Candying preserves fruit by slowly infusing sugar over time, resulting in a dense, sweet texture ideal for traditional desserts. Vacuum impregnation accelerates this process by using pressure changes to infuse liquids rapidly, enhancing flavor penetration without compromising fruit structure. While candying offers classic sweetness and chew, vacuum impregnation provides precise control and efficiency for modern fruit dessert applications.

Table of Comparison

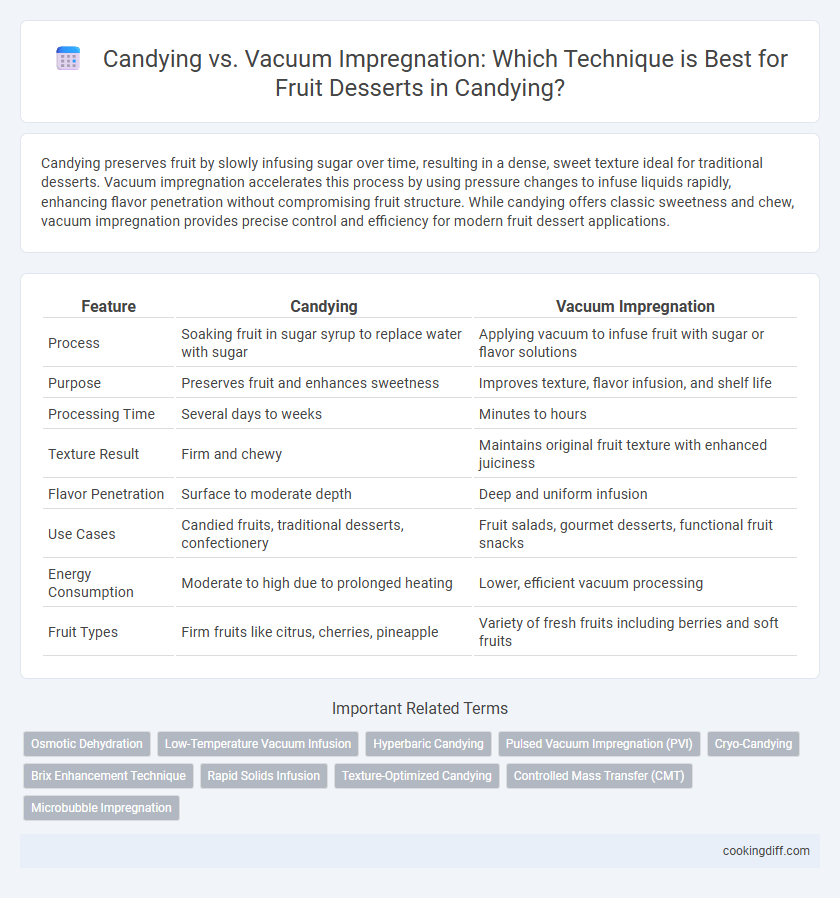

| Feature | Candying | Vacuum Impregnation |

|---|---|---|

| Process | Soaking fruit in sugar syrup to replace water with sugar | Applying vacuum to infuse fruit with sugar or flavor solutions |

| Purpose | Preserves fruit and enhances sweetness | Improves texture, flavor infusion, and shelf life |

| Processing Time | Several days to weeks | Minutes to hours |

| Texture Result | Firm and chewy | Maintains original fruit texture with enhanced juiciness |

| Flavor Penetration | Surface to moderate depth | Deep and uniform infusion |

| Use Cases | Candied fruits, traditional desserts, confectionery | Fruit salads, gourmet desserts, functional fruit snacks |

| Energy Consumption | Moderate to high due to prolonged heating | Lower, efficient vacuum processing |

| Fruit Types | Firm fruits like citrus, cherries, pineapple | Variety of fresh fruits including berries and soft fruits |

Introduction to Fruit Dessert Techniques

What distinguishes candying from vacuum impregnation in fruit dessert preparation? Candying involves soaking fruit in sugar syrup to preserve texture and enhance sweetness, while vacuum impregnation infuses flavors and liquids deeper into fruit under reduced pressure. These techniques offer unique benefits for texture and flavor, making them essential in modern fruit dessert creation.

