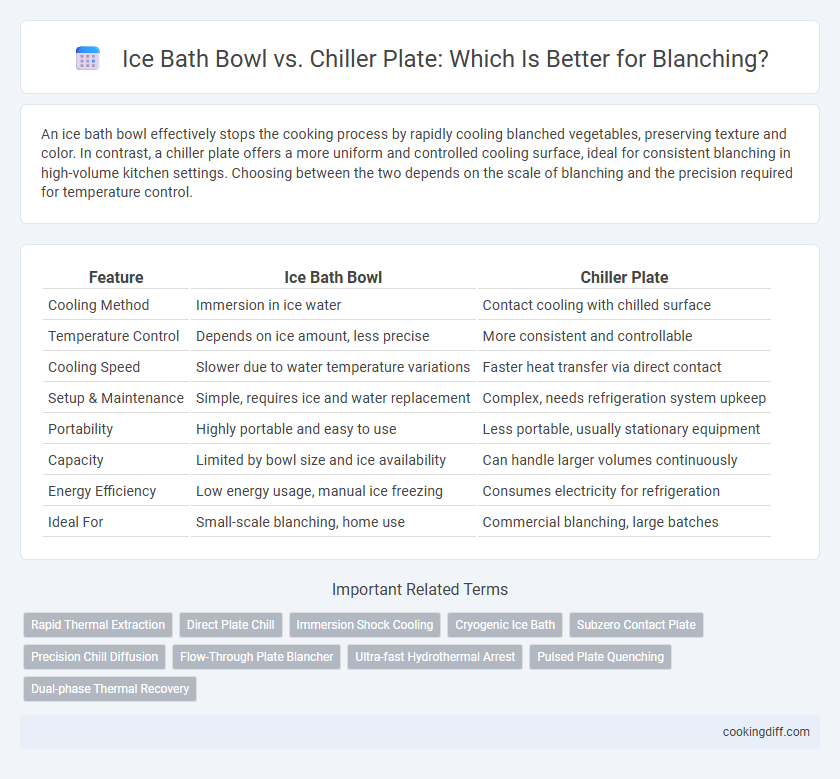

An ice bath bowl effectively stops the cooking process by rapidly cooling blanched vegetables, preserving texture and color. In contrast, a chiller plate offers a more uniform and controlled cooling surface, ideal for consistent blanching in high-volume kitchen settings. Choosing between the two depends on the scale of blanching and the precision required for temperature control.

Table of Comparison

| Feature | Ice Bath Bowl | Chiller Plate |

|---|---|---|

| Cooling Method | Immersion in ice water | Contact cooling with chilled surface |

| Temperature Control | Depends on ice amount, less precise | More consistent and controllable |

| Cooling Speed | Slower due to water temperature variations | Faster heat transfer via direct contact |

| Setup & Maintenance | Simple, requires ice and water replacement | Complex, needs refrigeration system upkeep |

| Portability | Highly portable and easy to use | Less portable, usually stationary equipment |

| Capacity | Limited by bowl size and ice availability | Can handle larger volumes continuously |

| Energy Efficiency | Low energy usage, manual ice freezing | Consumes electricity for refrigeration |

| Ideal For | Small-scale blanching, home use | Commercial blanching, large batches |

Introduction to Blanching: Why Cooling Matters

Blanching is a critical process in food preparation that involves briefly boiling vegetables followed by rapid cooling to halt the cooking process. Effective cooling prevents overcooking, preserves texture, color, and nutritional value.

An ice bath bowl offers a simple and cost-effective method for cooling blanched foods by immersing them in cold water with ice. A chiller plate provides faster, more controlled cooling and is ideal for high-volume or commercial blanching operations.

Ice Bath Bowl: Traditional Cooling Method Explained

The ice bath bowl is a traditional cooling method used in blanching that rapidly stops the cooking process by immersing vegetables in cold water mixed with ice. This technique helps maintain the vegetables' color, texture, and nutritional value by quickly reducing their temperature.

Ice bath bowls are favored for their simplicity, affordability, and effectiveness in small-scale or home blanching settings. Unlike chiller plates, they do not require electricity and can accommodate varying quantities of produce, making them a flexible cooling option.

Chiller Plate Overview: Modern Blanching Innovation

The chiller plate offers precise temperature control and rapid cooling, enhancing the blanching process efficiency compared to traditional ice bath bowls. Its stainless steel construction ensures durability and hygiene in commercial food processing.

Modern blanching with chiller plates reduces water usage and minimizes nutrient loss in vegetables. The uniform cooling surface accelerates heat transfer, resulting in consistent texture and color retention. This innovation also streamlines workflow by eliminating the need for large volumes of ice water, promoting sustainability in food production.

Speed of Cooling: Ice Bath Bowl vs Chiller Plate

The speed of cooling significantly impacts the effectiveness of blanching by quickly halting the cooking process. Ice bath bowls rely on thermal mass and surface contact, whereas chiller plates utilize direct cooling surfaces for faster heat extraction.

- Ice Bath Bowl Cooling Rate - Slower due to limited temperature differential and less efficient heat transfer through water convection.

- Chiller Plate Cooling Efficiency - Faster cooling achieved by direct conduction between food and a refrigerated metal plate.

- Impact on Texture and Color - Rapid cooling with chiller plates better preserves texture and vibrant color by immediately stopping enzymatic activity.

Chiller plates offer a more rapid and controlled cooling environment compared to ice bath bowls, enhancing blanching quality.

