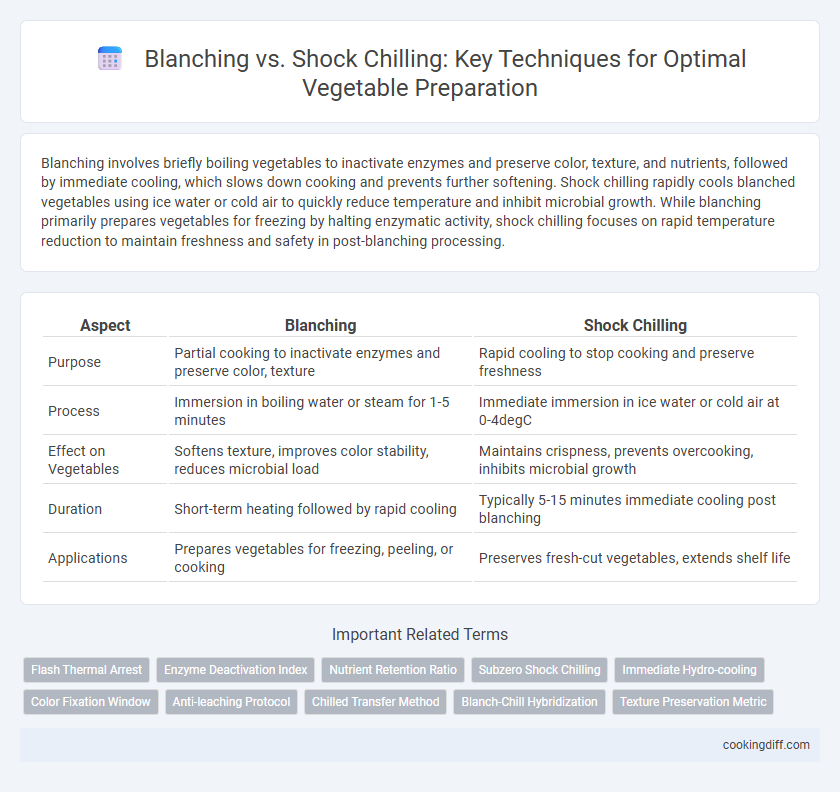

| Aspect | Blanching | Shock Chilling |

|---|---|---|

| Purpose | Partial cooking to inactivate enzymes and preserve color, texture | Rapid cooling to stop cooking and preserve freshness |

| Process | Immersion in boiling water or steam for 1-5 minutes | Immediate immersion in ice water or cold air at 0-4degC |

| Effect on Vegetables | Softens texture, improves color stability, reduces microbial load | Maintains crispness, prevents overcooking, inhibits microbial growth |

| Duration | Short-term heating followed by rapid cooling | Typically 5-15 minutes immediate cooling post blanching |

| Applications | Prepares vegetables for freezing, peeling, or cooking | Preserves fresh-cut vegetables, extends shelf life |

Introduction to Blanching and Shock Chilling

Blanching involves briefly boiling vegetables to halt enzyme activity and preserve color, flavor, and texture. Shock chilling rapidly cools blanch-treated vegetables in ice water to stop cooking and maintain quality.

- Blanching - A thermal process using hot water or steam to inactivate enzymes and prepare vegetables for freezing or further processing.

- Shock Chilling - Immediately immerses blanched vegetables in ice water to cool them rapidly and prevent overcooking.

- Purpose - Both techniques work together to enhance vegetable shelf life, texture, and nutritional retention during storage.

Combining blanching with shock chilling optimizes vegetable preparation by balancing cooking control and rapid temperature reduction.

What Is Blanching in Vegetable Preparation?

Blanching is a vegetable preparation technique involving briefly boiling vegetables before rapidly cooling them. This process helps preserve color, texture, and nutrients while halting enzyme activity that causes spoilage.

- Heat Treatment - Vegetables are immersed in boiling water or steam for a short time to inactivate enzymes.

- Rapid Cooling - After blanching, vegetables are quickly cooled in ice water to stop cooking and maintain quality.

- Preservation Benefits - Blanching extends shelf-life and prepares vegetables for freezing or further processing.

Understanding Shock Chilling: The Next Step After Blanching

Shock chilling rapidly cools blanched vegetables by immersing them in ice water or using cold air blasts, effectively halting the cooking process and preserving texture, color, and nutritional value. This method prevents overcooking and microbial growth, ensuring longer shelf life and enhanced quality compared to blanching alone. Incorporating shock chilling immediately after blanching optimizes vegetable preparation for freezing or fresh consumption.

Key Differences Between Blanching and Shock Chilling

Blanching involves briefly boiling vegetables to inactivate enzymes and preserve color, texture, and flavor, whereas shock chilling rapidly cools blanched vegetables in ice water to halt the cooking process. The key difference lies in blanching's role in preparation and enzyme deactivation, contrasted with shock chilling's purpose of maintaining quality and preventing overcooking. Blanching affects chemical changes while shock chilling controls temperature to retain crispness and nutritional value.

Benefits of Blanching for Vegetables

| Blanching preserves the vibrant color, flavor, and nutrient content of vegetables by briefly exposing them to boiling water or steam, which deactivates enzymes responsible for spoilage. This process enhances texture and extends shelf life by reducing microbial load, making vegetables safer for consumption. Compared to shock chilling, blanching offers superior enzyme inactivation, crucial for maintaining quality during freezing and long-term storage. |

Advantages of Shock Chilling After Blanching

Shock chilling after blanching rapidly reduces the temperature of vegetables, preserving their vibrant color, texture, and nutritional content more effectively than traditional cooling methods. This process minimizes enzyme activity, thereby extending shelf life and maintaining product quality.

