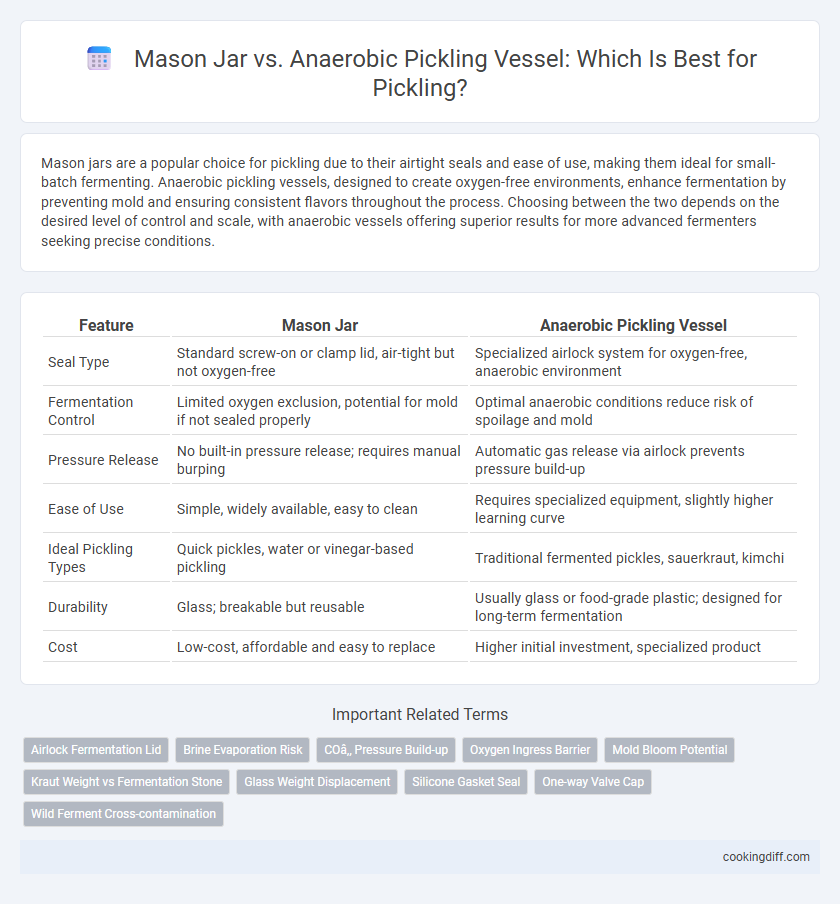

Mason jars are a popular choice for pickling due to their airtight seals and ease of use, making them ideal for small-batch fermenting. Anaerobic pickling vessels, designed to create oxygen-free environments, enhance fermentation by preventing mold and ensuring consistent flavors throughout the process. Choosing between the two depends on the desired level of control and scale, with anaerobic vessels offering superior results for more advanced fermenters seeking precise conditions.

Table of Comparison

| Feature | Mason Jar | Anaerobic Pickling Vessel |

|---|---|---|

| Seal Type | Standard screw-on or clamp lid, air-tight but not oxygen-free | Specialized airlock system for oxygen-free, anaerobic environment |

| Fermentation Control | Limited oxygen exclusion, potential for mold if not sealed properly | Optimal anaerobic conditions reduce risk of spoilage and mold |

| Pressure Release | No built-in pressure release; requires manual burping | Automatic gas release via airlock prevents pressure build-up |

| Ease of Use | Simple, widely available, easy to clean | Requires specialized equipment, slightly higher learning curve |

| Ideal Pickling Types | Quick pickles, water or vinegar-based pickling | Traditional fermented pickles, sauerkraut, kimchi |

| Durability | Glass; breakable but reusable | Usually glass or food-grade plastic; designed for long-term fermentation |

| Cost | Low-cost, affordable and easy to replace | Higher initial investment, specialized product |

Introduction to Pickling Methods

Pickling preserves food by fermentation or by immersing it in an acidic solution, with methods varying based on vessel choice. Mason jars and anaerobic pickling vessels each influence the fermentation environment and final flavor profile.