Temperature Control and Consistency Comparison

Ice bath bowls provide rapid temperature reduction by immersing blanched vegetables in cold water, which can lead to inconsistent cooling due to varying ice melt rates and water temperature fluctuations. Chiller plates offer precise temperature control with consistent surface cooling, ensuring uniform blanching results by maintaining stable thermal contact. The choice between the two significantly impacts blanching quality, with chiller plates delivering greater consistency for large-scale or industrial applications.

Impact on Food Texture and Color Preservation

Using an ice bath bowl for blanching rapidly cools vegetables, effectively halting the cooking process and preserving vibrant color but may sometimes result in slightly waterlogged texture. Chiller plates offer more uniform cooling and better texture retention by limiting water contact, thus maintaining the firmness and crispness of the food.

- Ice Bath Bowl Cooling - Quickly stops cooking and preserves bright colors but can cause slight moisture absorption affecting texture.

- Chiller Plate Cooling - Reduces water contact to maintain firmer, crisper texture and consistent color retention.

- Color Preservation - Both methods preserve color, though chiller plates minimize color leaching for cleaner presentation.

Water Usage and Environmental Considerations

Which method between ice bath bowls and chiller plates uses less water during blanching? Ice bath bowls require large volumes of water to maintain cold temperatures as water needs frequent replenishment to preserve effectiveness. Chiller plates use significantly less water by efficiently cooling vegetables through direct contact, reducing overall water consumption and environmental impact.

Space, Setup, and Convenience Factors

| Space | Ice bath bowls require minimal space and can fit in standard kitchen sinks, while chiller plates demand more counter area and often dedicated refrigeration units. |

| Setup | Ice bath bowls have straightforward setup with just ice and water needed, whereas chiller plates require electrical connections and pre-cooling, making installation more complex. |

| Convenience | Ice bath bowls offer quick and flexible blanching with easy cleanup, but chiller plates provide consistent temperature control ideal for precise blanching processes. |

Cost Analysis: Upfront and Operating Expenses

Ice bath bowls usually require lower upfront costs compared to chiller plates, making them more accessible for small-scale operations. However, their operating expenses tend to be higher due to continuous ice replenishment and labor intensity.

- Initial Investment - Ice bath bowls have minimal purchase costs, while chiller plates demand significant capital expenditure for equipment.

- Energy Consumption - Chiller plates use electricity consistently but are more energy-efficient compared to the repeated ice production needs of ice baths.

- Maintenance and Labor - Ice bath bowls incur higher ongoing labor and ice procurement costs, whereas chiller plates require scheduled maintenance but less manual input.

Related Important Terms

Rapid Thermal Extraction

Ice bath bowls provide rapid cooling by submerging blanched vegetables in cold water, effectively stopping enzymatic activity through immediate heat extraction. Chiller plates offer precise thermal extraction by conducting heat away quickly via direct contact, minimizing water use and enhancing energy efficiency in blanching processes.

Direct Plate Chill

Direct Plate Chill offers precise temperature control and rapid cooling during blanching by using chilled metal plates that transfer heat efficiently, reducing nutrient loss and texture damage compared to traditional ice bath bowls. This method enhances food safety and quality by minimizing water usage and eliminating cross-contamination risks commonly associated with ice baths.

Immersion Shock Cooling

Immersion shock cooling during blanching is more effective with an ice bath bowl because it rapidly lowers the temperature of vegetables, preserving texture and color. Chiller plates provide a slower cooling rate, which can lead to uneven temperature reduction and reduced quality retention.

Cryogenic Ice Bath

Cryogenic ice baths provide rapid cooling during blanching by maintaining temperatures far below standard ice water, significantly preserving color, texture, and nutrients in vegetables. Unlike chiller plates, ice bath bowls offer greater surface area contact and faster heat removal, making cryogenic ice baths ideal for high-throughput blanching processes.

Subzero Contact Plate

A Subzero Contact Plate provides rapid and uniform cooling during blanching by directly transferring cold temperatures to vegetables, minimizing nutrient loss and preserving texture better than traditional ice bath bowls. Unlike ice bath bowls, which rely on immersion and often cause uneven cooling and water retention, the chiller plate enhances efficiency by maintaining consistent subzero contact and expediting the cooling process.

Precision Chill Diffusion

Ice bath bowls provide rapid cooling through direct ice and water contact, but chiller plates offer superior precision chill diffusion by maintaining consistent, evenly distributed cold temperatures for optimal blanching results. Precision chill diffusion in chiller plates minimizes temperature fluctuations, enhancing texture retention and color vibrancy in blanched vegetables.

Flow-Through Plate Blancher

Flow-through plate blanchers utilize chiller plates to rapidly cool vegetables by circulating cold water through sealed channels, ensuring uniform heat transfer and minimizing nutrient loss. Unlike ice bath bowls, these systems offer precise temperature control and reduced water usage, resulting in higher efficiency and improved product quality during the blanching process.

Ultra-fast Hydrothermal Arrest

Ice bath bowls provide rapid cooling by submerging blanched vegetables in cold water, effectively halting enzymatic activity through ultra-fast hydrothermal arrest. In contrast, chiller plates offer immediate surface cooling with consistent temperature control, minimizing water usage and preserving texture during the blanching process.

Pulsed Plate Quenching

Pulsed plate quenching using a chiller plate provides rapid, uniform cooling by efficiently transferring cold temperatures directly to blanched vegetables, preserving texture and color more effectively than traditional ice bath bowls, which can cause uneven cooling and water absorption. The chiller plate's advanced thermal regulation minimizes nutrient loss and microbial growth, making it a superior choice for high-volume blanching processes requiring precise temperature control.

Ice bath bowl vs Chiller plate for blanching. Infographic

cookingdiff.com

cookingdiff.com