Toasting offers consistent heat distribution, resulting in evenly browned surfaces, while infrared grilling provides intense, direct heat that can create hot spots and uneven cooking. The focused heat of infrared grills is ideal for quick searing but may require frequent adjustment to avoid burning or undercooking. Toasting maintains a balanced temperature that ensures uniform crispness across the entire food surface.

Table of Comparison

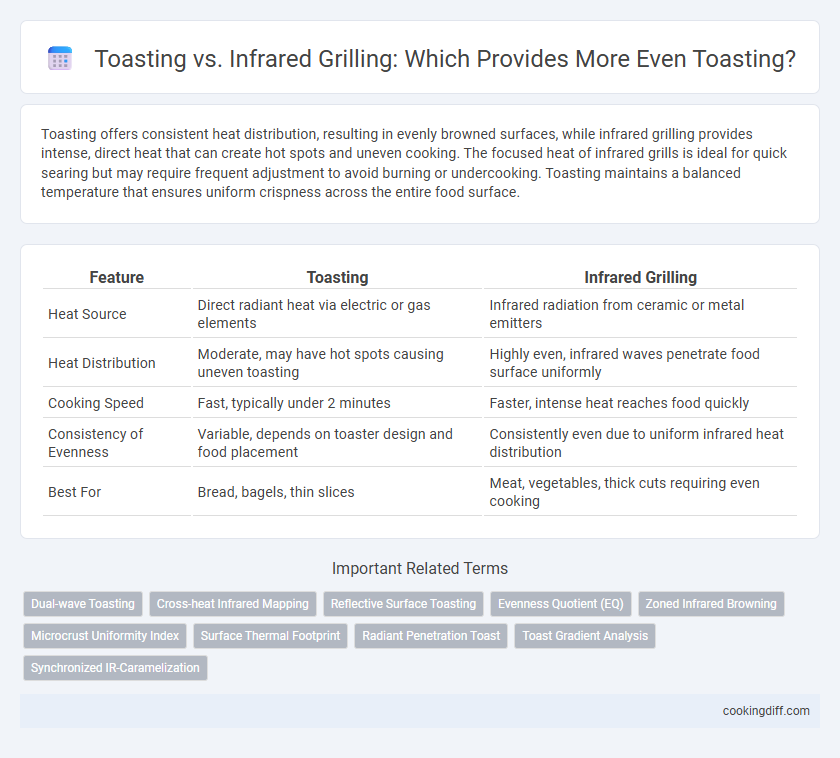

| Feature | Toasting | Infrared Grilling |

|---|---|---|

| Heat Source | Direct radiant heat via electric or gas elements | Infrared radiation from ceramic or metal emitters |

| Heat Distribution | Moderate, may have hot spots causing uneven toasting | Highly even, infrared waves penetrate food surface uniformly |

| Cooking Speed | Fast, typically under 2 minutes | Faster, intense heat reaches food quickly |

| Consistency of Evenness | Variable, depends on toaster design and food placement | Consistently even due to uniform infrared heat distribution |

| Best For | Bread, bagels, thin slices | Meat, vegetables, thick cuts requiring even cooking |

Introduction to Toasting and Infrared Grilling

| Method | Heating Principle | Heat Distribution | Surface Impact |

|---|---|---|---|

| Toasting | Direct contact with radiant heat elements | Moderate; heat typically emanates from one or two sides | Produces crisp, browned surfaces primarily on exposed areas |

| Infrared Grilling | High-intensity infrared radiation | More even and intense heat across the cooking surface | Creates uniform searing and caramelization with less flare-ups |

How Toasting Works: The Science Behind Evenness

Toasting achieves evenness through direct contact and radiant heat, allowing consistent browning across the bread's surface. Infrared grilling relies on electromagnetic waves to heat food, which can create hotspots due to uneven radiation distribution.

- Direct conduction - Toasting uses direct contact with a heated surface, ensuring uniform heat transfer to the bread.

- Radiant heat balance - Toasting combines conduction with even radiant heat, reducing temperature variability across the surface.

- Infrared hotspots - Infrared grills often produce uneven heat zones, causing inconsistent cooking or toasting results.

Understanding heat transfer mechanisms in toasting highlights why it delivers more even results compared to infrared grilling.

Understanding Infrared Grilling Technology

Infrared grilling technology uses radiant heat from infrared burners to cook food evenly by directly heating the cooking surface. This method reduces hot spots and ensures consistent temperature distribution compared to traditional toasting techniques.

- Infrared burners - Emit high-intensity heat waves that penetrate food quickly for uniform cooking.

- Even heat distribution - Infrared grills maintain steady temperatures, minimizing unevenly cooked areas.

- Energy efficiency - Infrared grilling uses less energy by focusing heat precisely where needed on the food surface.

Heat Distribution: Toasting vs Infrared Grilling

Toasting relies on direct radiant heat, which can create uneven browning due to localized hotspots. Infrared grilling uses electromagnetic waves to uniformly penetrate the surface, providing consistent heat distribution across the food. This results in more even cooking and reduces the risk of burnt or undercooked areas compared to traditional toasting methods.