Overview of Candying Process

Candied fruit is produced by soaking fruit in sugar syrup, allowing the sugar to replace the water content, which preserves the fruit while imparting a sweet flavor and chewy texture. This traditional candying process involves repeated cycles of immersion and drying to ensure thorough sugar penetration and extended shelf life.

The candying technique contrasts with vacuum impregnation, where pressure changes assist in infusing sugar solutions into fruit more rapidly and uniformly. Candying relies on osmotic dehydration over time, making it ideal for creating textured, naturally sweet fruit desserts without complex machinery.

What Is Vacuum Impregnation?

Vacuum impregnation is a food processing technique that removes air from the fruit's pores under vacuum and replaces it with a flavorful liquid, enhancing texture and taste. Unlike traditional candying, which relies on slow sugar absorption, vacuum impregnation allows for faster infusion of syrups or flavor solutions without overcooking. This method preserves the fruit's natural appearance and nutrients, making it ideal for creating high-quality fruit desserts with consistent sweetness and moisture.

Key Differences Between Candying and Vacuum Impregnation

Candying involves soaking fruit in a sugar syrup to preserve and sweeten it, creating a glossy, sweet exterior and firm texture. Vacuum impregnation, on the other hand, uses vacuum pressure to infuse liquids into fruit, enhancing flavor and texture without the prolonged cooking process.

The key differences between candying and vacuum impregnation include the duration and method of infusion; candying requires extended soaking and often heat, while vacuum impregnation is faster and uses pressure to ensure deeper liquid penetration. Candying results in a chewy, candied exterior with high sugar content, making it ideal for decorative fruit desserts and confections. Vacuum impregnation preserves the fruit's fresh texture and natural appearance, allowing for more controlled flavor enhancement and moisture retention in fruit-based desserts.

Flavor and Texture Outcomes

Candying enhances fruit desserts by infusing sweetness while preserving a chewy texture, whereas vacuum impregnation allows for precise flavor penetration with minimal texture alteration. Both techniques impact the final sensory profile, influencing consumer experience significantly.

- Candying intensifies sweetness - Sugar replaces moisture in the fruit, creating a dense, chewy consistency that highlights natural flavors.

- Vacuum impregnation maximizes flavor infusion - It forces flavorful solutions into the fruit's pores, achieving uniform taste without compromising firmness.

- Texture preservation - Candying often results in softer texture compared to vacuum impregnation, which maintains the original crispness of the fruit.

Ingredient Suitability: Which Fruits Work Best

Candying is ideal for dense fruits like cherries, figs, and citrus peels that can absorb sugar syrup slowly without losing structure. Vacuum impregnation suits porous fruits such as apples, pears, and berries, allowing rapid infusion of syrups or flavors deep into the tissue.

Candying preserves the original texture by gradually replacing water with sugar, making it suitable for tougher fruits. Vacuum impregnation enhances flavor penetration but may cause softer fruits to become mushy due to pressure changes.

Processing Time and Efficiency

Candying fruit requires extended processing times due to slow sugar absorption, making it less efficient for rapid production compared to vacuum impregnation. Vacuum impregnation significantly reduces processing time by using pressure differentials to infuse sugars and flavors quickly into fruit tissue.

- Candying is time-intensive - The traditional process can take several days to ensure complete sugar penetration and preservation.

- Vacuum impregnation enhances efficiency - It dramatically shortens the infusion period, often completing within hours instead of days.

- Processing time impacts production scale - Faster vacuum impregnation methods facilitate higher throughput in commercial fruit dessert manufacturing.

Nutritional Impact of Each Method

Candying fruit involves preserving it in sugar syrup, which significantly increases the fruit's sugar content and calorie density. Vacuum impregnation allows for controlled infusion of nutrients and flavors with minimal sugar addition, preserving more of the fruit's original vitamins and antioxidants. Compared to candying, vacuum impregnation better maintains the fruit's nutritional profile while enhancing texture and taste in fruit desserts.

Applications in Modern Fruit Desserts

Candying preserves fruit by osmotic dehydration in sugar syrup, enhancing flavor and texture, while vacuum impregnation introduces functional ingredients under reduced pressure to improve fruit quality and shelf life. Both techniques are widely used in modern fruit desserts for their distinct textural and taste modifications.

