Traditional stoneware offers natural temperature regulation and breathability for pet fermenting, preserving authentic flavors through slow, consistent fermentation. Vacuum fermentation boxes provide precise control over oxygen levels and temperature, accelerating the process while minimizing the risk of contamination. Choosing between these methods depends on whether you prioritize traditional craftsmanship or modern efficiency in pet food fermentation.

Table of Comparison

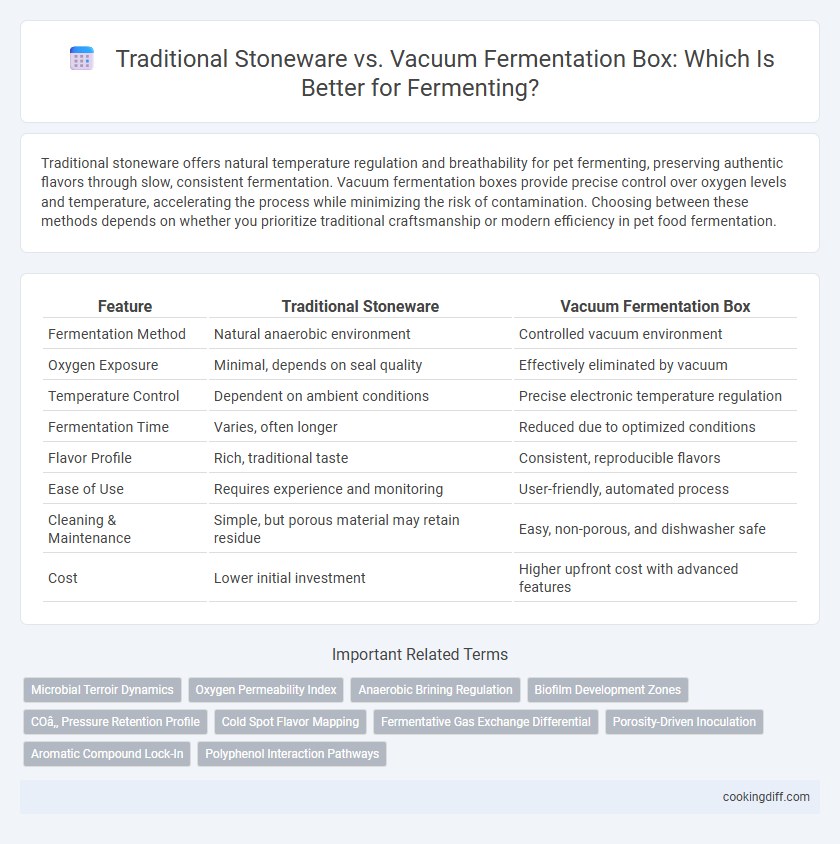

| Feature | Traditional Stoneware | Vacuum Fermentation Box |

|---|---|---|

| Fermentation Method | Natural anaerobic environment | Controlled vacuum environment |

| Oxygen Exposure | Minimal, depends on seal quality | Effectively eliminated by vacuum |

| Temperature Control | Dependent on ambient conditions | Precise electronic temperature regulation |

| Fermentation Time | Varies, often longer | Reduced due to optimized conditions |

| Flavor Profile | Rich, traditional taste | Consistent, reproducible flavors |

| Ease of Use | Requires experience and monitoring | User-friendly, automated process |

| Cleaning & Maintenance | Simple, but porous material may retain residue | Easy, non-porous, and dishwasher safe |

| Cost | Lower initial investment | Higher upfront cost with advanced features |

Introduction to Fermentation Methods

| Traditional stoneware crocks provide a natural, breathable environment ideal for fermenting vegetables, allowing gases to escape while protecting from contaminants. Vacuum fermentation boxes create a controlled, oxygen-free atmosphere that enhances anaerobic conditions and can speed up fermentation processes. Both methods offer distinct advantages depending on the desired fermentation style and flavor profile. |

Traditional Stoneware Fermentation: Overview

Traditional stoneware fermentation utilizes natural clay vessels that maintain consistent temperatures and allow for optimal airflow, enhancing the development of complex flavors in fermented foods. These vessels' porous nature facilitates the slow release of gases produced during fermentation, supporting beneficial microbial activity.

