Using a standard stove pot for blanching pet food ingredients provides reliable heat but often results in uneven cooking due to inconsistent temperature distribution. An induction blanch pan delivers rapid, precise heating with even temperature control, enhancing nutrient retention and texture quality in pet food. Induction technology increases energy efficiency, reduces blanching time, and ensures optimal results for maintaining pet food freshness and safety.

Table of Comparison

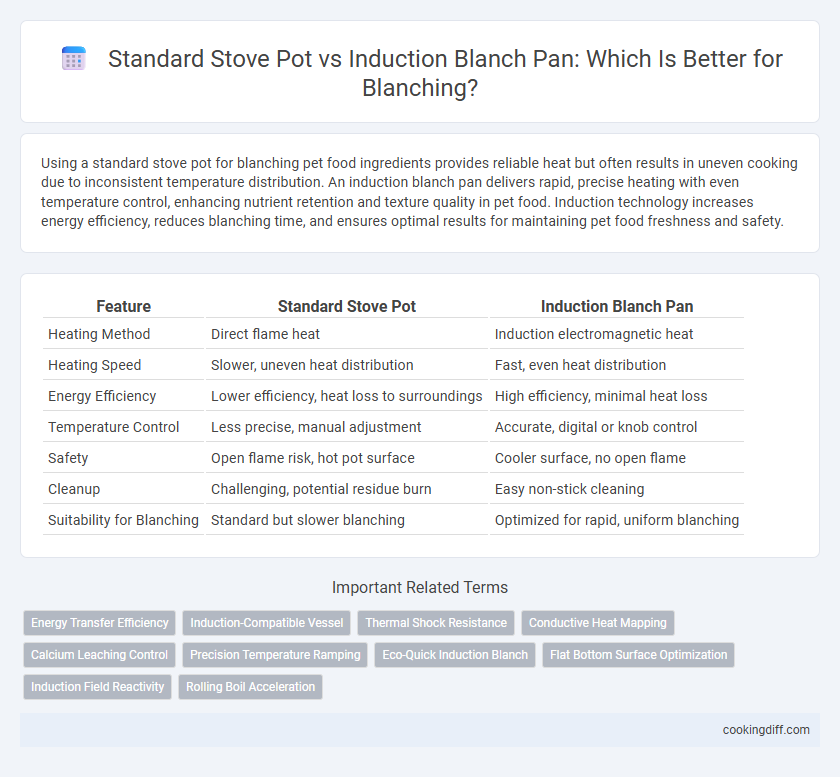

| Feature | Standard Stove Pot | Induction Blanch Pan |

|---|---|---|

| Heating Method | Direct flame heat | Induction electromagnetic heat |

| Heating Speed | Slower, uneven heat distribution | Fast, even heat distribution |

| Energy Efficiency | Lower efficiency, heat loss to surroundings | High efficiency, minimal heat loss |

| Temperature Control | Less precise, manual adjustment | Accurate, digital or knob control |

| Safety | Open flame risk, hot pot surface | Cooler surface, no open flame |

| Cleanup | Challenging, potential residue burn | Easy non-stick cleaning |

| Suitability for Blanching | Standard but slower blanching | Optimized for rapid, uniform blanching |

Introduction to Blanching: Basic Principles

Blanching involves briefly boiling vegetables to halt enzyme activity, preserving color, texture, and nutritional value. Standard stove pots rely on direct heat transfer, often resulting in uneven temperature control during blanching. Induction blanch pans provide precise, consistent heat through electromagnetic energy, enhancing efficiency and food quality in blanching processes.

Standard Stove Pot: How It Works for Blanching

Standard stove pots utilize direct heat transfer from a gas or electric burner to rapidly increase water temperature for blanching. This method allows precise control over water boil times, essential for preserving vegetable texture and color.

- Direct heat application - Heat transfers from the burner directly to the pot, heating water efficiently for blanching.

- Temperature control - Users can manually adjust flame or heat settings to maintain consistent boiling temperature.

- Versatile design - Compatible with various pot sizes, it supports blanching different vegetable quantities effectively.

Standard stove pots offer reliable, time-tested performance ideal for household blanching tasks requiring easy temperature adjustments.

Induction Blanch Pan: Technology and Use

The Induction Blanch Pan utilizes electromagnetic technology to heat food quickly and evenly, reducing blanching time compared to standard stove pots. Its precise temperature control prevents overcooking, preserving the texture and nutrients of vegetables. Energy efficiency is enhanced as the pan heats directly, minimizing heat loss typical in conventional stove pots.

Heating Efficiency: Stove Pot vs Induction Pan

Standard stove pots rely on gas or electric burners, which transfer heat through conduction and often result in uneven heating and longer blanching times. Induction blanch pans use electromagnetic fields to directly heat the pan, providing faster and more consistent heat distribution.

Induction technology improves energy efficiency by up to 90%, reducing wasted heat compared to the approximately 40-55% efficiency of traditional stove pots. This higher efficiency lowers cooking times and energy consumption, optimizing blanching performance for both home cooks and commercial kitchens.

