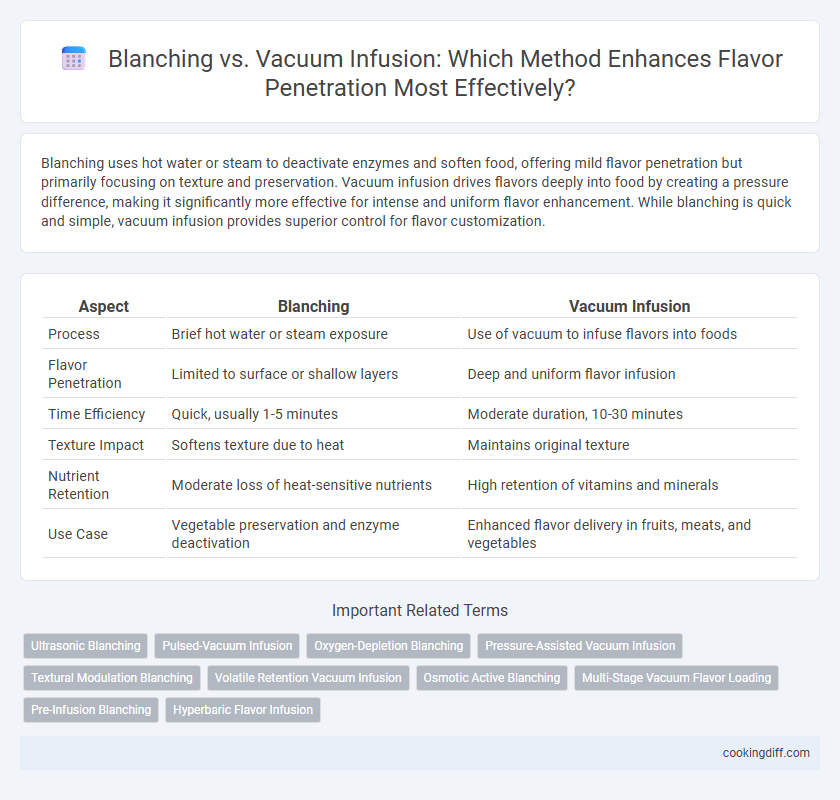

Blanching uses hot water or steam to deactivate enzymes and soften food, offering mild flavor penetration but primarily focusing on texture and preservation. Vacuum infusion drives flavors deeply into food by creating a pressure difference, making it significantly more effective for intense and uniform flavor enhancement. While blanching is quick and simple, vacuum infusion provides superior control for flavor customization.

Table of Comparison

| Aspect | Blanching | Vacuum Infusion |

|---|---|---|

| Process | Brief hot water or steam exposure | Use of vacuum to infuse flavors into foods |

| Flavor Penetration | Limited to surface or shallow layers | Deep and uniform flavor infusion |

| Time Efficiency | Quick, usually 1-5 minutes | Moderate duration, 10-30 minutes |

| Texture Impact | Softens texture due to heat | Maintains original texture |

| Nutrient Retention | Moderate loss of heat-sensitive nutrients | High retention of vitamins and minerals |

| Use Case | Vegetable preservation and enzyme deactivation | Enhanced flavor delivery in fruits, meats, and vegetables |

Introduction to Flavor Penetration Techniques

Blanching and vacuum infusion are two distinct flavor penetration techniques used in food preparation. Blanching involves briefly boiling food to halt enzymatic activity, while vacuum infusion uses reduced pressure to enhance flavor absorption.

Blanching primarily prepares ingredients by softening textures and preserving color, which can slightly open food pores for mild flavor uptake. Vacuum infusion forces flavorful liquids into the cellular structure, achieving deeper and faster flavor penetration. This technique is particularly effective for dense or porous foods where rapid and uniform seasoning is desired.

What is Blanching?

Blanching is a cooking process involving brief exposure of food to boiling water or steam, primarily used to preserve color, texture, and nutritional value. It differs from vacuum infusion, which infuses flavors by applying vacuum pressure to force liquids into food.

- Heat Application - Blanching uses high temperature for a short duration to inactivate enzymes and halt cooking processes.

- Flavor Impact - It minimally affects flavor penetration compared to vacuum infusion, which actively introduces flavors into the food's structure.

- Purpose - Blanching prepares foods for freezing, drying, or further cooking by stabilizing their characteristics rather than enhancing taste.

Understanding Vacuum Infusion

Vacuum infusion enhances flavor penetration by creating a pressure differential that draws liquids into food tissues more effectively than blanching, which mainly softens and cooks the surface. This process preserves the texture and nutrients while infusing flavors uniformly.

- Vacuum infusion utilizes low pressure - It removes air from food pores, allowing liquids to penetrate deeper for stronger flavor integration.

- Blanching involves brief high-temperature exposure - It primarily softens food and reduces microbial load but does not significantly enhance internal flavor absorption.

- Vacuum infusion maintains food structure - This results in a better mouthfeel compared to the textural changes caused by blanching.

Mechanisms of Flavor Penetration in Blanching

How does blanching facilitate flavor penetration at the cellular level? Blanching uses hot water or steam to disrupt cell membranes, increasing permeability and allowing flavors to penetrate more effectively into fruits and vegetables. This thermal treatment also inactivates enzymes that could degrade flavor compounds, preserving the intended taste profile during further processing.

Flavor Infusion Process in Vacuum Techniques

Vacuum infusion enhances flavor penetration by creating a low-pressure environment that opens food pores, allowing marinades and seasonings to deeply permeate the cells more effectively than blanching. Unlike blanching, which primarily uses heat to alter texture and flavor superficially, vacuum techniques preserve nutritional value while accelerating the absorption of flavors. This controlled infusion process results in more intense and uniform taste profiles, improving overall food quality and consumer satisfaction.