Surface Browning and Maillard Reactions

Toasting provides more consistent surface browning due to direct heat contact, enhancing Maillard reactions evenly across food surfaces. Infrared grilling achieves intense heat that can create deeper caramelization but may result in uneven browning due to localized hot spots.

- Uniform Heat Distribution - Toasting employs steady, distributed heat sources that promote consistent Maillard reactions on the food's surface.

- Intense Localized Heat - Infrared grilling radiates high temperatures, accelerating Maillard browning but risking patchy cooking areas.

- Surface Texture and Flavor - Even toasting enhances texture and flavor development by uniformly initiating Maillard chemistry without burning.

Assessing Evenness: Visual and Taste Comparisons

How does toasting compare to infrared grilling in terms of evenness? Toasting often provides surface crispness but may lack the consistent heat distribution of infrared grilling, which delivers uniform cooking through rapid and even heat transfer. Visual inspections reveal more evenly browned surfaces with infrared grilling, while taste tests highlight a balance of texture and flavor better preserved by this method.

Pros and Cons: Toasting for Uniform Results

Toasting provides consistent heat distribution by surrounding the bread with direct contact heat, resulting in uniform browning and a crisp texture. Infrared grilling, while offering intense and quick heat, can cause uneven cooking due to hotspots and lack of surface contact. Toasting is preferable for achieving even results when uniform crispness and color are essential, despite infrared grilling's advantage in speed.

Pros and Cons: Infrared Grilling for Consistency

Infrared grilling offers superior heat distribution due to its direct radiant heat, resulting in more consistent toasting compared to traditional methods. This precise temperature control minimizes hot spots, ensuring even browning across the entire surface.

However, infrared grills can be more expensive and require a learning curve to master optimal heat settings. Their intense heat may char foods quickly if not carefully monitored, potentially leading to uneven crisping in delicate items. Maintenance and cleaning are also more demanding due to higher operating temperatures and specialized components.

Practical Tips for Achieving Even Cooking

Toasting evenly requires consistent heat distribution, which traditional toasters achieve through interior heating elements positioned around the bread. Infrared grilling, however, uses radiant heat that penetrates food more deeply and uniformly, reducing hotspots and ensuring a balanced cook.

Practical tips for toasting include preheating the toaster and using slices of similar thickness for uniform browning. For infrared grilling, maintain a steady temperature and use a grilling surface that reflects heat evenly to optimize even cooking results.

Related Important Terms

Dual-wave Toasting

Dual-wave toasting utilizes a combination of short and long infrared waves to achieve superior evenness compared to conventional infrared grilling, reducing hotspots and ensuring consistent browning across the entire surface. This technology enhances heat distribution by penetrating food evenly, resulting in perfectly toasted bread with uniform color and texture.

Cross-heat Infrared Mapping

Cross-heat infrared mapping reveals that toasting achieves more consistent heat distribution compared to standard infrared grilling, minimizing hot spots and ensuring even browning across the surface. This precise thermal control enhances the texture and flavor of toasted foods by promoting uniform caramelization and reducing the risk of uneven cooking.

Reflective Surface Toasting

Reflective surface toasting enhances evenness by directing radiant heat uniformly across the food, preventing hot spots common in traditional toasting methods. Infrared grilling provides intense, focused heat but may create uneven cooking due to its directional energy, making reflective surface toasting superior for balanced, consistent browning.

Evenness Quotient (EQ)

Toasting achieves a high Evenness Quotient (EQ) by uniformly applying radiant heat to the bread's surface, minimizing hotspots and ensuring consistent browning. Infrared grilling, while effective for high-heat cooking, often produces uneven heat distribution that lowers its EQ, causing variable toasting results compared to traditional toasting methods.

Zoned Infrared Browning

Zoned infrared browning in toasting delivers precise, evenly distributed heat that minimizes hotspots, outperforming traditional infrared grilling by ensuring consistent surface caramelization. This method intensifies flavor through controlled heat zones, creating uniform crust development and superior browning without overcooking the interior.

Microcrust Uniformity Index

The Microcrust Uniformity Index (MUI) indicates that toasting achieves a more consistent crust formation across the food surface compared to infrared grilling, which tends to produce uneven browning due to hotspot variations. Enhanced MUI values in toasting are attributed to uniform heat distribution and controlled airflow, resulting in superior textural quality and flavor consistency.

Surface Thermal Footprint

Toasting provides a concentrated surface thermal footprint ideal for evenly crisping bread with minimal heat loss, while infrared grilling offers a broader thermal distribution that can result in uneven heat application. The precise, focused heat of toasting ensures consistent browning across the surface compared to the variable thermal zones typical in infrared grilling.

Radiant Penetration Toast

Radiant penetration toast from infrared grilling delivers superior evenness by deeply heating the bread's interior along with its surface, reducing cold spots and ensuring uniform browning. In contrast, traditional toasting relies primarily on surface heat, which can cause uneven crispness and less consistent texture throughout the slice.

Toast Gradient Analysis

Toast gradient analysis reveals that toasting provides a more uniform heat distribution across the bread surface compared to infrared grilling, which often causes uneven hotspots. This results in consistent browning and optimal texture development in toasting, enhancing flavor and visual appeal.

Toasting vs Infrared grilling for evenness. Infographic

cookingdiff.com

cookingdiff.com