- Candying enhances sweetness and chewiness - It is ideal for decorative fruit toppings and rich-textured dessert components.

- Vacuum impregnation allows nutrient fortification - It is used to infuse vitamins, flavors, or colorants uniformly into fruit pieces.

- Vacuum impregnation shortens processing time - This method is more efficient for preserving fresh-like qualities in fruit-based desserts.

Choosing between candying and vacuum impregnation depends on the desired texture, flavor profile, and nutritional goals in fruit dessert innovation.

Related Important Terms

Osmotic Dehydration

Candying involves osmotic dehydration where sugar syrup draws out moisture from fruits, creating a concentrated, sweet texture ideal for fruit desserts. Vacuum impregnation enhances osmotic dehydration by applying reduced pressure, accelerating water removal and improving syrup uptake, resulting in a more evenly candied product with superior flavor and texture.

Low-Temperature Vacuum Infusion

Low-temperature vacuum infusion preserves fruit texture and nutritional content more effectively than traditional candying by infusing sugars and flavors under reduced pressure without heat. This method enhances fruit desserts' moisture retention and flavor intensity while minimizing thermal degradation and browning commonly associated with conventional candying processes.

Hyperbaric Candying

Hyperbaric candying leverages high-pressure conditions to infuse sugar solutions deeply into fruit tissues, preserving texture and enhancing flavor more effectively than traditional candying methods. Unlike vacuum impregnation, which uses low pressure to remove air and replace it with syrup, hyperbaric candying increases solute diffusion rates, resulting in superior sugar penetration and improved shelf life of fruit desserts.

Pulsed Vacuum Impregnation (PVI)

Pulsed Vacuum Impregnation (PVI) enhances fruit desserts by rapidly infusing syrups and flavors into fruit tissues under controlled vacuum pulses, significantly improving texture and taste compared to traditional candying. PVI offers superior retention of nutritional compounds and reduced processing time, making it an advanced alternative to conventional vacuum impregnation techniques.

Cryo-Candying

Cryo-Candying enhances fruit desserts by preserving natural flavors and textures through low-temperature infusion, offering superior nutrient retention compared to traditional candying and vacuum impregnation. Unlike vacuum impregnation, Cryo-Candying minimizes cellular damage, resulting in intensely flavored, visually appealing, and shelf-stable fruit products with reduced sugar absorption.

Brix Enhancement Technique

Candying enhances fruit desserts by immersing fruits in high-concentration sugar syrup, significantly increasing their Brix level to improve sweetness and preservation. Vacuum impregnation, on the other hand, infuses sugar solutions into fruit pores under reduced pressure, achieving uniform Brix enhancement while maintaining texture and natural flavor more effectively than traditional candying.

Rapid Solids Infusion

Candying involves soaking fruit in sugar syrup to achieve sweetness and preservation through osmotic diffusion, while vacuum impregnation rapidly infuses solids by removing air pockets under reduced pressure, enhancing penetration and texture uniformity in fruit desserts. Vacuum impregnation offers faster processing times and improved structural integrity, making it superior to traditional candying for rapid solids infusion in fruit desserts.

Texture-Optimized Candying

Texture-optimized candying enhances fruit desserts by preserving firmness and creating a tender yet slightly chewy bite, achieved through controlled sugar infusion and drying processes. Vacuum impregnation, while effective for rapid flavor incorporation, often leads to softer textures, making candying the preferred method for maintaining a desirable, structured mouthfeel in fruit-based confections.

Controlled Mass Transfer (CMT)

Candying involves controlled mass transfer (CMT) by gradually replacing fruit water content with sugar syrup, preserving texture and enhancing flavor; vacuum impregnation accelerates CMT by applying negative pressure to infuse solutions deeper and more uniformly. Both methods optimize sweetness and preservation but vacuum impregnation offers precise control over mass transfer rates, improving product consistency and reducing processing time.

Candying vs Vacuum impregnation for fruit desserts. Infographic

cookingdiff.com

cookingdiff.com