Comparing Efficiency: Blanching vs Vacuum Infusion

| Method | Efficiency of Flavor Penetration | Key Advantages |

|---|---|---|

| Blanching | Moderate flavor penetration achieved through brief exposure to hot water or steam, altering cell walls to enhance infusion capacity. | Improves texture and color, reduces enzyme activity, and prepares food for further processing with partial flavor absorption. |

| Vacuum Infusion | High efficiency in flavor penetration by creating a vacuum that forces flavors deep inside the food's cellular structure within minutes. | Ensures uniform and rapid flavor distribution, maintains nutrient integrity, and allows precise control over infusion parameters. |

Impact on Texture and Nutrition

Blanching involves briefly immersing food in boiling water or steam, which can soften texture and cause some nutrient loss, particularly water-soluble vitamins. Vacuum infusion uses reduced pressure to force flavors into food without significant heat exposure, better preserving texture firmness and nutritional content. Comparing both methods, vacuum infusion offers superior flavor penetration while maintaining the original texture and nutrients more effectively than blanching.

Suitable Ingredients for Each Method

Blanching is ideal for firm vegetables like green beans and broccoli, enhancing texture and preparing them for flavor absorption. Vacuum infusion suits porous foods such as fruits and spongy vegetables, enabling deeper flavor penetration through controlled pressure changes.

- Blanching excels with dense vegetables - It softens cell walls to allow surface seasoning absorption.

- Vacuum infusion targets porous ingredients - It forces marinades deep into produce like strawberries or mushrooms.

- Texture considerations guide method selection - Firm vegetables benefit from blanching, while tender items respond best to vacuum infusion.

Choosing between blanching and vacuum infusion depends on ingredient structure for optimal flavor enhancement.

Equipment and Practical Considerations

Blanching equipment typically involves large steamers or hot water baths designed for rapid heat application to inactivate enzymes and preserve color, requiring substantial energy input and precise temperature control. Vacuum infusion equipment consists of vacuum chambers and infusion tanks that facilitate flavor penetration by creating pressure differentials, offering greater control over infusion depth and uniformity.

From a practical standpoint, blanching is faster and suitable for high-throughput processing but may cause nutrient loss and texture changes due to heat exposure. Vacuum infusion, although slower and requiring specialized apparatus, enhances flavor retention and customization while minimizing nutrient degradation, making it ideal for artisanal and specialty food production.

Related Important Terms

Ultrasonic Blanching

Ultrasonic blanching significantly enhances flavor penetration compared to traditional vacuum infusion by disrupting cell structures and promoting deeper infusion of marinades or seasonings. This technology improves mass transfer rates and preserves sensory qualities, making it more effective for achieving uniform and intense flavor profiles in processed foods.

Pulsed-Vacuum Infusion

Pulsed-vacuum infusion enhances flavor penetration by alternating vacuum and atmospheric pressure, allowing deeper and more uniform infusion compared to traditional blanching, which primarily uses heat to inactivate enzymes and soften tissues. This method improves texture retention while significantly increasing the rate and extent of flavor compound absorption in fruits and vegetables.

Oxygen-Depletion Blanching

Oxygen-depletion blanching enhances flavor penetration by reducing oxidative enzymes and retaining volatile compounds better than traditional blanching methods. Unlike vacuum infusion, which injects flavors under reduced pressure, oxygen-depletion blanching preserves natural taste by minimizing oxygen exposure during heat treatment, improving texture and sensory quality.

Pressure-Assisted Vacuum Infusion

Pressure-assisted vacuum infusion enhances flavor penetration by creating a low-pressure environment that forces marinades deeper into food tissues compared to traditional blanching, which primarily softens textures with limited infusion capability. This method optimizes infusion efficiency by combining vacuum pressure with controlled atmospheric conditions, resulting in more uniform and intense flavor absorption.

Textural Modulation Blanching

Blanching rapidly softens plant cell walls through brief heat exposure, enhancing textural modulation by partially gelatinizing pectin and reducing enzymatic activity, which helps maintain crispness and color. Compared to vacuum infusion, blanching offers more uniform texture control by stabilizing surface tissues before flavor compounds penetrate, resulting in improved mouthfeel while preserving structural integrity.

Volatile Retention Vacuum Infusion

Vacuum infusion enhances flavor penetration by significantly improving volatile retention compared to blanching, which often leads to the loss of essential aromatic compounds due to heat exposure. This technique maintains the integrity of flavor volatiles by reducing oxidation and evaporation during processing, resulting in more intense and fresh-tasting food products.

Osmotic Active Blanching

Osmotic Active Blanching uses a hypertonic solution to enhance flavor penetration by promoting cell membrane permeability and facilitating solute exchange, resulting in deeper infusion compared to Vacuum Infusion, which relies on pressure differentials to introduce flavors. The osmotic gradients in Osmotic Active Blanching achieve more uniform and controlled flavor uptake, optimizing texture and taste retention during subsequent cooking processes.

Multi-Stage Vacuum Flavor Loading

Multi-Stage Vacuum Flavor Loading enhances flavor penetration more effectively than traditional blanching by creating successive vacuum cycles that drive deeper infusion of marinades and seasonings into food matrices. This process preserves texture and nutritional quality while achieving uniform and intensified taste profiles, outperforming blanching which often results in surface-level flavor absorption and nutrient loss.

Pre-Infusion Blanching

Pre-infusion blanching enhances flavor penetration by disrupting cell walls and inactivating enzymes, which facilitates deeper absorption during vacuum infusion. This thermal treatment ensures uniform texture and preserves the natural taste, improving overall infusion efficiency compared to vacuum infusion alone.

Blanching vs Vacuum Infusion for flavor penetration Infographic

cookingdiff.com

cookingdiff.com