Temperature Control and Precision

| Blanching Method | Temperature Control | Precision |

|---|---|---|

| Standard Stove Pot | Temperature varies with burner settings, often less consistent due to uneven heat distribution. | Limited precision; manual adjustments lead to fluctuating blanching temperatures. |

| Induction Blanch Pan | Offers precise temperature control through electromagnetic heating, rapidly adjusting to set temperatures. | High precision enables consistent blanching results and minimizes nutrient loss by maintaining exact heat levels. |

Energy Consumption Comparison

Standard stove pots typically consume more energy due to uneven heat distribution and longer heating times. Induction blanch pans offer precise temperature control, resulting in significant energy savings.

Induction blanch pans use electromagnetic energy directly on the pan, increasing efficiency by up to 90%, whereas standard stove pots rely on indirect heat transfer with about 40-55% efficiency. This difference reduces energy consumption by nearly half during blanching processes. The faster heat-up time of induction pans also minimizes wasted energy, making them a cost-effective choice for both residential and commercial kitchens.

Safety Considerations in Blanching

Standard stove pots used for blanching pose risks such as uneven heating and potential for boiling over, increasing the chance of burns or scalds. Induction blanch pans offer precise temperature control and rapid heating, enhancing safety by reducing the likelihood of accidental overheating.

Induction technology minimizes open flame exposure, lowering fire hazards compared to traditional gas stoves. The magnetic field used in induction blanch pans heats only the pan, reducing residual heat risks and making the blanching process safer for kitchen staff.

Blanching Results: Texture and Color Retention

Which method offers superior blanching results in terms of texture and color retention, a standard stove pot or an induction blanch pan? Induction blanch pans provide more consistent and rapid heat distribution, preserving the vibrant color and crisp texture of vegetables better than standard stove pots. This precise temperature control minimizes overcooking, ensuring optimal blanching quality for both commercial and home use.

Cost and Accessibility Factors

Standard stove pots are generally more affordable and widely accessible than specialized induction blanch pans, making them a popular choice for small-scale blanching tasks. Induction blanch pans, while more expensive upfront, offer energy efficiency and precise temperature control that can lead to long-term cost savings in commercial operations.

- Cost Efficiency - Standard stove pots have lower initial costs suitable for budget-conscious users.

- Energy Consumption - Induction blanch pans use less energy, reducing operating expenses over time.

- Accessibility - Stove pots are readily available in most households and markets globally.

Related Important Terms

Energy Transfer Efficiency

Induction blanch pans offer superior energy transfer efficiency compared to standard stove pots by directly heating the pan through electromagnetic induction, resulting in faster heat-up times and reduced energy loss. Standard stove pots rely on indirect heat transfer from the burner, causing energy dissipation and slower cooking processes during blanching.

Induction-Compatible Vessel

Induction blanch pans, designed with magnetic stainless steel or cast iron, ensure rapid and even heat distribution, significantly reducing blanching time compared to standard stove pots. Their induction-compatible vessels maximize energy efficiency and precise temperature control, enhancing vegetable texture and nutrient retention during the blanching process.

Thermal Shock Resistance

Induction blanch pans offer superior thermal shock resistance compared to standard stove pots, enabling rapid temperature changes without warping or damage. This durability ensures consistent blanching quality and extends the lifespan of cookware in high-heat, quick-cooling kitchen processes.

Conductive Heat Mapping

Induction blanch pans provide precise conductive heat mapping due to their magnetic induction technology, ensuring even heat distribution across the pan surface and reducing hot spots during blanching. Standard stove pots rely on traditional gas or electric heating elements which often result in uneven heat transfer and less consistent blanching outcomes.

Calcium Leaching Control

Induction blanch pans offer superior heat control compared to standard stove pots, minimizing calcium leaching during blanching by maintaining consistent temperatures and reducing overheating. Precise temperature regulation in induction blanch pans helps preserve vegetable calcium content, enhancing nutritional retention and overall food quality.

Precision Temperature Ramping

Induction blanch pans offer precise temperature ramping with rapid, controlled heat adjustments that maintain consistent blanching temperatures, essential for preserving food texture and nutrients. Standard stove pots lack this precision, often causing temperature fluctuations that can lead to uneven blanching and reduced product quality.

Eco-Quick Induction Blanch

The Eco-Quick Induction Blanch pan significantly reduces blanching time and energy consumption compared to a standard stove pot, thanks to its rapid heat transfer and precise temperature control. This induction blanch pan enhances food quality by maintaining nutrients and color integrity while improving kitchen efficiency and sustainability.

Flat Bottom Surface Optimization

A flat bottom surface on induction blanch pans ensures even heat distribution and consistent blanching results, minimizing hot spots commonly found in standard stove pots. This optimization enhances cooking efficiency by reducing blanching time and preserving vegetable texture and color.

Induction Field Reactivity

Induction blanch pans offer superior heat distribution and precise temperature control due to their magnetic field reactivity, significantly reducing blanching time compared to standard stove pots. This enhanced efficiency improves nutrient retention and texture in blanched vegetables by maintaining consistent high temperatures without overheating.

Standard Stove Pot vs Induction Blanch Pan for blanching. Infographic

cookingdiff.com

cookingdiff.com