The quick temperature drop achieved by shock chilling also reduces microbial growth, enhancing food safety and reducing spoilage. Additionally, it facilitates efficient workflow in commercial kitchens by allowing faster cooling and storage readiness.

Impact on Color, Flavor, and Nutrition

Blanching preserves the vibrant color of vegetables by inactivating enzymes that cause browning and texture degradation during storage or cooking. This process maintains the bright green in leafy vegetables and the crispness of root vegetables, enhancing visual appeal.

Shock chilling rapidly cools blanched vegetables, locking in color and slowing enzymatic activity, which further preserves flavor and nutritional content. While blanching reduces vitamin C slightly, shock chilling minimizes nutrient loss by preventing prolonged heat exposure.

How to Properly Blanch and Shock Chill Vegetables

Proper blanching involves immersing vegetables in boiling water for a specific time to halt enzyme activity and preserve quality. Shock chilling immediately follows by plunging the vegetables into ice water to stop the cooking process and maintain texture.

- Boil Duration - Vegetables should be boiled for 1 to 5 minutes depending on their type and size to ensure enzymes are deactivated without overcooking.

- Ice Water Bath - After boiling, vegetables must be submerged in ice water for an equal or longer time to cool rapidly and retain crispness.

- Drain and Dry - Proper draining and drying post shock chilling prevent excess water retention that can affect texture and shelf life.

Common Mistakes to Avoid in Blanching and Shock Chilling

A common mistake in blanching vegetables is overcooking, which leads to nutrient loss and texture degradation. In shock chilling, failing to immerse produce immediately in ice water can result in continued cooking and reduced crispness.

In blanching, inconsistent water temperature compromises enzyme inactivation, affecting shelf life and color retention. During shock chilling, neglecting to use sufficient ice or cold water volume causes inadequate cooling, allowing microbial growth. Avoiding these errors ensures optimal vegetable preparation and preservation.

Related Important Terms

Flash Thermal Arrest

Flash Thermal Arrest during blanching rapidly halts enzymatic activity by quickly reducing the temperature of vegetables, preserving texture and nutritional value more effectively than shock chilling. In contrast, shock chilling primarily focuses on rapid cooling to inhibit microbial growth but may not optimally control enzyme-induced quality degradation.

Enzyme Deactivation Index

Blanching achieves a higher Enzyme Deactivation Index by rapidly inactivating enzymes responsible for spoilage, preserving vegetable quality and shelf life more effectively than shock chilling. Shock chilling primarily halts cooking processes but does not significantly reduce enzymatic activity, making blanching the preferred method for enzyme deactivation in vegetable preparation.

Nutrient Retention Ratio

Blanching often results in a nutrient retention ratio of approximately 70-80% for water-soluble vitamins like vitamin C, while shock chilling preserves these nutrients more effectively with retention ratios reaching up to 90-95%. The reduced thermal exposure during shock chilling limits nutrient degradation, making it a superior method for maintaining the nutritional quality of vegetables post-cooking.

Subzero Shock Chilling

Subzero shock chilling rapidly reduces vegetable temperature below freezing point, preserving texture and nutrient content more effectively than traditional blanching methods. This technique minimizes enzymatic activity and microbial growth, extending shelf life while maintaining fresh-like quality.

Immediate Hydro-cooling

Blanching involves briefly heating vegetables in boiling water or steam to inactivate enzymes and preserve color, texture, and nutritional value, while shock chilling or immediate hydro-cooling rapidly lowers the temperature using cold water or ice to halt the cooking process and prevent microbial growth. Immediate hydro-cooling after blanching enhances vegetable quality by quickly stabilizing temperature, reducing thermal damage, and extending shelf life, making it essential in commercial vegetable processing.

Color Fixation Window

Blanching rapidly inactivates enzymes in vegetables, extending the color fixation window by preventing enzymatic browning and preserving vibrant hues. Shock chilling complements blanching by quickly reducing vegetable temperature, locking in color stability within the optimal fixation period.

Anti-leaching Protocol

Blanching uses hot water or steam to inactivate enzymes in vegetables, minimizing nutrient loss while maintaining texture, whereas shock chilling rapidly cools the product to halt cooking and reduce microbial growth. An effective anti-leaching protocol integrates controlled blanching time and temperature with immediate shock chilling to preserve water-soluble vitamins and prevent nutrient leaching.

Chilled Transfer Method

Blanching involves briefly cooking vegetables in boiling water or steam to inactivate enzymes, while the chilled transfer method of shock chilling rapidly reduces the temperature of blanched vegetables to preserve texture, color, and nutritional quality. This quick cooling process minimizes microbial growth and enzymatic activity, enhancing shelf life and maintaining the vegetable's crispness before further processing or storage.

Blanch-Chill Hybridization

Blanch-chill hybridization combines the benefits of blanching, which deactivates enzymes and preserves color, flavor, and texture, with shock chilling that rapidly reduces temperature to inhibit microbial growth and extend shelf life. This method optimizes vegetable preparation by enhancing food safety and quality while maintaining nutritional value and reducing processing time.

Blanching vs Shock Chilling for vegetable preparation. Infographic

cookingdiff.com

cookingdiff.com