The weight and inert properties of stoneware provide a stable environment that minimizes contamination risks and preserves the authenticity of fermentation processes. This method has been favored for centuries in fermenting products like sauerkraut, kimchi, and pickles, ensuring rich textures and traditional taste profiles.

Vacuum Fermentation Box: Modern Innovation

The Vacuum Fermentation Box offers precise control over temperature and humidity, creating an ideal environment for consistent fermentation results. Unlike traditional stoneware, it eliminates exposure to oxygen, reducing the risk of contamination and spoilage.

Modern innovation in fermentation technology allows the Vacuum Fermentation Box to accelerate the fermentation process while enhancing flavor development. Its airtight design maintains optimal anaerobic conditions, crucial for fermenting foods such as kimchi, sauerkraut, and sourdough. This advanced method ensures higher quality and reproducibility compared to traditional stoneware vessels.

Material Properties and Impact on Fermentation

Traditional stoneware offers excellent thermal insulation and breathability, which helps maintain consistent fermentation temperatures and promotes natural gas exchange. In contrast, vacuum fermentation boxes provide airtight conditions with controlled pressure, accelerating fermentation by reducing oxygen exposure and enhancing flavor development.

- Material porosity - Stoneware's porous surface allows micro-oxygenation essential for developing complex fermentation profiles.

- Temperature stability - Stoneware retains heat evenly, preventing temperature fluctuations that can disrupt microbial activity.

- Airtight environment - Vacuum boxes create an oxygen-free environment, minimizing oxidation and mold growth during fermentation.

The choice between stoneware and vacuum boxes significantly influences fermentation dynamics, impacting flavor, texture, and microbial health.

Flavor Profiles: Stoneware vs Vacuum Box

Traditional stoneware fermentation enhances flavor complexity through slow, natural oxygen exposure, promoting richer umami and tangy notes. Vacuum fermentation boxes create a controlled anaerobic environment, intensifying sourness and preserving crisp textures by inhibiting unwanted microbial growth.

- Stoneware flavor complexity - Slow aerobic fermentation in stoneware allows diverse microbial activity, enriching depth and subtle nuances.

- Vacuum box sourness - Anaerobic conditions in vacuum boxes boost lactic acid production, resulting in pronounced tangy and sharp flavors.

- Texture preservation - Vacuum boxes maintain crispness by minimizing oxidation and moisture loss during fermentation.

Fermentation Control and Ease of Use

Traditional stoneware offers natural temperature regulation and moisture retention, aiding consistent fermentation, but requires careful monitoring to prevent spoilage. Vacuum fermentation boxes provide precise control over fermentation parameters such as temperature, humidity, and oxygen levels, enhancing consistency and safety. The vacuum box's user-friendly interface and airtight design simplify the fermentation process, reducing manual oversight compared to stoneware methods.

Cleaning and Maintenance Comparisons

Traditional stoneware requires thorough hand cleaning with warm water and mild detergent to avoid damaging its porous surface, which can retain odors and bacteria if not properly maintained. Vacuum fermentation boxes feature non-porous materials like food-grade plastic or stainless steel, allowing for easier sanitization and minimizing cross-contamination risks. Regular maintenance for vacuum boxes includes simply wiping down surfaces and occasionally replacing silicone seals, making them more convenient for frequent fermenting tasks.

Tradition and Cultural Heritage

Traditional stoneware has been used for centuries in fermenting processes, preserving cultural heritage and ancestral methods. Its porous nature allows for natural airflow, fostering authentic flavors and textures in fermented foods.