- Mason Jar - A versatile, airtight glass container commonly used for traditional pickling and canning processes.

- Anaerobic Pickling Vessel - Designed to eliminate oxygen exposure, fostering optimal anaerobic fermentation conditions.

- Pickling Method Impact - Vessel selection affects fermentation speed, flavor development, and preservation quality.

Overview of Mason Jar Pickling

Mason jars are traditional glass containers with a two-piece lid system that creates an airtight seal, making them ideal for pickling. Their wide mouth design allows easy filling and cleaning, which enhances the pickling process by preventing contamination.

These jars are readily available, cost-effective, and reusable, making them a popular choice for home picklers. Mason jars can be used for both fermenting vegetables and preserving pickles through vinegar-based methods, offering versatile pickling solutions.

What Is an Anaerobic Pickling Vessel?

An anaerobic pickling vessel is a specialized container designed to create oxygen-free conditions ideal for fermentation. This vessel minimizes air exposure to enhance flavor development and reduce spoilage risks during the pickling process.

- Oxygen Exclusion - The vessel prevents oxygen from entering, ensuring an anaerobic environment crucial for safe fermentation.

- Airlock System - Equipped with an airlock or valve, it allows gases to escape without letting air in, maintaining consistent anaerobic conditions.

- Material and Design - Typically made of ceramic or glass, the vessel is designed to be airtight and easy to clean, promoting hygiene and durability.

Compared to Mason jars, anaerobic pickling vessels offer a more controlled fermentation environment, leading to improved pickling results.

Key Differences in Design and Function

Mason jars feature a simple glass design with a metal screw-on lid and rubber seal, relying on manual air removal during pickling. Anaerobic pickling vessels incorporate a built-in airlock system that allows gas to escape while preventing oxygen from entering, ensuring an oxygen-free environment.

The key difference lies in oxygen control: Mason jars require careful burping to avoid pressure buildup, whereas anaerobic vessels automatically maintain anaerobic conditions. This reduces the risk of mold and spoilage, enhancing fermentation quality. Anaerobic vessels are typically designed for repeated use with easy gas release, improving safety and convenience in long-term pickling.

Oxygen Exposure: Risks and Benefits

| Pickling Method | Oxygen Exposure | Risks | Benefits |

|---|---|---|---|

| Mason Jar | Allows minimal oxygen exposure due to sealing with airspace | Risk of mold growth and spoilage if not fully submerged or sealed properly | Simple to use and widely available for traditional fermentation |

| Anaerobic Pickling Vessel | Creates near-zero oxygen environment | Requires specialized equipment; spoilage risk reduced but possible if seal fails | Promotes ideal anaerobic fermentation, enhancing flavor and preserving nutrients |

Flavor Development: Impact on Taste

Mason jars allow limited oxygen exposure, which can subtly influence the flavor profile by encouraging mild fermentation and complex taste notes. Anaerobic pickling vessels create a sealed environment that promotes lactic acid bacteria growth, resulting in a more consistent sour and tangy flavor.

- Mason Jar Oxygen Exposure - Small amounts of oxygen can lead to diverse flavor developments due to aerobic microbial activity.

- Anaerobic Environment - Excludes oxygen, fostering lactic acid bacteria that enhance sourness and preserve crispness.

- Flavor Consistency - Anaerobic vessels produce more predictable and stable pickling flavors over time.

Safety Considerations for Home Picklers

Mason jars offer a reliable, airtight seal that prevents contamination during pickling but require careful monitoring to avoid anaerobic spoilage. Anaerobic pickling vessels are specifically designed to maintain an oxygen-free environment, reducing the risk of mold and ensuring safer fermentation. Home picklers should prioritize vessels with secure seals and food-grade materials to minimize health risks and preserve flavor integrity.

Cost Comparison and Accessibility

Mason jars offer a cost-effective and widely accessible option for pickling, with prices typically ranging from $1 to $3 per jar and availability in most supermarkets and online retailers. Anaerobic pickling vessels, designed to create oxygen-free environments for fermentation, usually come at a higher initial cost between $30 and $60 but provide advanced functionality for preserving flavor and texture. While Mason jars are more budget-friendly and convenient for beginners, anaerobic vessels may justify their price for enthusiasts seeking specialized fermentation control.