Vacuum fermentation boxes offer modern precision but lack the deep-rooted tradition embedded in stoneware vessels. Stoneware remains a symbol of cultural identity, connecting generations through time-honored fermentation craftsmanship.

Cost and Accessibility

Traditional stoneware is generally more affordable and widely accessible compared to vacuum fermentation boxes, making it a popular choice among home fermenters. Vacuum fermentation boxes often come at a higher cost and may require ordering from specialty retailers, limiting their availability for casual users.

- Cost-effectiveness of stoneware - Stoneware is typically lower in price due to common production methods and materials.

- Higher price of vacuum boxes - Vacuum fermentation boxes involve advanced technology and materials, increasing their purchase cost.

- Accessibility differences - Stoneware is found easily in kitchenware stores and online, whereas vacuum boxes are often niche products with limited distribution.

Related Important Terms

Microbial Terroir Dynamics

Traditional stoneware preserves microbial terroir dynamics by allowing natural airflow and maintaining stable humidity, enhancing the diversity and balance of native fermenting microbes. Vacuum fermentation boxes create a controlled anaerobic environment that can limit microbial diversity but promote specific metabolite production through selective pressure on fermenting strains.

Oxygen Permeability Index

Traditional stoneware offers a moderate oxygen permeability index, allowing controlled airflow that supports natural fermentation with balanced microbial activity. Vacuum fermentation boxes, with near-zero oxygen permeability, create anaerobic environments that accelerate fermentation by limiting oxygen exposure and reducing oxidation risks.

Anaerobic Brining Regulation

Traditional stoneware promotes natural anaerobic brining through its porous material that maintains steady moisture and temperature, supporting beneficial microbial activity during fermentation. Vacuum fermentation boxes enhance anaerobic conditions by actively removing oxygen, offering precise regulation of brine concentration and reducing the risk of spoilage bacteria growth.

Biofilm Development Zones

Traditional stoneware creates natural biofilm development zones due to its porous surface, promoting beneficial microbial growth essential for fermentation. Vacuum fermentation boxes limit oxygen exposure, resulting in more controlled but less diverse biofilm formation, which can affect the complexity and flavor profile of fermented products.

CO₂ Pressure Retention Profile

Traditional stoneware vessels exhibit natural porosity that allows gradual CO2 escape, resulting in lower pressure retention and slower fermentation processes. In contrast, vacuum fermentation boxes provide airtight environments that maintain high CO2 pressure, accelerating fermentation rates and enhancing flavor development by reducing oxidation.

Cold Spot Flavor Mapping

Traditional stoneware excels in cold spot flavor mapping by naturally maintaining stable, cool temperatures that promote even fermentation and complex flavor development. Vacuum fermentation boxes control environmental variables precisely but may limit the nuanced cold spot variations that enhance depth and character in fermented products.

Fermentative Gas Exchange Differential

Traditional stoneware relies on natural, porous materials that allow slow gas exchange during fermentation, maintaining oxygen levels conducive to beneficial microbial activity. In contrast, vacuum fermentation boxes create a low-oxygen environment by actively removing fermentative gases, accelerating anaerobic fermentation and enhancing flavor profiles through controlled gas exchange differentials.

Porosity-Driven Inoculation

Traditional stoneware offers natural porosity that facilitates microbial inoculation, enhancing fermentation complexity through gradual oxygen exchange and retention of beneficial bacteria. Vacuum fermentation boxes, by contrast, limit oxygen exposure to create anaerobic conditions, reducing porosity-driven inoculation and favoring controlled, consistent fermentation outcomes.

Aromatic Compound Lock-In

Traditional stoneware jars naturally maintain stable temperatures and airflow, enhancing the development and retention of complex aromatic compounds during fermentation. Vacuum fermentation boxes create an anaerobic environment that effectively locks in volatile aromatic molecules, resulting in more intense and consistent flavor profiles.

Traditional Stoneware vs Vacuum Fermentation Box for fermenting. Infographic

cookingdiff.com

cookingdiff.com