Cleaning and Maintenance Requirements

Mason jars require thorough cleaning with hot, soapy water and sterilization before each use to prevent contamination during pickling. Their wide mouths facilitate easy access for scrubbing, but rubber seals can harbor bacteria if not regularly inspected and replaced.

Anaerobic pickling vessels often feature airtight seals that minimize oxygen exposure, reducing mold risks but necessitating careful disassembly and cleaning of gaskets and valves. These vessels may require specialized cleaning brushes and periodic sterilization to maintain a fully anaerobic environment crucial for proper fermentation.

Related Important Terms

Airlock Fermentation Lid

Mason jars equipped with airlock fermentation lids provide a simple, cost-effective method for anaerobic pickling by allowing gas to escape while preventing oxygen entry, reducing the risk of mold and spoilage. Anaerobic pickling vessels with integrated airlock systems offer a more controlled fermentation environment, maintaining consistent anaerobic conditions crucial for preserving flavor, texture, and safety in fermented vegetables.

Brine Evaporation Risk

Mason jars, commonly used for pickling, have a higher brine evaporation risk due to their standard lids and occasional air gaps, leading to potential mold growth and inconsistent fermentation. Anaerobic pickling vessels feature airtight seals and water locks that effectively minimize brine evaporation, ensuring a stable environment for optimal fermentation and reduced spoilage risk.

CO₂ Pressure Build-up

Mason jars are popular for pickling but lack a built-in mechanism to release CO2 pressure, increasing the risk of jar breakage or lid popping during fermentation. Anaerobic pickling vessels feature airlocks that safely vent CO2, maintaining a controlled environment and preventing oxygen exposure for optimal fermentation.

Oxygen Ingress Barrier

Mason jars provide a good oxygen ingress barrier with their airtight metal lids and rubber seals, maintaining an anaerobic environment essential for safe pickling. Anaerobic pickling vessels are specifically designed with valves or airlocks that allow gas to escape while preventing oxygen entry, enhancing fermentation control and reducing spoilage risk.

Mold Bloom Potential

Mason jars, while popular for home pickling, have a higher mold bloom potential due to occasional air exposure during sealing, which can introduce oxygen and spoil the ferment. Anaerobic pickling vessels create a sealed, oxygen-free environment that significantly reduces mold growth by maintaining strict anaerobic conditions throughout the fermentation process.

Kraut Weight vs Fermentation Stone

Mason jars offer convenience for small-batch pickling but often require a fermentation stone to keep cabbage submerged, ensuring proper kraut weight and preventing mold. Anaerobic pickling vessels inherently maintain an oxygen-free environment, naturally preserving kraut weight without the need for additional weights like fermentation stones.

Glass Weight Displacement

Mason jars utilize glass weight displacement by placing a heavy glass or ceramic weight inside the jar to keep vegetables submerged in brine, ensuring anaerobic conditions during fermentation. Anaerobic pickling vessels feature built-in weights designed to maintain consistent pressure and prevent air exposure, offering a more reliable and user-friendly method for glass weight displacement.

Silicone Gasket Seal

Silicone gasket seals in Mason jars provide an airtight environment ideal for safe fermentation and extended shelf life during pickling by preventing oxygen exposure. Anaerobic pickling vessels with silicone gaskets enhance this seal with airlock systems that release gas buildup, reducing the risk of spoilage and ensuring consistent anaerobic conditions for optimal fermentation.

One-way Valve Cap

Mason jars equipped with one-way valve caps allow gases to escape during fermentation while preventing oxygen from entering, promoting anaerobic pickling and reducing spoilage risk. Anaerobic pickling vessels often feature specialized one-way valves designed to maintain an oxygen-free environment, enhancing flavor development and preserving safety throughout the fermentation process.

Mason Jar vs Anaerobic Pickling Vessel for pickling. Infographic

cookingdiff.com

cookingdiff.com